4.0 Installation and Use

4.1

Plan the Personal Fall Arrest System (PFAS):

Inspect the HLL subsystem before each use in accordance with the procedures detailed in

Section 6. Examine the work area and take action to address hazards. Falls are a serious hazard when working at height. Training and

equipment are the tools of fall hazard management. There are several closely related facets of fall hazard management with a PFAS;

•

Anchor Point Selection

•

Anchorage Connector

•

Deceleration Device

•

Maximum Arrest Force

•

Deceleration Distance

•

Minimum Required Fall Clearance (MRFC)

•

Body Wear

• Rescue

4.2

Anchor Point Selection:

Select a suitable anchor point. Consider the area where the work is being performed. In an overhead anchorage

condition, the area below the anchorage is the work zone. Lateral movement away from the anchorage is hazardous. As distance from

the anchor increases, the work zone expands, and so does the hazard. Work zone expansion is measured in feet and has a direct influence

on user safety. Always work as close to the anchor as possible.

If used in applications with leading edge hazards, anchorage locations must be selected so that the deflected HLL shall not come in

contact with a leading edge in the event of a fall. For below D-ring anchor point installations for use with this HLL system, contact

FallTech at info@falltech.com.

4.3

Anchorage Connector:

Anchorage Connectors used as part of a PFAS should be designed for use with specified anchor points and

compatible with the PFAS components and connectors to be used in the assembly of a complete PFAS. Care should be taken to ensure

proper assembly, installation and maintenance of all Anchorage Connectors to be used when planning a PFAS. Failure to inspect,

assemble, install and/or maintain Anchorage Connectors could result in injury or death.

4.4

Connectors/Deceleration Devices:

Connectors and Deceleration Devices such as Shock Absorbing Lanyards, Self-Retracting

Devices/Lifelines, and Fall Arrestor Connector Subsystems (Vertical Lifeline/Rope Grab Combinations) are designed to connect the user’s

body wear to the Anchorage Connector and/or Anchor Point of a Personal Fall Arrest System.

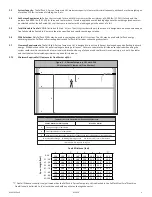

3.3

Compatibility of Components:

Equipment is designed for use with approved components and subsystems only. Substitutions or

replacements made with non-ANSI Z359 compliant components or subsystems may jeopardize compatibility of equipment and may affect

the safety and reliability of the complete system. Ensure compatibility between the connectors if non-FallTech components are used for

fall protection, see Figure 7.

3.4

Connectors:

Only use self-locking snap hooks, rebar hooks, and carabiners with this equipment. Only use connectors that are suitable to

each application. Ensure all connections are compatible in size, shape and strength. Do not use equipment that is not compatible. Visually

ensure all connectors close and lock completely. Connectors (snap hooks, rebar hooks, and carabiners) are designed for use only

as specified in this manual.

MHLL05 Rev A

012920

10

A

Never connect two active components (snap hooks or carabiners) to each other.

B

Never connect two active components (snap hooks or carabiners) to a single D-ring at the same time.

C

Never connect in a way that would produce a condition of loading on the gate.

D

Never attach to a object in a manner whereby the gate (of the snap hook or carabiner) would be

prevented from fully closing and locking. Always guard against false connections by visually inspecting for closure and lock.

E

Never attach explicitly to a constituent subcomponent (webbing, cable or rope) unless specifically provided for by the manufacturer’s instructions for both

subcomponents (snap hook or carabiner and webbing, cable or rope).

F

Never attach in a manner where an element of the connector (gate or release lever) may become caught on the anchor thereby producing additional risk of

false engagement.

G

Never attach a spreader snap hook to two side/positioning D-rings in a manner whereby the D-rings will engage the gates; the gates on a spreader must

always be facing away from the D-rings during work positioning.

Figure 7 - Incorrect Connections