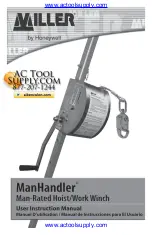

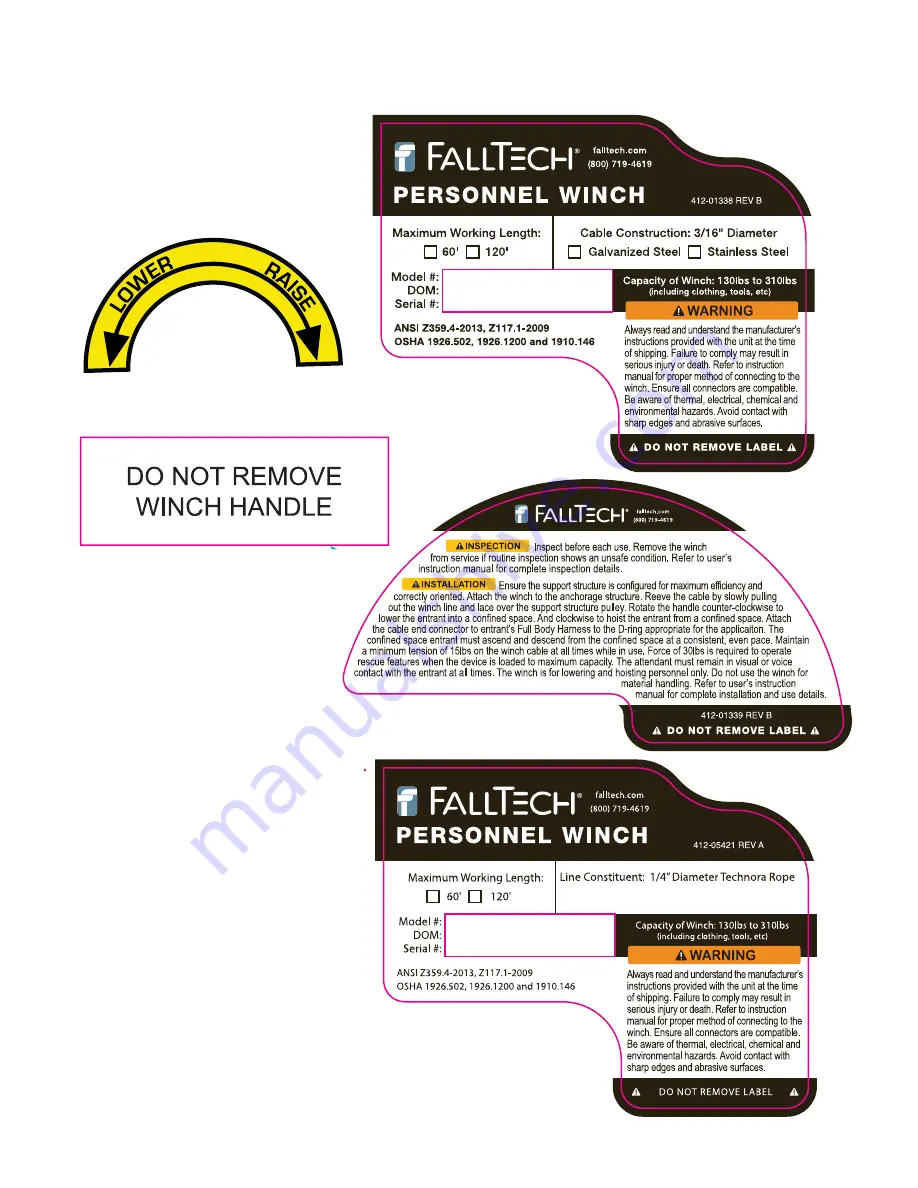

8.0 Labels

The labels must be present and legible.

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

A

B

C

D

E

F

A

B

C

D

E

F

REV

TITLE

ITEM NO.

SIZE

SHEET

SCALE

Label, Personnel Winch

Label 1

412-01338

REVISIONS

REV

DRAWN

DATE

A PRELIMINARY INITIAL RELEASE

DESCRIPTION

THE INFORMATION EMBODIED IN THIS DOCUMENT IS STRICTLY

CONFIDENTIAL AND ARE SUPPLIED WITH THE UNDERSTANDING

THAT THEY WILL NOT BE DISCLOSED TO THIRD PARTIES

1:1

1/1

A

B

GENERAL NOTES:

1.

2.

3.

4.

WEIGHT (FOR REFERENCE ONLY)

N/A

N/A

N/A

Ed Gabrielyan

N/A

N/A

N/A

Poly Carbonate Coated Vinyl

APPLICABLE STANDARDS:

ASME Y14.5-2009 & DIN ISO 2768

EXCEPTION: TRAILING ZEROS DENOTE

TOLERANCE

UNLESS OTHERWISE SPECIFIED DIMENSIONS

ARE IN MILLIMETERS (mm)

TOLERANCES ARE:

0 to 6 ...........................................

6 to 30 .........................................

30 to 120 .....................................

120 + ...........................................

ANGLES ......................................

APPROVED

MFG

CHECKED

SURFACE ROUGHNESS

SURFACE FINISH

12/26/18

MATERIAL

COLORS

DRAWN

N/A

N/A

N/A

0.1

0.2

0.3

0.5

0.5

PANTONE BLACK C

PANTONE 5415 C

PANTONE 144 C

Editable

*Actual Size*

Outlined

*Actual Size*

DIELINE

CUTOUT LOCATION DIMS

MAIN DIELINE DIMS

DO NOT PRINT

DO NOT REMOVE LABEL

Always read and understand the manufacturer’s

instructions provided with the unit at the time

of shipping. Failure to comply may result in

serious injury or death. Refer to instruction

manual for proper method of connecting to the

winch. Ensure all connectors are compatible.

