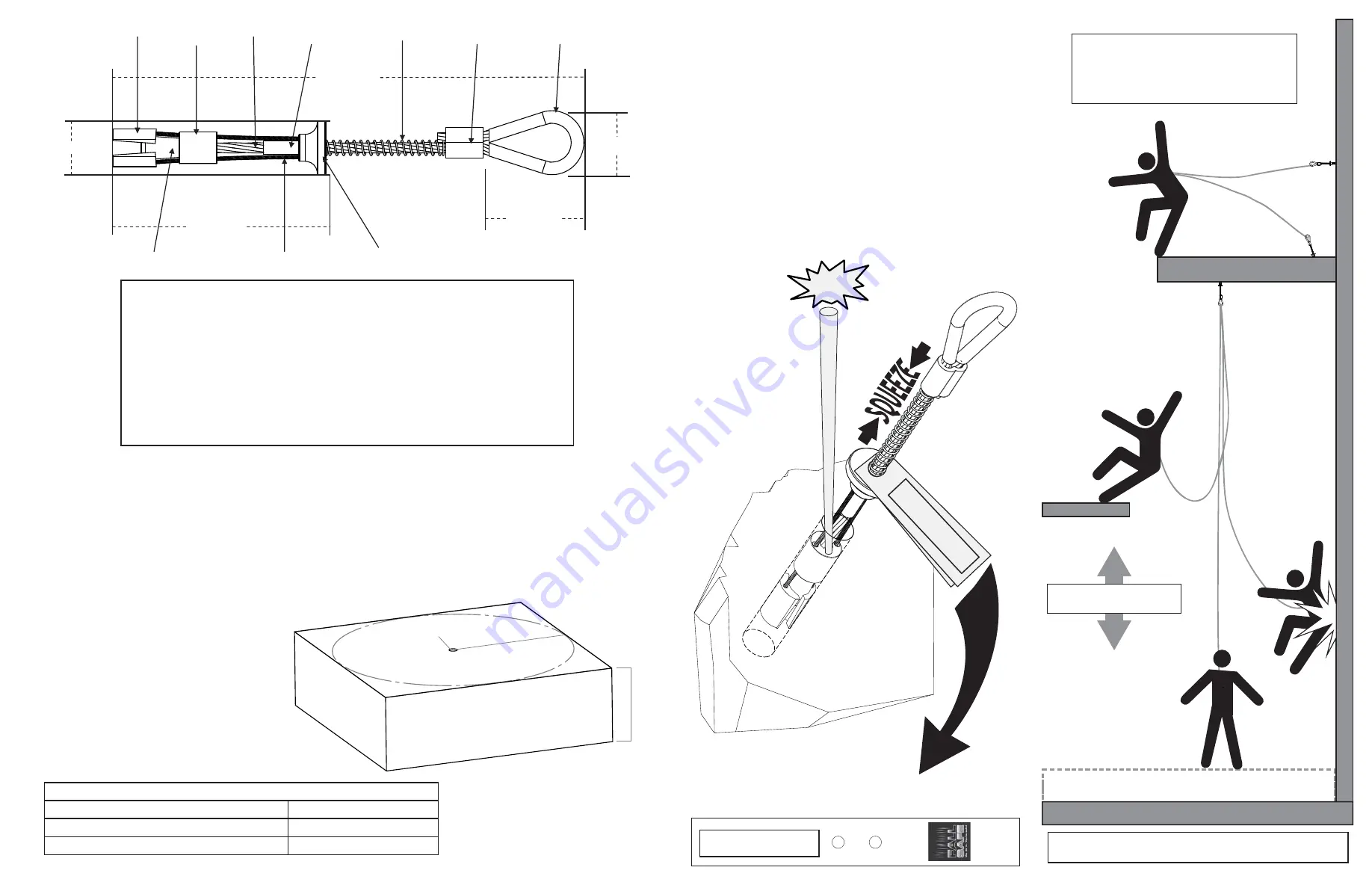

DRILLING & INSTALLATION INSTRUCTIONS:

1. Drill a 3/4” (20mm) diameter hole at least 3.5” (89mm) deep. The drilled hole must be straight and perpendicular to

the surface. Make sure the hole is of uniform diameter and free of peaks and valleys on the inner wall.

2. Blow hole clean with compressed air.

3. Always inspect the hole carefully when reusing a previously drilled hole.

4. When placing anchor, place your thumb inside the anchor loop and your first two fingers around the trigger.

Squeeze fingers and thumb together till the trigger and spring fully compress.

4. Insert unit at least 3” (76mm) deep into hole and release the trigger. Do not force.

5. Set the unit with a slight tug on the anchor loop.

6. The stop sleeve must always be partially inserted into the hole.

All products subjected to fall arresting forces should be removed

from service immediately!

DECK/FLOOR/GROUND LEVEL

WORK SURFACE

(ANCHOR POINT)

MINIMUM CLEARANCE 3ft (1m)

W

A

RNING!!! SWING F

ALLS C

AN OC

CUR

WHEN

THE

W

ORKER IS NO

T DIREC

TL

Y UNDER ANCHOR POINT

.

