Maximize Performance And Life

The performance and life of couplings depend largely upon

how you install and maintain them. Before installing couplings,

make certain that foundations of equipment to be connected

meet manufacturers’ requirements. Check for soft foot. The use

of stainless steel shims is recommended. Measuring

misalignment and positioning equipment within alignment

tolerances is simplified with an alignment computer. These

calculations can also be done graphically or mathematically.

Alignment is shown using spacer bar and straight edge. This

practice has proven to be adequate for many industrial

applications. However, for superior final alignment, the use of

dial indicators

(see Manual 458-834 for instructions),

alignment computers or graphical analysis is recommended.

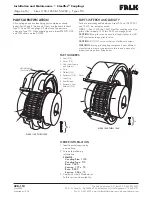

1— Mount Seals And Hubs

Lock out starting switch of prime mover. Clean all metal parts

using a non-flammable solvent. Lightly coat seals with grease

and place on shafts BEFORE mounting hubs. Heat hubs as

previously instructed.

Seal keyways to prevent leakage

. Mount

hubs on their respective shafts so the hub face is flush with the

end of its shaft unless otherwise indicated.

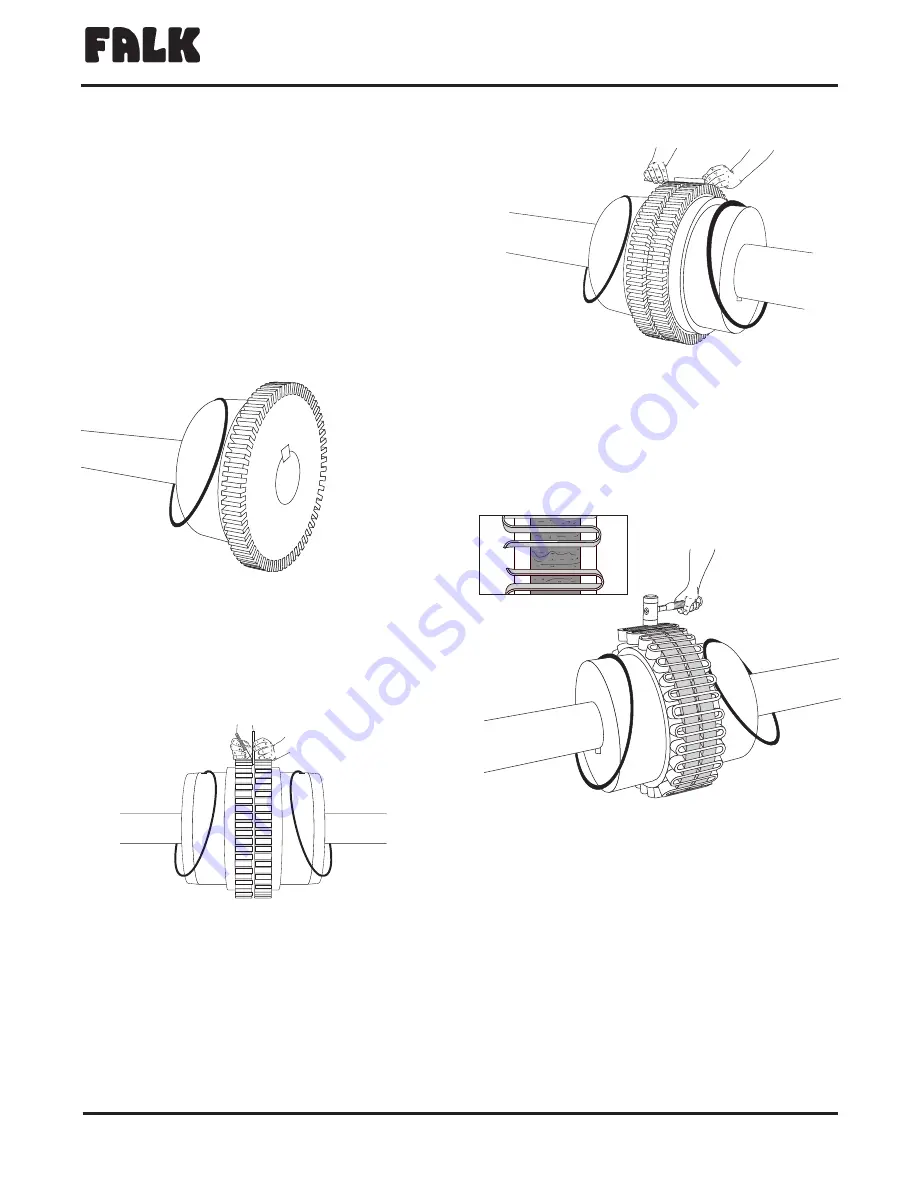

2 — Gap and Angular Alignment

Use a spacer bar equal in thickness to the gap specified in

Insert bar as shown above, to same depth at

90° intervals and measure clearance between bar and hub

face with feelers. The difference in minimum and maximum

measurements must not exceed the ANGULAR INSTALLATION

3 — Offset Alignment

Align so that a straight edge rests squarely (or within the limits

) on both hubs as shown above and also at

90° intervals. Check with feelers. The clearance must not

exceed the PARALLEL OFFSET installation limits specified in

Tighten all foundation bolts and repeat Steps 2 and 3.

Realign coupling if necessary. NOTE: Use a dial indicator for

more accurate alignment.

4 — Insert Grid

Pack gap and grooves with specified lubricant before inserting

grid. When grids are furnished in two or more segments, install

them so that all cut ends extend in the same direction (as detailed

in the exploded view picture above); this will assure correct grid

contact with non-rotating pin in cover halves. Spread the grid

slightly to pass over the coupling teeth and seat with a soft mallet.

®

The Falk Corporation, P.O. Box 492, Zip 53201-0492

428-112

3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone: 414-342-3131

May 2000

Fax: 414-937-4359 e-mail: falkinfo@falkcorp.com web: www.falkcorp.com

Supersedes 12-98

Steelflex

®

Couplings

•

Installation and Maintenance

Type T10

•

Sizes 1150–1260 & 150–260

(Page 3 of 6)

MOUNT

SEAL

FIRST