27

ENGLISH

SAFETY INSTRUCTIONS AND WARNINGS

INSTALLATION WARNINGS

TECHNICAL SAFETY

Installation operations are to be carried out by skilled and qualiied install-

ers in accordance with the instructions in this booklet and in compliance

with the regulations in force.

•

Before installing the hood, check the integrity and function of each part. Should

anomalies be noted, do not proceed with installation and contact the Dealer.

•

Do NOT install the hood if an aesthetic defect has been detected. Put it back into

its original package and contact the dealer. No claim can be made for aesthetic

defects once the hood has been installed.

•

During installation, always use personal protective equipment (e.g. accident-prevention

shoes) and adopt prudent and proper conduct.

•

The components of the ixing kit (supplied with the hood) required to ix the

safety chains are only to be used on masonry walls: should it be necessary to use

them on walls of diferent material, assess other ixing systems, keeping the wall's

strength and the weight of the hood in mind

(indicated in the technical speciications

inserted in the irst part of this booklet).

•

Keep in mind that installations with diferent types of ixing systems from those supplied,

or which are not compliant, can cause electrical and mechanical seal danger.

•

Do not modify the electrical, mechanical and functional structure of the equipment.

•

Do the install the hood outdoors and do not expose it to atmospheric agents (rain, wind,

etc.)

•

After the stainless steel hood has been installed, it will need to be cleaned to remove any

residues from the protection adhesive as well as any grease and oil stains which, if not

removed, can cause irreversible damage to the hood surface. To do so the manufacturer

recommends using the supplied moist wipes, which are also available sold separately.

ELECTRICAL SAFETY

The electrical system to which the hood is to be connected must be accord-

ing to standard and compulsorily supplied with earthed connection in

compliance with safety regulations in the country of use. It must also com-

ply with European standards regarding radio antistatic properties.

•

Before installing the hood, check that the electrical mains power supply corresponds

with what is reported on the identiication plate located inside the hood.

•

The socket used to connect the installed equipment to the electrical power supply must

be within reach: if this is not possible, install a mains switch in an accessible position in

order to disconnect the hood when required.

•

Any changes to the electrical system required to install the hood must be carried out by

a qualiied electrician.

•

It is dangerous to change, or try to change, the features of this equipment. Do not try

to solve the problem yourself in the event of equipment malfunction, but contact the

Dealer or an authorised Servicing Department for repairs.

•

When installing the hood, disconnect the equipment by removing the plug or

switching of the main switch.

FUMES DISCHARGE SAFETY

•

Do not connect the equipment to discharge pipes of fumes produced from com-

bustion (for example boilers, ireplaces, etc.)

•

Before installing the hood, ensure that all standards in force regarding discharge of air out

of the room have been complied with.

USER WARNINGS

GENERAL WARNINGS

These warnings have been drawn up for your personal safety and those of

others. You are therefore kindly asked to read the booklet carefully in its

entirety before installing and using the equipment or carrying out clean-

ing operations.

•

The Manufacturer declines all responsibility for any damage caused directly, or

indirectly, to persons, things and pets as a consequence of failing to comply with

the safety warnings indicated in this booklet.

•

It is imperative that this instructions booklet is kept together with the equipment

for any future consultation. If the equipment is sold or transferred to another per-

son, make sure that the booklet is also supplied so that the new user can be made

aware of the hood's operation and relative warnings.

•

Installation operations are to be carried out by a skilled and qualiied installer in

accordance with the instructions in this booklet and in compliance with the reg-

ulations in force.

•

DO NOT use the hood if the power supply cable or other components are dam-

aged.

Disconnect the hood from the electrical power supply and contact the Dealer

or an authorised Servicing Department for repairs. Insist on original spare parts.

Do not

personally try to carry out repairs or replacements. Interventions carried out by in-

competent and unauthorised persons can cause damage, even serious, to things

and/or persons not covered by the Manufacturer's warranty.

•

Do not modify the electrical, mechanical and functional structure of the equipment. Any

changes to the electrical system required to install the hood must be carried out by a

qualiied electrician.

INTENDED USE

•

The equipment is solely intended to be used to extract fumes generated from

cooking food in non-professional domestic kitchens

: any other use is improper, can

cause damage to persons, things and pets and exempts the Manufacturer from any li-

ability.

•

The equipment can be used by children above the age of 8 and by persons with reduced

physical, sensory and mental abilities, or with no experience or knowledge, as long as

they do so under supervision or after having received relative instructions regarding safe

use of the equipment and understanding of the dangers connected to it. Children are

not to play with the equipment. Cleaning and maintenance operations intended for the

user must not be carried out by children without supervision.

