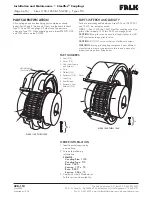

TYPE T COUPLING INSTALLATION &

ALIGNMENT DATA

Maximum life and minimum maintenance for the coupling and

connected machinery will result if couplings are accurately

aligned. Coupling life expectancy between initial alignment

and maximum operating limits is a function of load, speed and

lubrication.

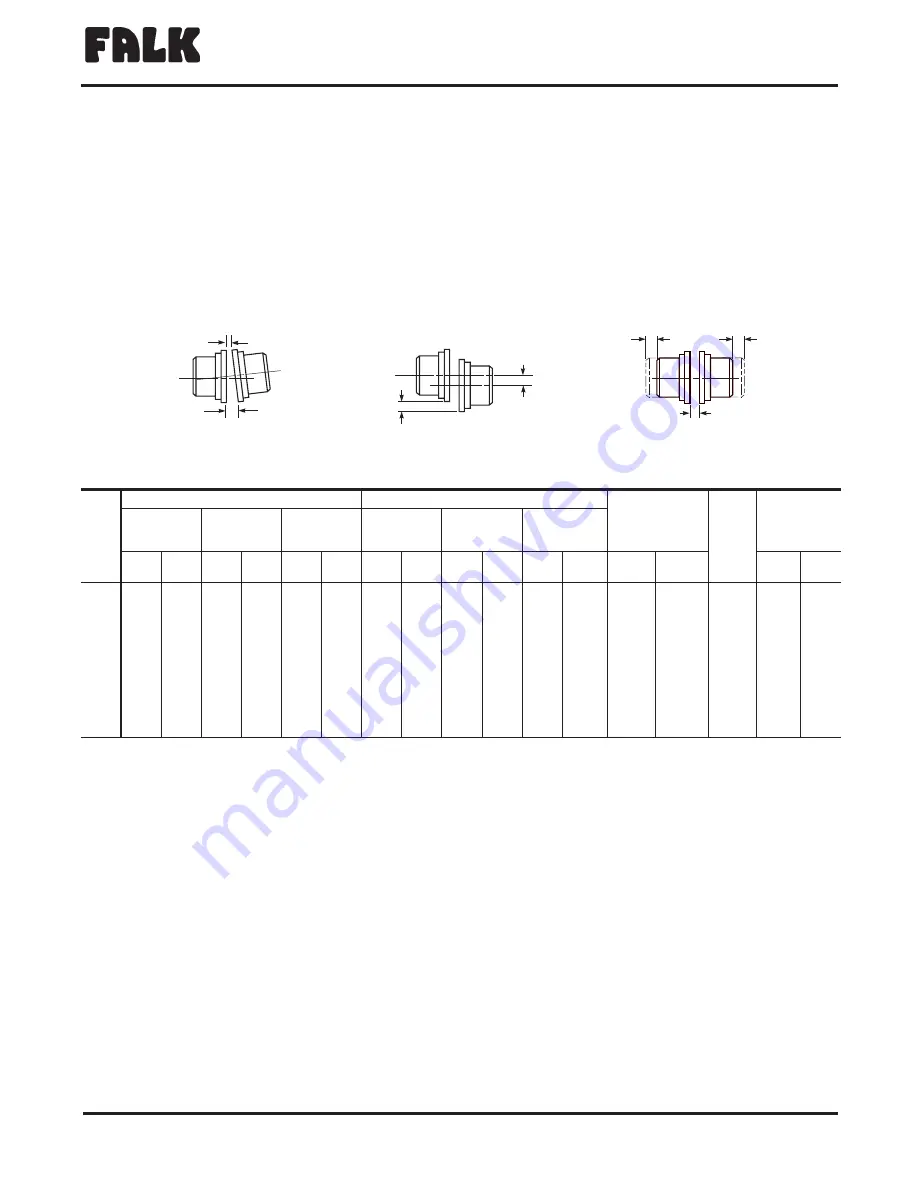

Values may be combined for an installation or operating condition.

Example: 1180T max. operating misalignment is .030" parallel

plus .089" angular.

NOTE: For applications requiring greater misalignment, refer

application details to the Factory.

Angular misalignment is dimension X minus Y as illustrated below.

Parallel misalignment is distance P between the hub center

lines as illustrated below.

End float (with zero angular and parallel misalignment) is the axial

movement of the hubs(s) within the cover(s) measured from “O” gap.

®

The Falk Corporation, P.O. Box 492, Zip 53201-0492

428-112

3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone: 414-342-3131

May 2000

Fax: 414-937-4359 e-mail: falkinfo@falkcorp.com web: www.falkcorp.com

Supersedes 12-98

Steelflex

®

Couplings

•

Installation and Maintenance

Type T10

•

Sizes 1150–1260 & 150–260

(Page 5 of 6)

TABLE 2 — Misalignment And End Float

CPLG

SIZE

Installation Limits

Operating Limits

Cover Fastener

Tightening

Torque Values

Allow

Speed

(rpm)

Lube Wt

Parallel

Offset-P

Angular

(x-y)

Normal Gap

±

10%

Parallel

Offset-P

Angular

(x-y)

End Float

Physical Limit

(Min) 2 x F

Max

In.

Max

mm

Max

In.

Max

mm

In.

mm

Max

In.

Max

mm

Max

In.

Max

mm

In.

mm

lb-in

Nm

lb

kg

1150T

.012

.305

.016

.406

.250

6

.024

.610

.062

1.57

.620

15.7

650

73.4

1500

4.3

1.95

1160T

.012

.305

.018

.457

.250

6

.024

.610

.070

1.79

.640

16.3

650

73.4

1350

6.2

2.81

1170T

.012

.305

.020

.508

.250

6

.024

.610

.079

2.01

.617

15.7

1300

146.9

1225

7.7

3.49

1180T

.015

.381

.022

.559

.250

6

.030

.762

.089

2.26

.717

18.2

1300

146.9

1100

8.3

3.76

1190T

.015

.381

.024

.610

.250

6

.030

.762

.097

2.46

.620

15.7

1300

146.9

1050

9.7

4.40

1200T

.015

.381

.027

.686

.250

6

.030

.762

.107

2.72

.620

15.7

2300

259.9

900

12.4

5.62

1210T

.018

.457

.029

.737

.500

13

.036

.914

.118

3.00

1.02

25.9

2300

259.9

820

23.2

10.5

1220T

.018

.457

.032

.813

.500

13

.036

.914

.129

3.28

1.15

29.2

3580

404.5

730

35.4

16.1

1230T

.019

.483

.035

.889

.500

13

.038

.965

.142

3.61

1.12

28.4

3580

404.5

680

53.0

24.0

1240T

.019

.483

.038

.965

.500

13

.038

.965

.154

3.91

1.12

28.4

5350

604.5

630

74.5

33.8

1250T

.020

.508

.042

1.07

.500

13

.040

1.02

.169

4.29

1.12

28.4

5350

604.5

580

110.5

50.1

1260T

.020

.508

.046

1.17

.500

13

.040

1.02

.183

4.64

1.01

25.7

5350

604.5

540

148.1

67.2

GAP

Y

X

F

F

ANGULAR MISALIGNMENT

P

P

PARALLEL OFFSET MISALIGNMENT

END FLOAT