6.0 Maintenance, Service, and Storage

6.1

Maintenance: Ensure the winch is kept free of excess paint, grease, dirt, or other contaminants. Clean the exterior of the unit as required

with a detergent/water solution. Do not allow water other corrosion causing elements to enter the gears. After cleaning, pull the

lifeline all the way out, allow the unit to air dry, then rewind the lifeline into the unit.

Apply a thin coat of number 2 lithium grease to the winch gears occasionally.

DO NOT use heat to dry.

DO NOT attempt to disassemble the winch.

6.2

Service: If service is required for any reason; inspection failure, or any type of malfunction, tag the unit as “UNUSABLE”, store separately,

and contact FallTech at 323-752-0066 to receive a Return Authorization number or to locate the nearest FallTech Service Center. The

winch is not user repairable. Only the manufacturer, or a repair facility authorized in writing, may make repairs to the winch.

6.3

Storage: Store the winch in a cool, dry, clean environment out of direct sunlight. Avoid exposure to chemical or caustic vapors. Thoroughly

inspect the winch after any period of extended storage.

7.0 Inspection

7.1

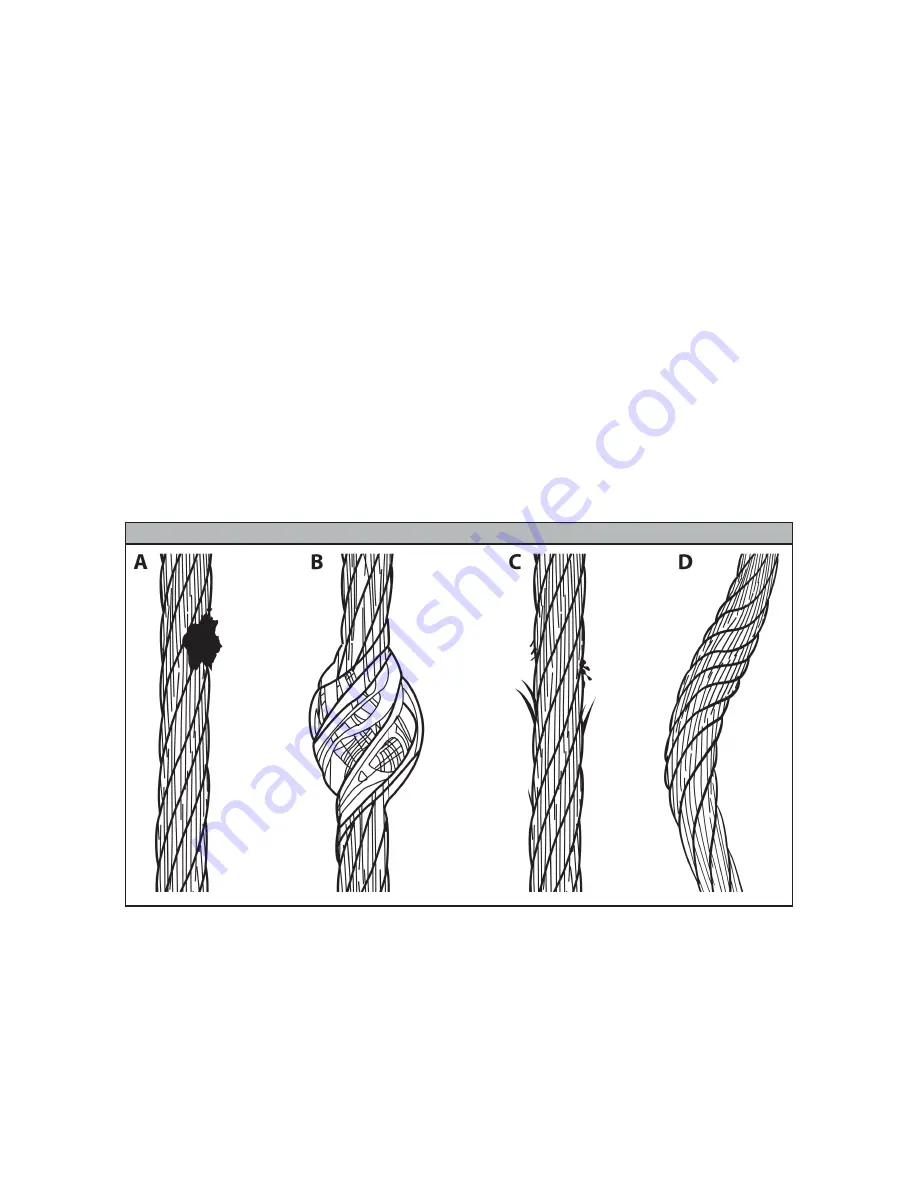

Pre-Use User Inspection Wire Rope: Prior to each use, inspect the entire unit, including the leg end connector, for signs of corrosion,

cracks, deformities, and broken, or missing parts. Inspect the wire rope for cuts, abrasions, weld spatter, arc damage, fishhooks, broken

strands, kinks, bird caging, any type of debris.

A thorough inspection of the wire rope should be made at least once a month. This is performed by unreeling of all the wire rope from

the winch. Using gloves, extract all of the cable and check the entire working length for damage caused by chemical corruption or

excessive heat as evident by discoloration (A), bird caging (B), broken wire strands (C), kinks and bent strands (D), see Figure 5. Rewind the

cable onto the drum, in accordance with the procedures in this manual. If the cable bird nests or over rides onto itself, crank the cable

out, remedy the cause, and rewind the cable.

Figure 5: Inspection of Cable

Rewind the cable onto the drum, in accordance with the procedures in this manual. If the cable bird nests or over rides onto itself, unwind

the cable out, remedy the cause, and rewind the cable.

Inspect the labels to be sure they are present and legible.

An inspection by a competent person other than the user is required every six months in accordance with the procedures in this manual.

If routine inspection reveals an unsafe condition, remove it from service.

Record the results of each inspection on the Inspection Log provided or in another suitable place.

10

MCS13 Rev B

022420