6.0 Maintenance

Your Famag spiral mixer is a serious kitchen machine that will produce exceptional dough in large quantities for years—and

likely for decades—with proper care. As with any such equipment, parts of your mixer need periodic inspection and

maintenance, and wear parts will eventually require replacement.

Some details are provided in this document, but it is essential to note that this document is only one part of your user

manual. The other part consists of instructional videos and other resources available only in the PHG Famag Use Video

Library on the Pleasant Hill Grain website. Those website resources are CRUCIAL for proper maintenance of your

investment. Following the directions in this part of the manual and in the videos will ensure that the user-maintenance

requirement of your Famag warranty is met.

The two most important aspects of your mixer that require regular inspection (and adjustment as needed) are the drive belts

in the base of the mixer, and the drive chain in the head of the mixer. The drive belts must be kept in proper tension. The

drive chain must be kept lubricated, and the dough hook sprocket must be adjusted to take up slack caused by natural

elongation of the chain, due to wear.

In addition to scheduled inspections, the drive belts and chain must be inspected immediately if the bowl or dough hook stop

turning or turn slower than usual, or at erratic speeds, or if unusual sounds come from the head of the machine. New sounds

that develop gradually might escape notice, but any kind of rattling, knocking, clattering or slapping sounds coming from the

head of the machine would mean a loose chain and require immediate inspection and adjustment.

Videos in the PHG Famag Use Video Library provide detailed, step-by-step instructions for each part of your machine,

including important techniques, tool recommendations, and key specifications for belt tensioning and chain replacement. We

recommend viewing all of the videos in the Library in your first week of Famag ownership. They’re packed with information

that will maximize your Famag experience and keep your mixer humming along in peak form for many years!

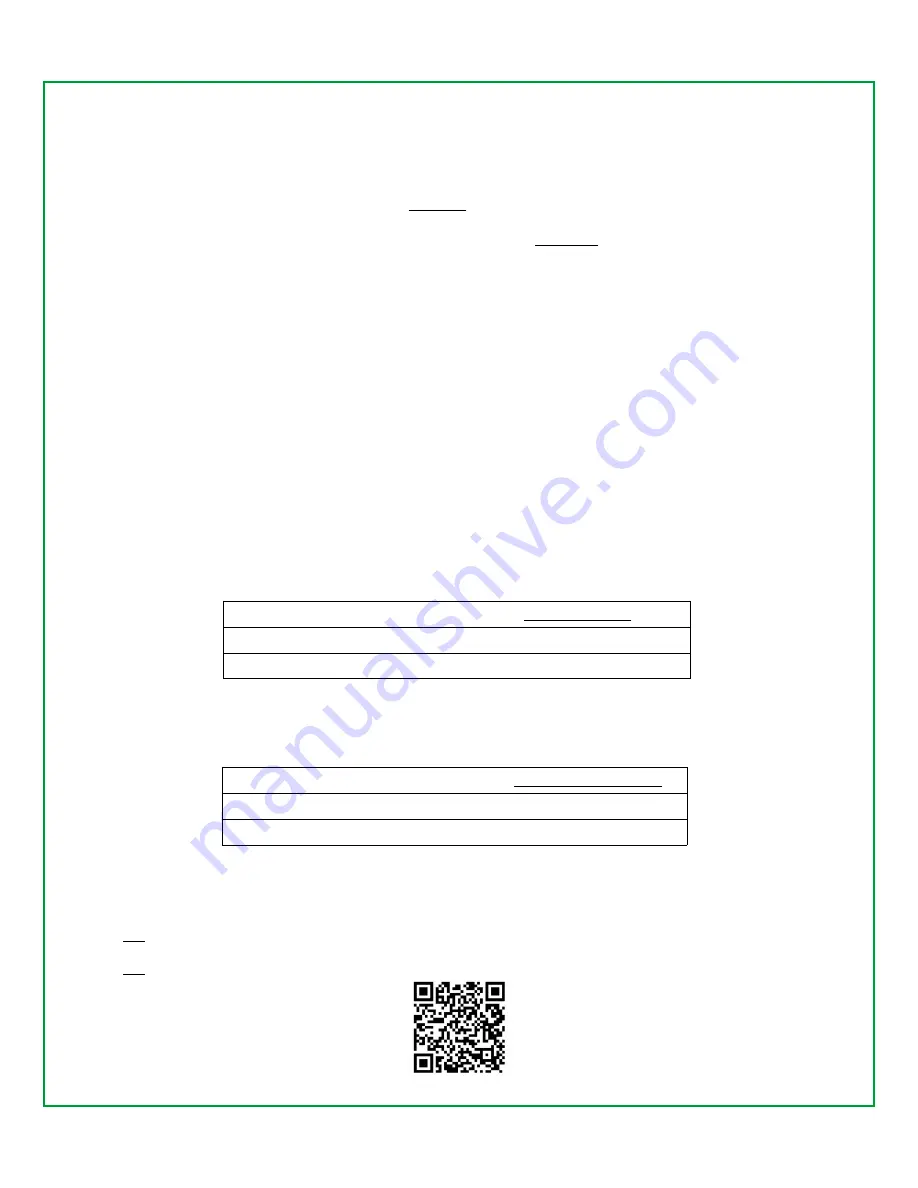

These service intervals apply to Famag mixers used domestically or commercially, respectively:

Belt and Chain Inspection Intervals for Home Users

First inspection at 6 months

Continuing inspections every 6-12 months depending on usage

Note: “Home Use” infers typical domestic usage. For higher-volume usage performed

in a home kitchen, you must follow the intervals for “Commercial Users”, below.

Belt and Chain Inspection Intervals for Commercial Users

First inspection at 45 days

Continuing inspections at least every 4 months

Following are three different ways to access the Famag Use Video Library:

1:

Enter the web address into your web browser:

4phg.com/famag-mixer-video-library

2.

OR

go to the footer of most any page on the PHG website, and under “Help & Info”, Click “Resources”, then scroll

down to the “Product-Use Libraries” section, and click “Videos for Famag IM-5/8/10 Mixers”.

3.

OR

scan this QR code:

6