•

USE AND CLEANING WARNINGS

•

Before cleaning or carrying out maintenance operations, disconnect the equip-

ment by removing the plug or switching of the main switch.

•

Do not use the hood with wet hands or bare feet.

•

Always check that all electrical parts (lights, extractor fan) are of when the equipment

is not used.

•

Check the deep-fryers during use: Overheated oil can catch ire.

•

Do not light naked lames under the hood.

•

Do not lambé foods under the hood.

•

Never use the hood without the metal anti-grease ilters: in this case, grease and dirt will

deposit in the equipment and compromise its operation.

•

Accessible parts of the hood can be hot if used together with cooking appliances.

•

Do not carry out any cleaning operations when parts of the hood are still hot.

•

There can be a risk of ire if cleaning is not carried out according to the methods and

products indicated in this booklet.

•

Disconnect the main switch when the equipment is not used for long periods of time.

If other appliances that use gas or other fuels are being used at the same time

(boiler, stove, ireplaces, etc.), make sure the room where the fumes are extracted

is well-ventilated, in compliance with the current regulations.

WARNINGS IN CASE OF MALFUNCTION

•

DO NOT use the hood if the power supply cable or other components are dam-

aged.

Disconnect the hood from the electrical power supply and contact the Dealer

or an authorised Servicing Department for repairs. Insist on original spare parts.

Do not

personally try to carry out repairs or replacements. Interventions carried out by in-

competent and unauthorised persons can cause damage, even serious, to things

and/or persons not covered by the Manufacturer's warranty.

The Manufacturer reserves the right to make changes to the equipment at any time and

without prior notice. Printing, translation and reproduction, even partial, of this manual are

bound by the Manufacturer's authorisation.

Technical information, graphic representations and speciications in this manual are for infor-

mation purposes and cannot be divulged.

This manual is written in Italian. The Manufacturer is not responsible for any transcription or

translation errors.

INSTALLATION

(only intended for personnel qualiied to install the hood)

Before installing the hood, carefully read Chap. "Safety instructions and

warnings" on page 27.

TECHNICAL FEATURES

The technical speciications are reported on the identiication plate located inside the hood.

POSITIONING

The recommended distance between the highest part of the cooker and the lowest part of

the hood is approximately 110 cm (43.3").

In certain cases, this distance can be increased up to a maximum of approximately 150 cm

(59"), with a slight decrease in the eiciency of the device.

The minimum installation distance must not be less than 65 cm (25.5"), as provided by the

standard, also according to an interpretation of standard EN60335-2-31 dated 11-07-2002 by

TC61 (sub-clause 7.12.1 meeting 15 agenda item 10.11).

Should the instructions for the gas cooker specify a greater distance, take this into consid-

eration.

Do not install the hood outdoors and do not expose it to atmospheric agents (rain, wind,

etc.)

ELECTRICAL CONNECTION

(only intended for personnel qualiied to install the hood)

Disconnect the equipment from electrical mains power supply before car-

rying out any operations on the hood.

Make sure that the wires inside the hood are not disconnected or cut.

Should this occur, contact your nearest Servicing Department. Refer to

qualiied personnel for electrical connections.

Connection must be carried out in compliance with the provisions of law in force.

Summary of Contents for stella

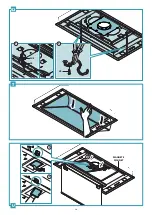

Page 7: ...7 800 m3 h 950 m3 h 9 mm...

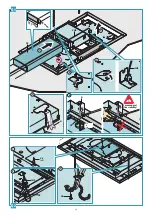

Page 9: ...9 X Y X 1 2 Y 4 3 9 mm C...

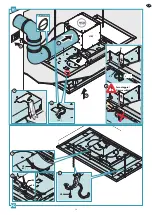

Page 16: ...16 3 V4 1 V5 x4 V6 x4 CM CE 2 N2...

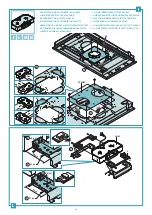

Page 20: ...20 CUE CE 1 V4 2 S2 T MAGNETE MAGNET 3 1 2 U...

Page 47: ...47 8 47 110 43 3 150 59 65 25 5 EN60335 2 31 11 07 2002 TC61 7 12 1 15 10 11...

Page 50: ...50 15 30 51 Stella 4 5 433 92 1 2 1 4 5 5 2 2 10 5 2 ON OFF 1 1 2 3 4 4 7 3 1 1 2 3 4 1 15...

Page 51: ...51 15 1 2 3 4 4 7 3 1 2 3 15 Magic Steel 1 55 C T 20 U 20 RAEE RAEE...

Page 87: ...NOTE NOTES...