4.1

Capacity: The capacity of the winch is one worker between 130 lbs to 310 lbs. (140 kg) including tools, clothing, etc.

4.2

Compatibility Of Connectors: Connectors are considered compatible with connecting elements when they have been designed to work

together in such a way that their sizes and shapes do not cause their gate mechanisms to open inadvertently, regardless of how they

become oriented. Contact FallTech if you have any questions about compatibility. Connectors must be compatible with the anchorage or

other system components. Do not use equipment that is not compatible. Non-compatible connectors may unintentionally disengage.

Connectors must be compatible in size, shape, and strength. Self-closing, self-locking snap hooks and carabiners are required by OSHA.

4.0 System Requirements

4.3

Compatibility Of Components: Equipment is designed for use with approved components and subsystems only. Substitutions or

replacements made with non-approved components or subsystems may jeopardize compatibility of equipment and may affect the safety

and reliability of the complete system.

4.4

Making Connections: Only use self-locking connectors with this equipment. Only use connectors that are suitable to each application.

Ensure all connections are compatible in size, shape, and strength. Do not use equipment that is not compatible. Visually ensure all

connectors are fully closed and locked. Connectors are designed to be used only as specified in each product’s user’s instructions.

4.5

Personal Fall Arrest System: A PFAS is an assembly of components and subsystems used to arrest a person during a fall event. A PFAS

is typically composed of an anchorage and a FBH, with an energy absorbing connecting device, i.e., an SAL, an SRD, or a Fall Arrester

Connecting Subsystem (FACSS), connected to the dorsal D-ring of the FBH. PFAS components used in conjunction with this SRD should

comply with ANSI Z359 requirements and applicable OSHA regulations.

4.5.1 PFAS Anchorage Strength: The winch shown in Table 1 is listed as having a minimum tensile strength of 5,000 lbs. To maintain

OSHA compliance, the structure where the unit is installed must be capable of supporting at least 5,000 lbs, or be designed, installed and

used as part of a PFAS, which maintains a safety factor of at least 2:1, under the supervision of a qualified person.

4.5.2 Work Positioning: Work positioning requires an anchorage capable of supporting 5,000 lbs applied in the direction permitted by the

system.

4.5.3 Personnel Riding: A structure used for personnel riding, lowering and hoisting must be able to support a static load of 2,500 lbs

applied in the direction permitted by the system.

4.5.4 Rescue: A structure used for rescue must be able to support a static load of 2,500 lbs applied in the direction permitted by the

system.

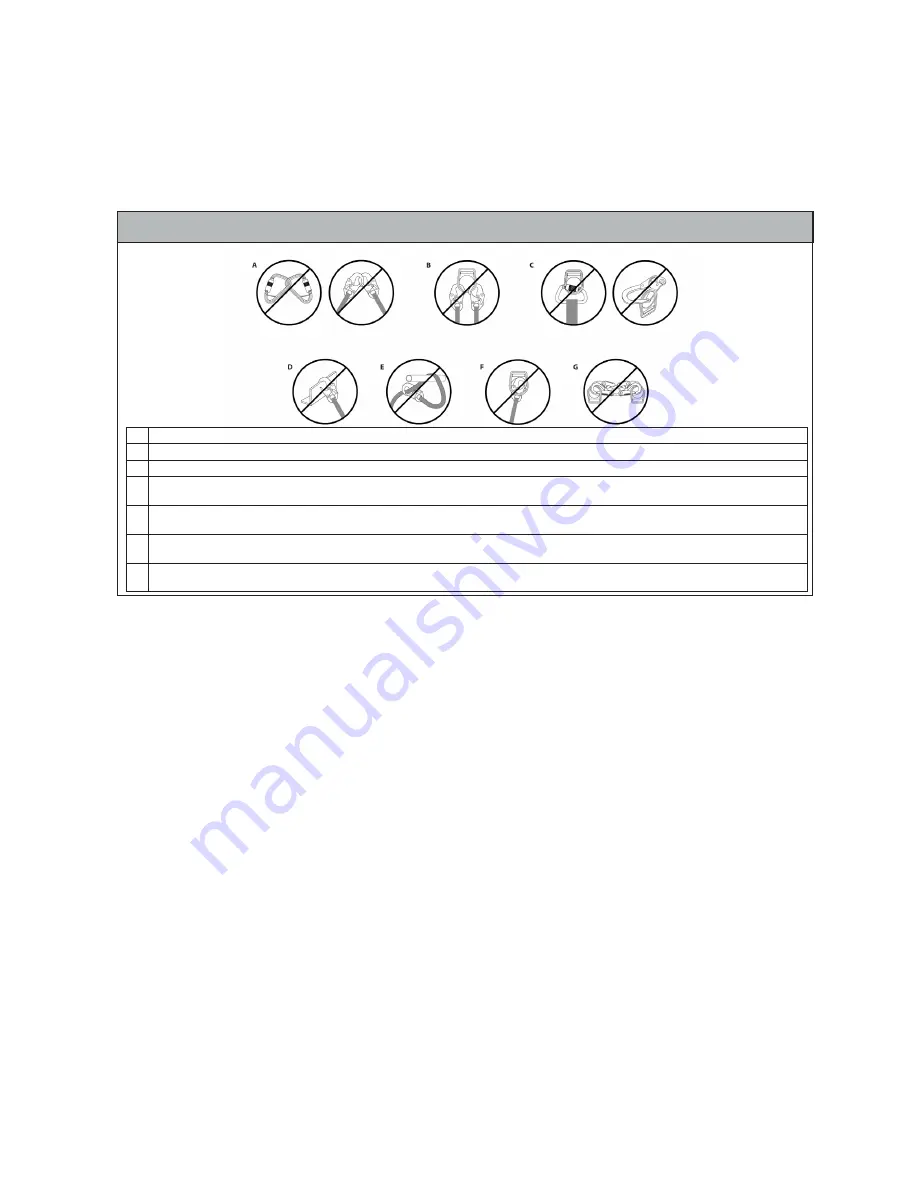

A Never connect two active components (snap hooks or carabiners) to each other.

B Never connect two active components (snap hooks or carabiners) to a single D-ring at the same time.

C Never connect in a way that would produce a condition of loading on the gate.

D Never attach to a object in a manner whereby the gate (of the snap hook or carabiner) would be

prevented from fully closing and locking. Always guard against false connections by visually inspecting for closure and lock.

E

Never attach explicitly to a constituent subcomponent (webbing, cable or rope) unless specifically provided for by the manufacturer’s instructions for both

subcomponents (snap hook or carabiner and webbing, cable or rope).

F

Never attach in a manner where an element of the connector (gate or release lever) may become caught on the anchor thereby producing additional risk of

false engagement.

G Never attach a spreader snap hook to two side/positioning D-rings in a manner whereby the D-rings will engage the gates; the gates on a spreader must

always be facing away from the D-rings during work positioning.

Figure 2 - Non-Compatible Connections

5

MCS13 Rev B

022420