ENGLISH

43

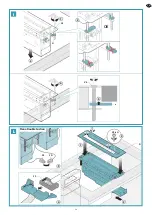

Phase

B2

on page

To be able to install the optional "Piano under furniture carbon-zeo ilter (

KF

)” kit and to be

able to perform the subsequent maintenance operations, a minimum available space of

1100mm is required, including the motor unit clearance (

UM

) and the optional "Piano under

furniture carbon-zeo ilter (

KF

)” kit. In relation to the dimensions of the furniture, to the type

of installation of the cooking area (wall or island) and to the required air output direction, it is

possible that the air output itting of the motor unit (

UM

) is partly aligned with the furniture

legs and it is therefore necessary to move some.

Make sure that this operation does not compromise stability of the fur-

niture.

To avoid this problem or to position the optional "Piano under furniture carbon-zeo

ilter

(KF)" kit in a position which allows easier maintenance, the optional “Double

horizontal curve (KDC

)

” kit is available, whose dimensions are shown in the technical

speciications on page 9

on page

To install the iltering version hood one or more suitably sizes holes must

be drilled in the kitchen plinth (

Fig.

1

), to allow puriied air to exit the

under furniture compartment.

For this reason two air grilles (

GA

) are supplied together with the optional "Piano under

furniture carbon-zeo ilter (

KF

) kit.

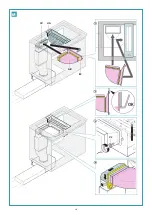

REMOTE MOTOR UNIT (URS OR URE)

The hood can be connected to the under-roof (

URS

) and outdoor (

URE

)

remote motor unit .

In the case of an under-roof motor unit (

URS

), it must be placed next to

the technical compartment inside the home, protected against atmos-

pheric agents and within reach for any maintenance operations.

In the case of an outdoor motor unit (

URE

), it is recommended to ind a

position protected from rain, snow, wind, etc., in order to prevent rain and

humidity from entering, which can damage the outdoor unit.

To connect the hood with an under-roof (URS) or outdoor (URE) remote

unit a conveyor kit must always be installed: read chapter “

” on page

to choose the most suitable conveyor

kit.

The dimensions of any drawers or baskets can be taken into account for this type of instal-

lation so as to assess which conveyor to assemble, as there is no under furniture motor unit.

on page

Prepare the suction pipe (

FR

) for connection of the hood to the under-roof (

URS

) or out-

door (

URE

) remote unit: preferably use pipes with rectangular sections of suitable sizes and

install them as an end part to be connected to the "Rectangular circular curve (

KACL.371

)"

conveyor kit (sold separately). Position the piping with reference to the furniture on the basis

of the heights (X and Y) indicated on the irst pages of this booklet, by using the centre of

the circular itting of the

KACL.371

part as a reference. Prepare a piece of pipe with circular

section (

F

) to allow subsequent assembly of the conveyor kit.

To install the hood with remote motor unit, the type of suction pipes used

and their position can vary considerably: in some cases it may not be nec-

essary to drill a hole on the bottom of the furniture having the sizes indi-

cated on the speciications “

SPECIFICATIONS AND SET-UP FOR WALL UNIT

To assemble the under-roof (

URS

) or outdoor (

URE

) remote motor unit, refer to the

relative instructions booklet.

Once the under furniture motor unit has been positioned or connection of the

suction pipe for the remote motor unit has been prepared, the assembly instructions of the

conveyor and the hood are generic, the diference being only whether there is a Piano Single

Suction hood or a Piano Double Suction hood.

To correctly install the hood the rectangular connection pipes, cut to the

right length, between the various ittings must be prepared: refer to the

technical speciications inserted in the irst pages of this booklet and to the

speciications

“Set-up for installation: examples of installation”

shown

from page

to page

on page

Assemble on the ground the set consisting of the conveyor kit (

KC

), the silencer (

ES

), the

vertical pipe (

T3

) and the curve (

CV

).

Insert the silencer (

ES

) directly in the conveyor kit (

KC

)(Fig.

1

); block the two parts using

the self-threading screws (

V1

) supplied (Fig.

2

).

Insert the vertical pipe (

T3

) in the silencer: there are metal hooks inside it which ensure

correct positioning (Fig.

3

).

Lastly, assemble the curve (

CV

) on the vertical pipe (

T3

).

Afterwards seal all joints with adhesive tape (supplied) to prevent any accumulation of con-

densation from seeping through the coupling joints of the various parts (Fig.

4

and

5

).

URS

URE

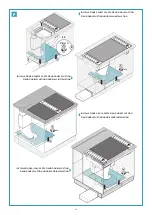

Carefully place the assembled set (

AC

) in the furniture by inserting the circular itting of the

conveyor kit in the circular itting of the under furniture motor unit or in the circular pipe (for

connection with remote motor unit) prepared previously (Fig.

