2.0 Application

2.1

The FallTech 4-Person Temporary HLL provides horizontal mobility for workers exposed to fall hazards and is designed as an anchorage

subsystem for the attachment of up to four PFASs. The HLL is adjustable up to 100’ in length for a single span system and is

designed to be used as part of a complete PFAS. See Figure 1.

When properly tensioned, the lifeline will react to a fall event of up to four workers by combining the energy absorbing properties of the

lifeline energy absorber, the lifeline, and the worker’s personal energy absorber. During a fall event, the the stretch of the lifeline and the

expansion of the user’s PFAS will result in reduced forces to the anchor and to the user’s body.

2.2

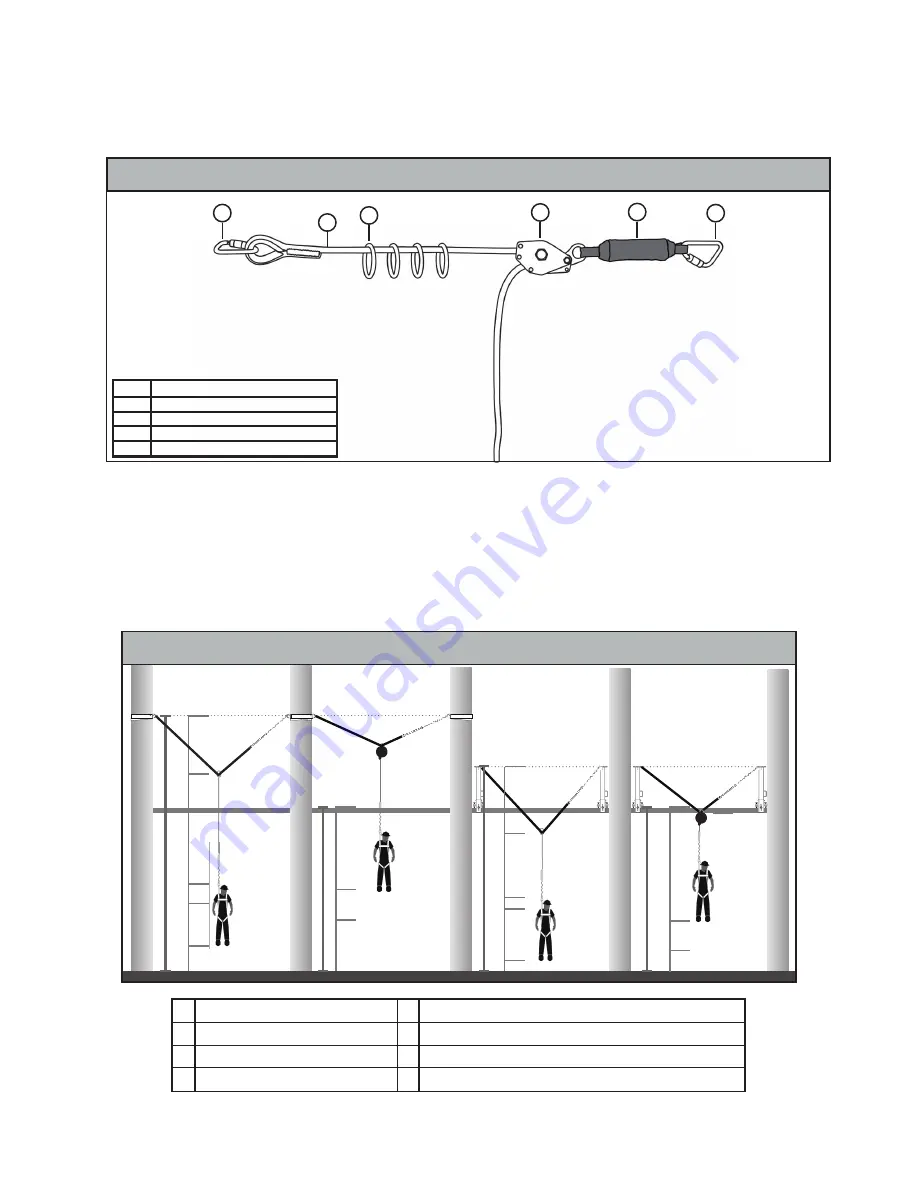

Application Limits:

The FallTech 4-Person Temporary HLL is a dynamic anchorage subsystem that will vary in its performance depending

upon the length of the system, the number of workers attached and the type of PFAS being used. Care should be taken to understand the

capacity of the system, minimum required fall clearance, anchorage strength requirements, total allowable free fall, total allowable

fall clearance, and how the user’s PFAS will deploy during a fall event. Longer HLL spans will generate more lifeline deflection and sag

during a fall event and will result in greater clearance requirements. See Figure 2.

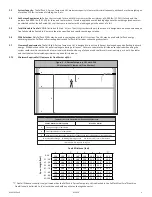

Figure 1 - About the 4-Person Temporary HLL

A

B

A

Carabiner

B 4-Person HLL Rope

C

O-Rings x4

D

Tensioner

E Energy Absorber

A

Deployed In-Line Energy Absorber E Height of Worker

B Dynamic Lifeline Sag

F

Safety Factor

C

Deployed EAL

G

Total Required Fall Clearance

D D-ring Shift and Harness Stretch

H

Total SRD Deceleration Distance from User’s Manual*

* If SRD Deceleration Distance is unknown in overhead applications, use 2 feet for ANSI Z359.14

Class A SRDs or use 4-1/2 feet for ANSI Z359.14 Class B SRDs.

Figure 2 - Clearance Requirements

A

A

A

A

G

G

G

G

B

B

B

B

C

C

D

D

E

E

F

F

F

F

H

H

D

D

A

C

D

MHLL05 Rev A

012920

4

E