021519

MCS30 Rev B

4

2.1

Purpose: The Confined Space Davit is designed to work as part of a system to raise or lower a person or material to work in a confined

space for entry, retrieval, fall arrest applications, and material handling. The Confined Space Davit is a modular design and allows

multiple configurations with optional Davit Arms, Lower Mast Extensions, and Bases.

2.2

Application Limits: The FallTech Confined Space Davit is a dynamic anchorage system that will vary in its performance depending upon

configured offset. Care should be taken to understand the capacity of the system and anchorage strength requirements.

2.3

System Capacity: The maximum capacity of the Confined Space Davit is one worker for confined space entry and egress, with the

worker weighing no more than 310lbs (140kg) including clothing, tools, etc. For rescue applications, the Confined Space Davit has a

maximum capacity of two workers with each worker weighing no more than 310lbs including clothing, tools, etc.

2.4

Davit Anchorage Strength: When using the FallTech Confined Space Davit with the 3-Piece Portable Base, the mounting surface must

support 5000lbs. When using the FallTech Confined Space Davit with any other base, please refer to the user instruction manual

for the specific base.

2.0 Application

3.0 System Requirements

3.1

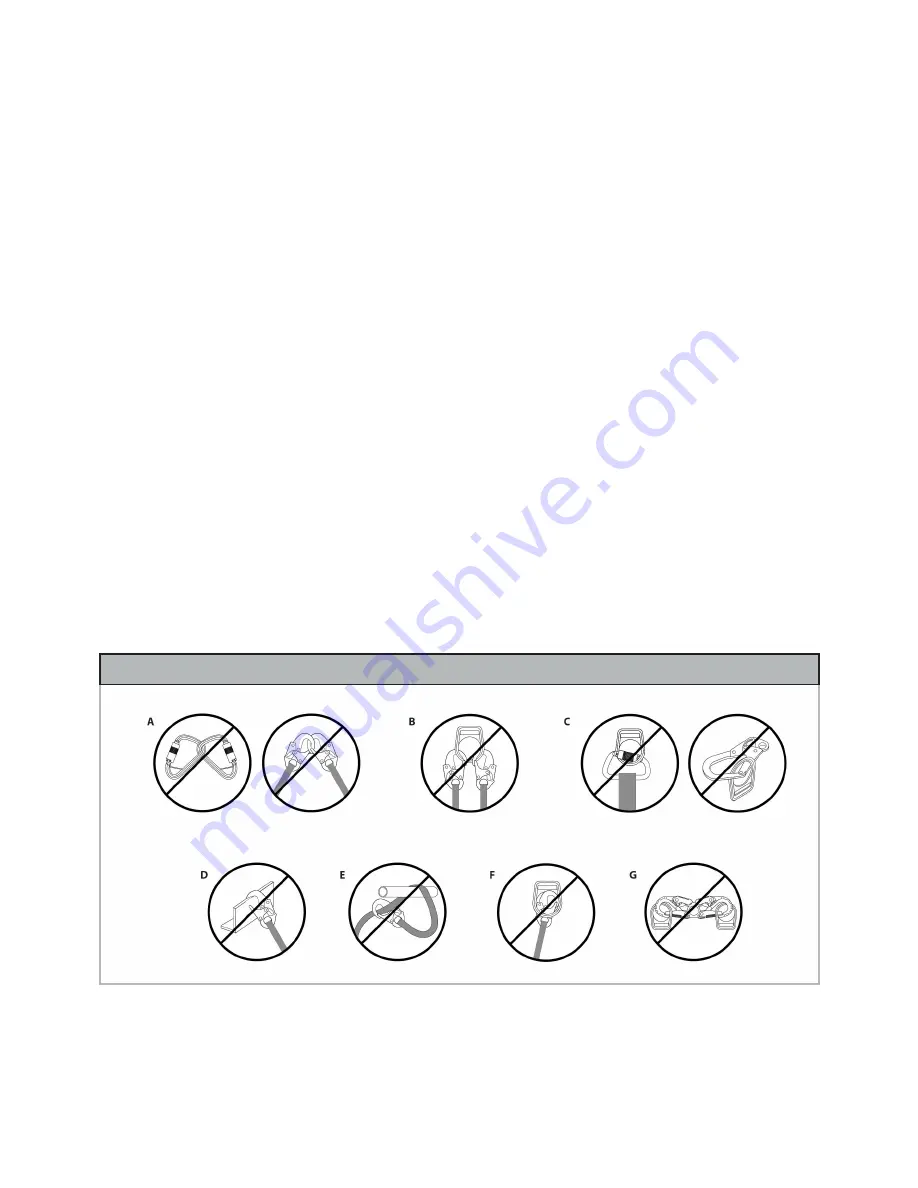

Compatibility of Connectors: Connectors are considered to be compatible with connecting elements when they have been designed to

work together in such a way that their sizes and shapes do not cause their gate mechanisms to inadvertently open regardless of how

they become oriented. Contact FallTech if you have any questions about compatibility. Connectors must be compatible

with the anchorage or other system components. Do not use equipment that is not compatible. Non-compatible connectors

may unintentionally disengage. Connectors must be compatible in size, shape, and strength. Self-closing, self-locking snap hooks

and carabiners are specified by OSHA and ANSI Z359.12.

3.2

Compatibility of Components: Equipment is designed for use with approved components and subsystems only. Substitutions or

replacements made with non-ANSI Z359 compliant components or subsystems may jeopardize compatibility of equipment and may affect

the safety and reliability of the complete system, see Figure 1. Ensure compatibility between the connectors if non-FallTech components

are used for fall protection.

3.3

Connectors: Only use self-locking snap hooks, rebar hooks, and carabiners with this equipment. Only use connectors that are suitable to

each application. Ensure all connections are compatible in size, shape and strength. Do not use equipment that is not compatible. Visually

ensure all connectors close and lock completely. Connectors (snap hooks, rebar hooks, and carabiners) are designed for use only

as specified in this manual.

Figure 1 - Non-Compatible Connections