26

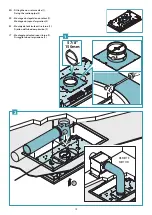

The outlet pipe must have:

• a diameter not less than that of the hood fitting.

• a slight slope downwards (drop) in the horizontal sections to prevent conden-

sation from flowing back into the motor.

• the minimum required number of bends.

• the minimum required length to avoid vibrations and reduce the suction per-

formance of the hood.

You are required to insulate the pipes if it passes through cold environments.

In the presence of motors with 500 CFM or higher, a check valve is present to

prevent external air flowing back.

HOOD WITH INTERNAL RECIRCULATION (FILTERING)

In this model, the air passes through an optional filter unit in

the ceiling to be purified and recycled in the environment.

In this version the check valve must not be assembled: remove it if it is

on the air outlet fitting of the motor.

ASSEMBLY INSTRUCTIONS

only intended for qualified personnel

The hood can be installed in various configurations.

The generic assembly steps apply to all installations; for each case,

follow the specific steps provided for the required installation.

OPERATION

WHEN TO TURN ON THE HOOD?

Switch on the hood at least one minute before starting to cook to direct fumes

and vapours towards the suction surface.

After cooking, leave the hood operating until complete extraction of all vapours

and odours. By means of the Timer function, it is possible to set auto switch-off

function which will allow the hood to turn off automatically after 15 minutes of

operation.

WHICH SPEED IS TO BE SELECTED?

1st speed:

maintains the circulation of clean air with low electricity consumption.

2nd speed:

normal conditions of use.

3rd speed:

presence of strong odours and vapours.

4th speed:

rapid disposal of odours and vapours.

WHEN SHOULD THE FILTERS BE WASHED OR REPLACED?

The metal filters must be cleaned every 30 hours of operation.

For further details see the

“MAINTENANCE”

chap.

ELECTRONIC PUSHBUTTON PANEL

Motor ON/OFF

Upon start-up, the speed is that stored at the previous operation.

I

ncrease speed from 1 to 4

Speed 4 is only active for a few

minutes, then speed 3 activates.

The speeds are indicated by the

LEDs on the keys:

Speed 1

Speed 2

Speed 3

Speed 4

("+" LED flashing)

Reduce speed from 4 to 1

Light on/off

TIMER

(red LED flashing)

Auto switch-off after 15 min.

The function deactivates (red LED off ) if:

- The TIMER key ( ) is pressed again.

- The ON/OFF key ( ) is pressed.

If the pushbutton panel is completely inactive, before contacting

the Technical assistance service, disconnect power temporarily to

the appliance (about 5“), possibly by acting on the main switch, to

restore normal operation.

If this measure has no effect, contact the Technical assistance service.

USING THE RADIO CONTROL

WARNINGS!:

Place the hood away from sources of electromagnetic waves (e.g.

microwave ovens), which could interfere with the radio control and

with the hood electronics. The maximum operating distance is 5 metres,

that may vary according to the presence of electromagnetic interferences.

Radio control operated at 433.92MHz.

The radio control consists of two parts:

- the receiver built into the hood;

- the transmitter shown here in the figure.

DESCRIPTION OF TRANSMITTING COMMANDS

UP

Motor switch-on and speed increase

from 1 to 4. Speed 4 is only active for a

few minutes.

DOWN

Speed decrease and motor switch-off.

Light ON-OFF

TIMER ON:

The motor automatically

switches off after 15 min.

The function is automatically disabled if

the motor is switched off (

key)

Command transmission active

RADIO CONTROL CODE CHANGE

With only one radio control, go directly to point 2.

With several radio controls in the same room, a new code can be created by

following the procedure below.

Disconnect the power to the hood before starting the procedure.