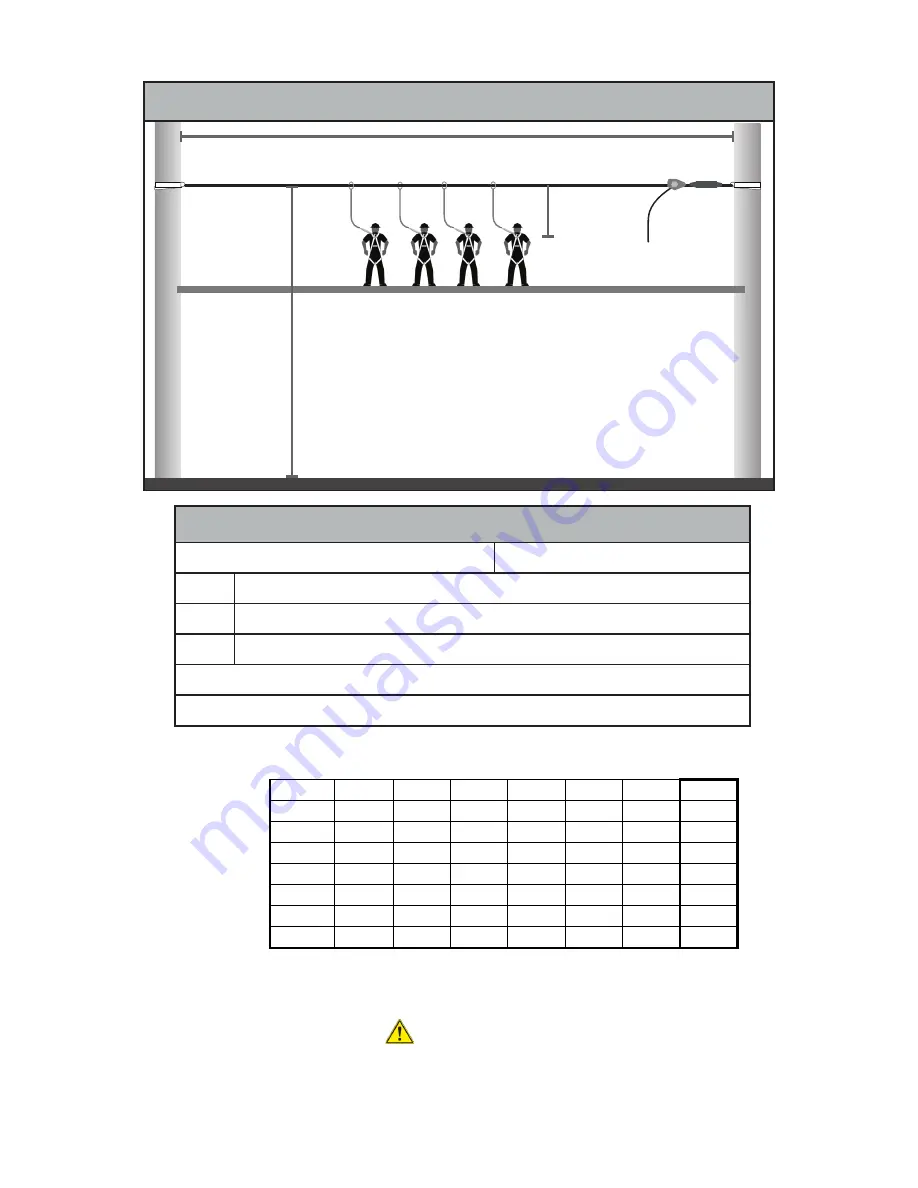

Span Leng

th (

fee

t)

Freefall Distance (feet)

0

1

2

3

4

5

6

7 *

0 - 30

19

.5’

20.5’

21.5’

22.5’

23.5’

24.5’

25.5’

26

.5’

31 - 40

20

.5’

21.5’

22.5’

23.5’

24.5’

25.5’

26.5’

27.5’

41 - 50

22.0

’

23.0’

24.0’

25.0’

26.0’

27.0’

28.0’

29.0’

51 - 60

23.5

’

24.5’

25.5

’

26.5’

27.5’

28.5’

29.5’

30.5’

61 - 70

25.5

’

26.5’

27.5’

28.5’

29.5’

30.5’

31.5’

32.5’

71 - 80

28.0

’

29.0’

30.0’

31.0’

32.0

’

33.0’

34.0’

35.0’

81 - 90

31.0

’

32.0’

33.0’

34.0’

35.0’

36.0’

37.0’

38.0’

91 - 100

34.0

’

35.0’

36.0’

37.0’

38.0’

39.0’

40.0’

41

.0’

Temporary HLL with EAL Minimum Required Fall Clearance

310 lbs. Maximum User Capacity Each

Max. Four Workers

1

Find Span Length in Table Below

2

Find Freefall Distance in Table Below

3

Required Fall Clearance at the intersection of Span Length and Freefall Distance (see table below)

A.

Overhead Anchorage

B.

Walking/Working Surface

C.

Nearest Lower Level or Obstruction

* Work below HLL to avoid Swing Fall

2.7.3

Minimum Required Fall Clearance for Three or Four Workers w/EAL

MHLL05 Rev A

012920

7

1

2

3

B

C

A

Figure 5 - 4-Person Temporary HLL with EALs

Minimum Fall Clearance (Three or Four Workers)

* 7’ Freefall Distance scenario is only allowed when the FallTech 4-Person Temporary HLL is attached to the FallTech SteelGrip

®

Stanchion.

Freefall should be limited to 6’ or less when used with any other anchorage connector.

When a worker falls while connected to the horizontal lifeline, the system will deflect. If two or more workers are connected to

the same horizontal lifeline, and one worker falls, the other workers may be pulled off the walking-working surface. The poten

-

tial for the other workers falling increases as the lifeline length increases. The use of independent HLL systems for each person or

shorter span lengths is recommended to minimize the potential of the other workers falling.

WARNING