6

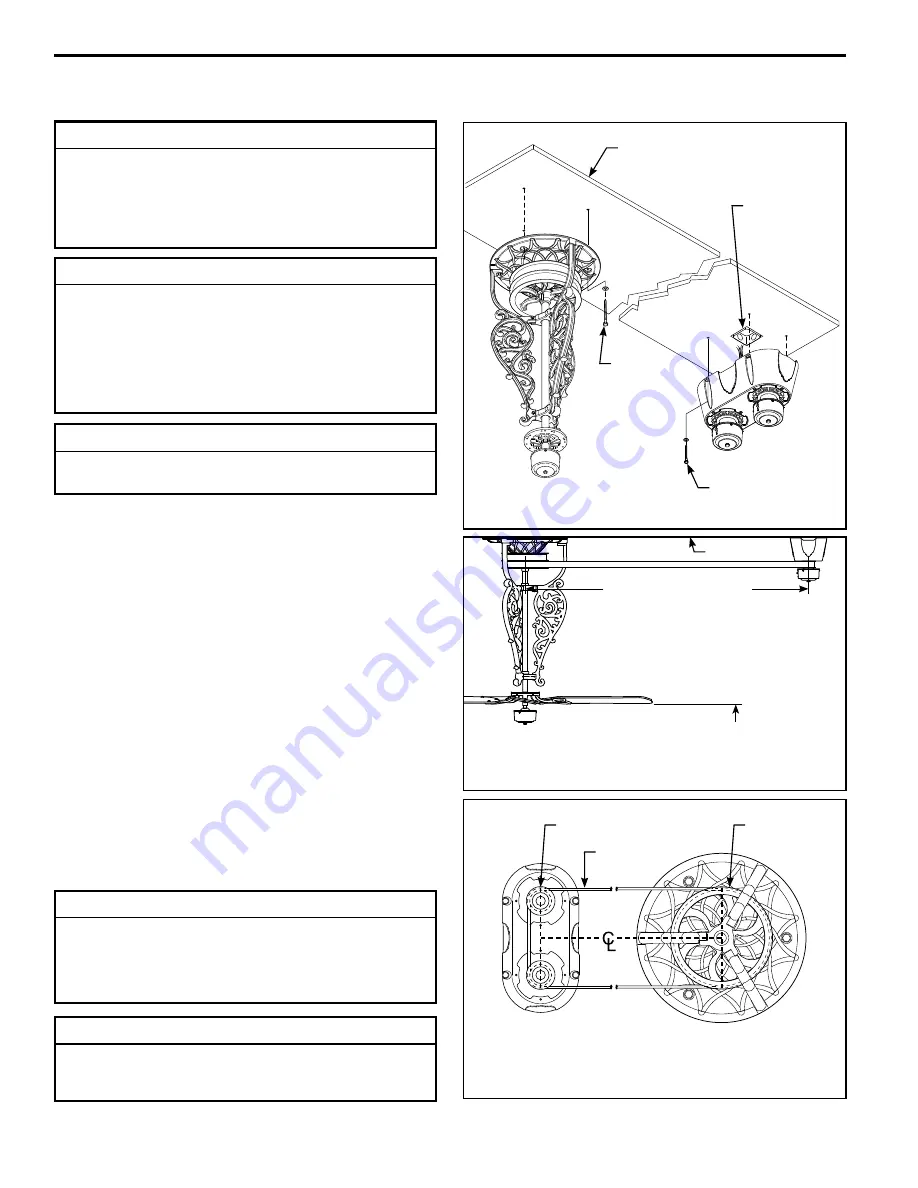

How to Hang and Wire Your Ceiling Fan

Mounting Motor Unit:

1.

Mark mounting hole positions for the motor unit onto

the ceiling or supporting member.

2.

Drill

1

⁄

8

˝

pilot holes into the plywood base or supporting

member to prevent splitting or cracking. While supporting

the Motor Assembly, screw the lag bolts (¼

˝

x 2

˝

)

approximately “half-way” in. This will allow enough space

between the ceiling panel and motor base to properly

wire your motor.

3.

Connect the green grounding lead from the fan motor

to the supply grounding conductor (this may be a bare

wire or wire with green colored insulation). Securely

connect wires with wire connectors supplied. (Figure 4)

NOTE:

Motor assembly

must

be perpendicular to the

direction of belting running from the motor to the first fan.

Drive belt

must

wrap around both motor pulleys. Be sure

to position the fan pulley so that the belt won’t rub against

the support legs.

(Figure 3)

Be sure of your belt-layout

plans before installing both the motor and fan assemblies.

Ceiling

No

less than

7 ft from

fl

oor

Figure 1

2

˝

Lag Bolt

& Flat Washer

(4 places)

3

˝

Lag Bolt

& Flat Washer

(3 places)

Outlet Box Flush

to Finished

Ceiling

Plywood (¾

˝

thick min.)

Backing Secured to

Structural Member

Figure 2

16 ft max - motor to head

6 ft min

(16 ft max - head to head)

Figure 3

Motor Pulley (2)

Fan Pulley

Belt

NOTE:

Switch housing caps and flywheel assemblies

removed for belt detail clarity

CAUTION

Do not connect fan blades until the fan is completely

installed. Hanging fan with blades connected may result

in damage to the fan blades.

▲

WARNING

Do not install or use fan if any part is damaged or

missing. This product is designed to use only those

parts supplied with this product and/or any accessories

designated specifically for use with this product by

Fanimation. Substitution of parts or accessories not

designated for use with this product by Fanimation could

result in personal injury or property damage. Contact

your retail store for missing or damaged parts.

INSTALLATION NOTE

HEAVY! Two or three people are required to hang the

motor and fan / pulley assemblies.

INSTALLATION NOTE

The fan must be hung with at least 7’ of clearance

from floor to blade. The maximum overall distance

between motor & pulley is 16´ and the minimum is 6´.

The maximum overall distance between two fan/pulley

assemblies is 16´ and the minimum is 6´.

(Figure 2)

INSTALLATION NOTE

It is recommended that each fan and the motor have ¾

˝

plywood backing secured to a structural member for

adequate support (Figure 1). A 120 VAC electrical feed,

centered under the motor unit and wired to a standard

wall switch (user supplied) is required. The motor unit

will not operate more than 6 fan assemblies or idlers.