5.3

Use of the Winch: Inspect the winch and line constituent before each use in accordance with the procedures in Section 7 of this

manual. Ensure the cable or rope are in proper working order, with no damage or deformities. See Section 7 for inspection criteria.

Ensure the support structure is configured for maximum efficiency, and correctly oriented. The device should be at a comfortable height

for use. Adjust device bracket if necessary. For more information see instruction manuals MCS07 for tripods or MCS30 for the davit.

Attach the winch leg end connector to the entrant’s dorsal D-ring of the full body harness.

To raise a load, rotate the winch handle in the clockwise direction.

To suspend a load, release the handle and the brake will suspend the load until further action is needed. Do not exceed the rated capacity

of 310lbs.

To lower a load, rotate the crank handle counterclockwise to lower the entrant into a confined space. The handle will rotate

approximately one revolution before the load starts to lower. If the secondary brake is engaged, raise the load approximately one turn of

the drum before attempting to lower the load.

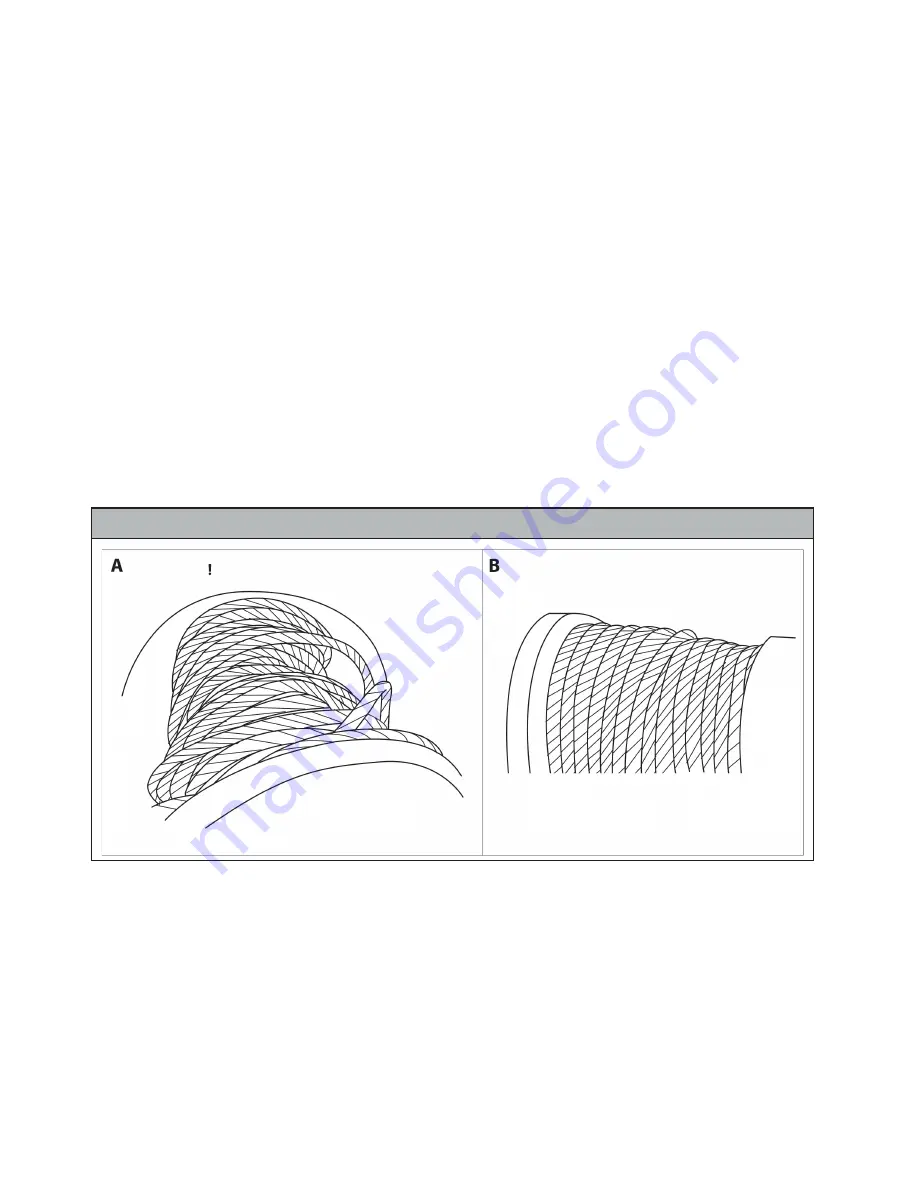

NOTE: Maintain 15 lbs of tension in both directions on the cable at all times to ensure proper functioning and to prevent bird nesting of

the cable on the drum. See Figure 4. The entrant must ascend and descend from the confined space at a consistent, even pace. The

attendant must remain in visual or voice contact with the entrant at all times.

When the crank handle stops turning, the internal friction brake will hold the load without crank rotation. If the winch exhibits signs of

load slip or erratic functioning due to wear or overheating of the brake, remove the winch from service. When hoisting, the winch will

make a clicking sound. Ensure the cable lies evenly on the drum, with no over-lay. With a gear ratio of 5:1, 15 lbs of force on the winch

handle, at a cranking rate of one revolution per second, will yield a hoist rate of 12 ft/min. Ensure working lines are free of entanglement

and contact with sharp edges. The winch is not a fall protection device and must not be subjected to fall arrest forces.

Use of the winch for suspension or personnel riding requires a back-up fall protection system, see Appendix C.

For additional information on confined space, see Appendix C of this manual.

CORRECT

INCORRECT

Figure 4 - Correct and Incorrect Cable Placement

Incorrect- Avoid Bird’s Nesting of Cable

Correct- Even Cable Placement

9

MCS13 Rev B

022420