15

ENGLISH

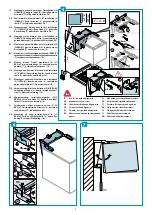

ELECTRICAL CONNECTION

(only intended for qualiied personnel)

Disconnect the equipment from electrical mains power supply before carry-

ing out any operations on the hood.

Ensure that the wires inside the hood are not disconnected or cut:

in the event of damage, contact your nearest Servicing Department.

Refer to qualiied personnel for electrical connections.

Connection must be carried out in compliance with the provisions of law in force.

Before connecting the hood to the electrical mains power supply, check that:

П voltage supply corresponds with what is reported on the data plate located inside the

hood;

П the electrical system is compliant and can withstand the load (see the technical specii

-

cations located inside the hood);

П the power supply plug and cable do not come into contact with temperatures exceed

-

ing 70 °C;

П the power supply system is efectively and properly connected to earth in compliance

with regulations in force;

П

the socket used to connect the hood is within reach.

In case of:

П devices itted with cables without a plug: the type of plug to use is a ''standardised'' one.

The wires must be connected as follows: yellow-green for earthing, blue for neutral and

brown for the phase. The plug must be connected to an adequate safety socket.

П

ixed equipment not provided with a power supply cable and plug, or any other device

that ensures disconnection from the electrical mains, with an opening gap of the con-

tacts that enables total disconnection in overvoltage category III conditions.

Said disconnection devices must be provided in the mains power supply in compliance

with installation regulations.

The yellow/green earth cable must not be cut of by the switch.

The Manufacturer declines all responsibility for failure to comply with the safety regulations.

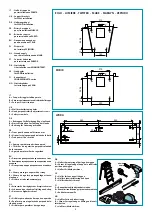

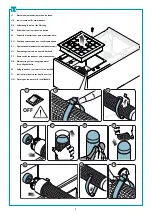

FUMES DISCHARGE

HOOD WITH INTERNAL RECIRCULATION (FILTERING)

In this version, air passes through zeolite-carbon ilters and the

E.ION ionising system to be puriied and recycled in the environ-

ment. Make sure the zeolite-carbon ilters are installed in the hood,

otherwise, apply them as indicated in the assembly instructions.

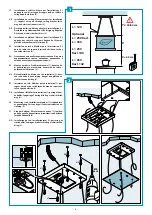

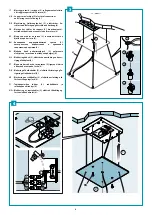

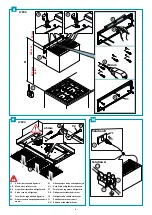

ASSEMBLY INSTRUCTIONS

only intended for personnel qualiied

The hood can be installed in various conigurations.

The generic assembly steps apply to all installations; for each case, follow

the speciic steps provided for the required installation.

OPERATION

WHEN TO TURN ON THE HOOD?

Switch on the hood at least one minute before starting to cook to direct fumes and vapours

towards the suction surface.

After cooking, leave the hood operating until complete extraction of all vapours and odours.

By means of the Timer function, it is possible to set auto switch-of function which will allow

the hood to turn of automatically after 15 minutes of operation.

AIR QUALITY

Air quality is displayed by the colour of the leaf.

Green

= excellent quality.

Yellow

= pollutant agents found.

The higher the number of pollutant agents, the darker the yellow

colour.

WHICH SPEED IS TO BE SELECTED?

1st speed:

maintains the circulation of clean air with low electricity consumption.

2nd speed:

normal conditions of use.

3rd speed:

presence of strong odours and vapours.

4th speed:

rapid disposal of odours and vapours.

(*)Note: 4th speed not included on SPRING and LYBRA models.

WHEN SHOULD THE FILTERS BE WASHED OR REPLACED?

The metal ilters must be cleaned every 30 hours of operation.

The zeolite-carbon ilters must be reactivated every 18 months and replaced every 3 years.

For further details see the

“MAINTENANCE”

chap.

TOUCH PUSHBUTTON PANEL

Motor ON/OFF

Upon start-up, the speed is that stored at the previous operation.

Increase speed from 1 to 4

Speed 4 is only active for a few min-

utes, then speed 3 activates.

NOTE: only 3 speeds for SPRING and

LYBRA

The speeds are indicated by the LEDs

on the keys:

Speed 1

Speed 2

Speed 3

Speed 4

("+" LED lashing)

Riduzione velocità da 4 a 1

Automatic cycle:

the hood only activates when pollutant agents are found.

The function deactivates if:

- no pollutant agents are found for 3 hours;

- The TIMER key (

) is pressed again.;

- keys + and - are pressed

Light on/of

TIMER

(

red LED lashing)

Auto switch-of after 15 min.

The function deactivates (red LED of ) if:

- The TIMER key (

) is pressed again.

- The ON/OFF key (

) is pressed.

FILTER ALARM

(Red LED on with (

) of)

Anti-grease ilter maintenance after approximately 30 hours of operation.

Press (

) for 3 seconds to reset.

MAINTENANCE

Before cleaning or carrying out maintenance operations, disconnect the

equipment by removing the plug or switching of the main switch.

Do not use detergents containing abrasive, acidic or corrosive substances

or abrasive cloths.

Regular maintenance guarantees proper operation and performance over time.

Special attention is to be paid to the

metal anti-grease ilters

: frequent cleaning of the

ilters and their supports ensures that no lammable grease is accumulated.

CLEANING OF EXTERNAL SURFACES

You are advised to clean the external surfaces of the hood

at least once every 15 days

to

prevent oily substances and grease from sticking to them.

Alternatively

and for all the other types of surfaces

, it can be cleaned using a damp cloth,

slightly moistened with mild, liquid detergent or denatured alcohol.

Finish of cleaning by rinsing well and drying with soft cloths.

Do not use too much water next to the push button control panel and

lighting devices in order to prevent humidity from reaching electronic

parts.

The glass panels can only be cleaned with speciic, non-corrosive or non-abrasive deter-

gents using a soft cloth.

The Manufacturer declines all responsibility for failure to comply with these instructions.

CLEANING OF INTERNAL SURFACES

It is forbidden to clean electrical parts, or parts related to the motor inside

the hood, with liquids or solvents.

For the internal metal parts, see the previous paragraph.

Summary of Contents for E.Ion Lumiere 67 White

Page 1: ...Falmec E Ion Lumiere 67 White...

Page 6: ......

Page 12: ......

Page 18: ......

Page 24: ......

Page 30: ......

Page 32: ...26 2 13 8 1 5 65 25 6 EN60335 2 31 11 07 2002 TC61 7 12 1 15 10 11...

Page 36: ......

Page 42: ......

Page 48: ......

Page 54: ......

Page 60: ......

Page 61: ...50 NOTE NOTES...

Page 62: ......

Page 64: ......