Be aware of thermal, electrical, chemical and

environmental hazards. Avoid contact with

sharp edges and abrasive surfaces.

PERSONNEL WINCH

412-01338 REV B

Model #:

DOM:

Serial #:

Maximum Working Length:

60'

120'

Cable Construction: 3/16" Diameter

Galvanized Steel

Stainless Steel

ANSI Z359.4-2013, Z117.1-2009

OSHA 1926.502, 1926.1200 and 1910.146

Capacity of Winch: 130lbs to 310lbs

(including clothing, tools, etc)

falltech.com

(800) 719-4619

A PRELIMINARY INITIAL RELEASE

09/12/17

SAM

B UPDATED ARTWORK

01/21/19

ED

100mm

80mm

14.5mm

10.5mm

40mm x 10mm CUTOUT

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

A

B

C

D

E

F

A

B

C

D

E

F

REV

TITLE

ITEM NO.

SIZE

SHEET

SCALE

Label, Personnel Winch

Label 2

412-01339

REVISIONS

THE INFORMATION EMBODIED IN THIS DOCUMENT IS STRICTLY

CONFIDENTIAL AND ARE SUPPLIED WITH THE UNDERSTANDING

THAT THEY WILL NOT BE DISCLOSED TO THIRD PARTIES

1:1

1/1

A

B

GENERAL NOTES:

1.

2.

3.

4.

WEIGHT (FOR REFERENCE ONLY)

N/A

N/A

N/A

Ed Gabrielyan

N/A

N/A

N/A

Poly Carbonate Coated Vinyl

APPLICABLE STANDARDS:

ASME Y14.5-2009 & DIN ISO 2768

EXCEPTION: TRAILING ZEROS DENOTE

TOLERANCE

UNLESS OTHERWISE SPECIFIED DIMENSIONS

ARE IN MILLIMETERS (mm)

TOLERANCES ARE:

0 to 6 ...........................................

6 to 30 .........................................

30 to 120 .....................................

120 + ...........................................

ANGLES ......................................

APPROVED

MFG

CHECKED

SURFACE ROUGHNESS

SURFACE FINISH

12/26/18

MATERIAL

COLORS

DRAWN

N/A

N/A

N/A

0.1

0.2

0.3

0.5

0.5

PANTONE BLACK C

PANTONE 108 C

REV

DRAWN

DATE

A PRELIMINARY INITIAL RELEASE

DESCRIPTION

09/12/17

SAM

B UPDATED ARTWORK

01/21/19

ED

PANTONE 5415 C

Editable

*Actual Size*

Outlined

*Actual Size*

DO NOT REMOVE LABEL

Inspect before each use. Remove the winch

from service if routine inspection shows an unsafe condition. Refer to user’s

instruction manual for complete inspection details.

Ensure the support structure is configured for maximum efficiency and

correctly oriented. Attach the winch to the anchorage structure. Reeve the cable by slowly pulling

out the winch line and lace over the support structure pulley. Rotate the handle counterclockwise to

lower the entrant into a confined space. And clockwise to hoist the entrant from a confined space. Attach

the cable end connector to entrant’s Full Body Harness to the D-ring appropriate for the applicaiton. The

confined space entrant must ascend and descend from the confined space at a consistent, even pace. Maintain

a minimum tension of 15lbs on the winch cable at all times while in use. Force of 30lbs is required to operate

rescue features when the device is loaded to maximum capacity. The attendant must remain in visual or voice

contact with the entrant at all times. The winch is for lowering and hoisting personnel only. Do not use the winch for

material handling. Refer to user’s instruction

manual for complete installation and use details.

INSPECTION

INSTALLATION

412-01339 REV B

falltech.com

(800) 719-4619

116mm

60mm

DIELINE

MAIN DIELINE DIMS

DO NOT PRINT

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

A

B

C

D

E

F

A

B

C

D

E

F

REV

TITLE

ITEM NO.

SIZE

SHEET

SCALE

Winch Rotation Label

1133ALX

REVISIONS

REV

DRAWN

DATE

P1 PRELIMINARY INITIAL RELEASE

DESCRIPTION

-

-

THE INFORMATION EMBODIED IN THIS DOCUMENT IS STRICTLY

CONFIDENTIAL AND ARE SUPPLIED WITH THE UNDERSTANDING

THAT THEY WILL NOT BE DISCLOSED TO THIRD PARTIES

1:1

1/1

A

P1

WEIGHT (FOR REFERENCE ONLY)

N/A

N/A

N/A

Samuel Andrade

N/A

N/A

N/A

Polycarbonate coated vinyl

APPLICABLE STANDARDS:

ASME Y14.5-2009 & DIN ISO 2768

EXCEPTION: TRAILING ZEROS DENOTE

TOLERANCE

UNLESS OTHERWISE SPECIFIED DIMENSIONS

ARE IN MILLIMETERS (mm)

TOLERANCES ARE:

0 to 6 ...........................................

6 to 30 .........................................

30 to 120 .....................................

120 + ...........................................

ANGLES .....................................

APPROVED

MFG

CHECKED

SURFACE ROUGHNESS

SURFACE FINISH

8-17-2016

MATERIAL

DRAWN

N/A

N/A

N/A

0.1

0.2

0.3

0.5

0.5

13

MCS13 Rev B

022420