1

); also seal this joint with the

adhesive tape supplied (Fig.

2

).

Next, prepare the set consisting of the horizontal pipe (

T2

), the curve (

CO

), eventual pipe

(

T1

) present only in some types of installation, and the conveyor part (

EC

).

To insert the conveyor part (EC), do not remove the protective ilm of the

seal ring (Fig.

2

).

Seal all joints with adhesive tape (supplied) to prevent any accumulation of con-

densation from seeping through the coupling joints of the various parts (Fig.

3

).

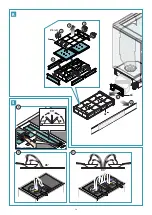

Remove the part with the adjustable laps (

EV

) from the suction unit (

UA

): proceed with

caution, taking care to irst lift the front and then removing the two pins in the rear part

(Fig.

2

).

Remove the metal anti-grease ilter (

A

), the drilled part (

B

) and the grease drip tray (

C

) (Fig.

3

).

Disconnect the push button control panel connector (

CP

) as shown in (Fig.

4

) (for the

Piano Double Suction hood, only for the suction unit equipped with push button control

panel).

Remove the stainless steel frame (

D

) assembled on the suction unit by turning the 4 screws

(

V2

) (Fig.

5

).

Before inserting the hood in the worktop, for some types of installation it is necessary to

remove the knockouts (

E

) on the suction unit (Fig.

6

); these parts are necessary to prevent

the liquid from leaking from the cooker top inside the furniture and as a support part of the

top itself, but are to be removed from the side supporting the worktop and in the event of

cooker tops with unsuitable dimensions.

The knockouts must always be removed after having irst removed the

stainless steel frame.

on page

Turn the screws (

V3

) (Fig.

1

) to position the ixing elements (

G

) of the suction unit in the

position shown in (Fig.

2

) to allow the hood to be inserted in the hole drilled in the work-

top (Fig.

3

).

Tighten all screws (

V3

)(Fig.

4

) to lift the ixing elements (

G

) and block the hood on the

worktop (Fig.

5

).

on page

Reassemble the stainless steel frame (

D

) (Fig.

1

) using the screws (

V2

) removed previously

(Fig.

2

) and reposition the grease drip tray (Fig.

3

).

Reconnect the push button control panel connector (

CP

) (Fig.

4

).

Only for Piano Double Suction hood version

Connect the connector (CS) from the suction unit not provided with controls to the

corresponding connector (CD) positioned in the suction unit with push button con-

trol panel (Fig.

5

).

If this operation is not carried out, operation of the hood motor is prevent-

ed.

on page

Install the previously assembled set (

AB

), simultaneously coupling it in the suction unit (

UA

)

and the curve (

CV

) (Fig.

1

): make sure the fold on the rear of the conveyor part (

EC

) its into

the hole on the suction unit (

UA

)(Fig.

2

).

Lock the set (

AB

) to the suction unit (

UA

) with the screws (

V2

) supplied (Fig.

3

) and seal

the joint made with the curve (

CV

) with the adhesive tape supplied (Fig.

4

) .

on page

Reposition the drilled part (

B

) and the metal anti-grease ilter (

A

) (Fig.

1

and

2

).

Reassemble the part with the adjustable laps (

EV

) (Fig.

3

and

4

): proceed with caution,

taking care to correctly insert the two pins in the rear part in the corresponding holes on the

stainless steel frame of the suction unit.

Connect the hood connector (

CC

) to the connector (

CM

) on the under furniture extractor

fan or coming from the remote motor unit (Fig.

1

).

The electrical junctions and the connection couplings must not be accessi-

ble after installation.

Electrically power the hood in accordance with regulations in force.

The hood is supplied with a safety device which prevents operation of the

motor should the adjustable laps of the suction unit be in the closed posi-

tion.

Cover the hole on the bottom of the furniture with the langes (

FF

) supplied: secure them

using the appropriate screws (

V4

) following the indications relative to the type of installation

carried out.

Summary of Contents for piano

Page 24: ...24 A1 217mm 87mm UM X F 1 3 Y 2 A2 KDC F UM UM...

Page 28: ...28 3 2 1 EV A UA B D C V2 x4 5 CP OK OK Crack E 4 6 H...

Page 29: ...29 1 3 V3 G 4 5 V3 G 2 OK D CP 5 4 1 3 V2 x4 CS CD 2 Piano Double Suction I L...

Page 30: ...30 M 2 OK 1 3 AB UA V2 EC CV 4...

Page 31: ...31 3 EV 4 1 2 B A CM CC 1 2 N O...

Page 33: ...33 Q 4 5 6 3 2 1 EV A UA B C B...

Page 34: ...34 1 2 3 4 5 6 FK AF A V5 x5 R S 3 2 45 90 45 90 45 1...