Free fall distance (limit) must

not exceed 6’ ft (1.8 m).

The concrete must be

3000-psi or higher and

fully cured. Installation

location to be approved

by a qualified person.

Performance:

Static tensile strength:

5000-lbf

(

22kN) minimum.

Maximum capacity:

one worker with

max weight of

310-lbs when used as

a single point anchorage connector

for personal fall arrest or restraint

Dimensions:

Weight:

0.4-lbs (.18kg)

Length:

11.5” (293mm)

Diameter:

0.75” (20mm)

Regulatory compliance:

ANSI Z

359.1-2007, ANSI Z359.7-2011 and OSHA

1926.502 CE 0321 / EN

795:1996 (+A1:2000) Class B

Component Materials:

Main Cable:

Aircraft Cable.

End Termination:

Stainless Steel.

Spoons:

Stainless Steel.

Stop Sleeve:

Stainless Steel.

Trigger:

Aluminum.

Spring:

Zinc Plated Steel.

Swage:

Zinc

Plated Copper.

Return Wire:

Aircraft Cable.

Loop Cover:

Polyurethane.

Spoon

Cleaning Bushing

Spring

Swage

Anchor Loop

Heavy Duty Return Wire

Stop Sleeve

End Termination

Trigger

1.25” (31mm)

3.0” (76mm)

5.0” (127mm)

11.5” (293mm)

Main Cable

2” (50.8mm)

REMOVAL INSTRUCTIONS:

1. When removing anchor, place your thumb inside the anchor loop

and your first two fingers around the trigger. Squeeze fingers and

thumb together till the trigger and spring fully compress.

2. While squeezing the trigger pull the anchor out of the hole.

3. If the anchor becomes stuck, insert a punch, screwdriver or other

object into the hole until it touches the top of the cleaning bushing.

4. Lightly tap with a hammer making sure the tool is touching the top

of the cleaning bushing while squeezing the trigger. (The cleaning

bushing should be easily visible at the edge of the hole).

5. If tool was required to remove the anchor inspect thoroughly for

damage after removal. If damage is found remove from service and

destroy immediately.

WORK SURFACE

May be used as a anchoring point for a leading

edge restraint system. Examples are of optional

anchoring point locations. The use of two anchors

is not required for leading edge restraint systems

unless otherwise specified by the manufacturer.

OPTIONAL

(ANCHOR POINTS)

TAP!!!

D

O N

OT R

EM

OVE

Stainless Ste

el, Al

uminum,

Zinc Plate

d Cop

per

, 7x1

9 Ai

rcr

af

t C

ab

le

WA

RNIN

G

!!!

AL

L P

ERS

ONS

U

SI

NG

THI

S E

QU

IP

ME

NT

MU

ST

RE

AD

AND

UN

DE

RS

TAN

D

AL

L IN

ST

RU

CT

IO

NS

.

FA

ILU

RE

TO

D

O

SO

MA

Y R

ES

ULT

IN

SE

RI

OU

S INJ

URY

OR

DE

AT

H.

US

ERS

SHOU

LD

BE

FA

MIL

IAR

W

IT

H

PE

RT

IN

EN

T REGU

LA

TIO

NS

GOVE

RN

IN

G T

HIS

EQU

IP

ME

NT

. A

LL

INDI

VI

DU

AL

S WH

O

US

E

TH

IS

PRO

DU

CT

MU

ST

BE

PROP

ERL

Y INS

TRU

CT

ED

ON

HOW T

O

US

E T

HI

S D

EVICE

.

C

om

plian

ce:

OSHA

1

92

6.50

2 &

191

0.66 /

AN

S

I Z35

9.1

C

E

0

321

/

E

N

79

5:

199

6

(+

A1:

200

0)

C

la

ss B

DO NOT REMOVE

WARNING LABEL!

(A)”

drill

3/4”

Ø

min from

any edge

(B)”

HOLE DRILLING REQUIRMENT CHART

(A)” Minimum distance from edge/corner

(B)” Concrete thickness

6” in. (15.3 cm)

12” in. (30.5 cm)

12” in. (30.5 cm)

5” in. (12.7 cm)

DO NOT REMOVE

Reusable Bolt

Anchor

Model: FS881

+351 252 480 060

Stainless Steel, Aluminum, Zinc Plated Copper, 7x19 Aircraft Cable

WARNING!!!

ALL PERSONS USING THIS EQUIPMENT MUST READ AND UNDERSTAND ALL INSTRUCTIONS.

FAILURE TO DO SO MAY RESULT IN SERIOUS INJURY OR DEATH. USERS SHOULD BE FAMILIAR

WITH PERTINENT REGULATIONS GOVERNING THIS EQUIPMENT. ALL INDIVIDUALS WHO USE

THIS PRODUCT MUST BE PROPERLY INSTRUCTED ON HOW TO USE THIS DEVICE.

Compliance: OSHA 1926.502 & 1910.66 / ANSI Z359.1, ANSI Z359.7

CE 0321 / EN 795:1996 (+A1:2000) Class B

RB5-xxx / mm/yyyy

INSPEC

T BEFORE USE

(Max Capacity 310-lbs)

V1.3