Chapter 4 Electrical Installation

Shenzhen Hpmont Technology Co., Ltd.

- 18 -

HD3N-L Series User Manual V1.0

4.6.2

Wiring Requirement

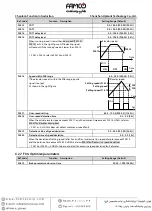

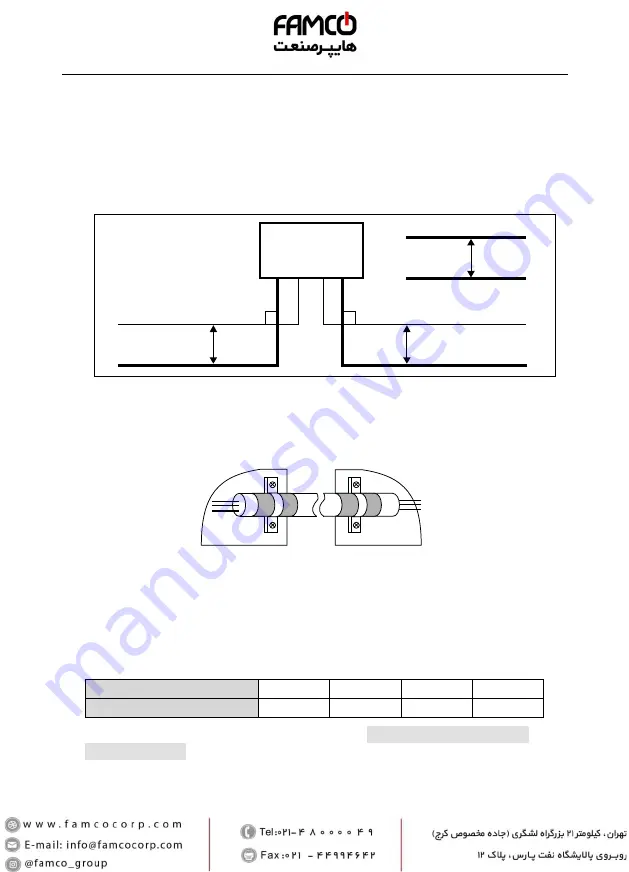

In order to avoid interference intercoupling, it is recommended to separate the power supply cables,

motor cables and the control cables, and keep enough distance among them, especially when the

cables are laid in parallel and are long enough.

The signal cables should cross the power supply cables or motor cables, keep it perpendicular (90

°

) as

shown in Figure 4-5.

Distribute the power supply cables, motor cables and control cables in different pipelines.

Figure 4-5 System wiring

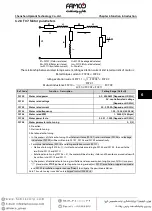

Shielded or armoured cable: High frequency low impedance shielded cable should be used. For

example: Copper net, aluminum net or iron net.

Normally, the control cables must use the shielded cables and the shielding metal net must be

connected to the metal enclosure of the controller by cable clamps as shown in Figure 4-6.

Figure 4-6 Shielded cable connection

4.6.3

Motor Connection

The longer motor cable is, the higher carrier frequency will be, causing the high harmonic leakage

current on the cable to increase as well. This may affect peripheral devices.

When the motor cable length is longer than 100 meters, it is recommended to install AC output reactor

and adjust the carrier frequency according to Table 4-5.

Table 4-5 Carrier frequency and the cable length betweencontroller and motor

Cable Length

<30m

30 - 50m

50 - 100m

≥100m

Carrier Frequency

Below 15kHz

Below 10kHz

Below 5kHz

Below 2kHz

The cross sectional area (CSA) of motor cable should refer to section 4.2 Peripheral Accessories

Selection, on page 11.

The controller should be derated if motor cables are too long or their CSA is too large. The current

should be decreased by 5% when per level of CSA is increased. so do the leakage current to ground

and capacitance.

Controller

Power supply cable

Power supply cable

Motor cable

Motor cable

Control cable

Control cable

90°

>20 cm

90°

>50 cm

>30 cm

PE

PE

Enclosure

Enclosure