1.

Check to see that you have received the following parts:

NOTE:

If you are uncertain of part description, refer to

exploded view illustration.

This Manual Is Designed to Make it as Easy as Possible for You to Assemble,

Install, Operate and Maintain Your Ceiling Fan

Tools Needed for Assembly

•

One Phillips head screwdriver

•

One stepladder

•

Three wire connectors (supplied)

3

Installed Wire Length

Up to 50 ft.

14

12

50-100 ft.

Wire Size A.W.G.

Unpacking Instructions

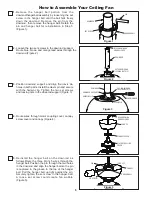

For your convenience, check-off boxes are provided next to each step. As each step is completed, place a check

mark in the box. This will insure that all steps have been completed and will be helpful in finding your place should

you be interrupted.

Before assembling your ceiling fan, refer to section

on proper method of wiring your fan (page 4). If you

feel you do not have enough wiring knowledge or

experience, have your fan installed by a licensed

electrician.

Do not install or use fan if any part is damaged or

missing. This product is designed to use only those

parts supplied with this product and/or any

accessories designated specifically for use with this

product by Fanimation. Substitution of parts or

accessories not designated for use with this product

by Fanimation could result in personal injury or

property damage.

WARNING

!

WARNING

!

•

One wire stripper

•

One 1/4” blade

screwdriver

Materials

Wiring outlet box and box connectors must be of type

required by the local code. The minimum wire would be a

3-conductor (2-wire with ground) of the following size:

NOTE:

Place the parts from the loose parts bags in a small

container to keep them from being lost. If any parts are

missing contact your local retailer.

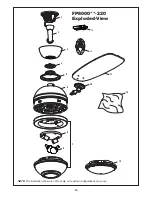

• Fan Motor Assembly

• Hanger Bracket Assembly with

screws

• Downrod/Hanger Ball Assembly

• Ceiling Canopy

• Canopy Screw Cover Assembly

• Motor Coupling Cover Assembly

• Blade Arm Set

• Blade Set

• Housing Light Kit Assembly

• Socket Plate Assembly

• Two 60W G-50 Light Bulbs

• Lower Steel Cap Assembly

• Glass

• Hardware bags:

–

3/16-24 x 7.5mm

(blade to blade holder)

Washer Head Screw

–

3/16” Fiber Washer

(blade to blade holder)

– 1/4”-20 x 14mm

(blade arm to motor)

Pan Head Screw

– Phillips Screwdriver, 4”

–

Four Wire Connectors

–

Balance Kit

HOUSING

LIGHT KIT

ASSEMBLY

LOWER

STEEL CAP

ASSEMBLY

HARDWARE BAG

HANGER

BRACKET

ASSEMBLY

W/SCREWS

DOWNROD/

HANGER BALL

ASSEMBLY

CANOPY

SCREW

COVER

ASSEMBLY

MOTOR

COUPLING

COVER

FAN MOTOR

ASSEMBLY

CEILING

CANOPY

TWO 60-WATT

G-50

LIGHT BULBS

SOCKET

PLATE

ASSEMBLY

GLASS

BLADE SET

BLADE ARM SET

• TR4WH-220V Remote Control

• Receiver Unit

TR4WH-220

REMOTE

CONTROL

RECEIVER

UNIT

Summary of Contents for FP8000-220 The Akira

Page 15: ......