14

Trouble Shooting

▲

WARNING

For your own safety turn off power at fuse box or circuit breaker before trouble shooting your fan.

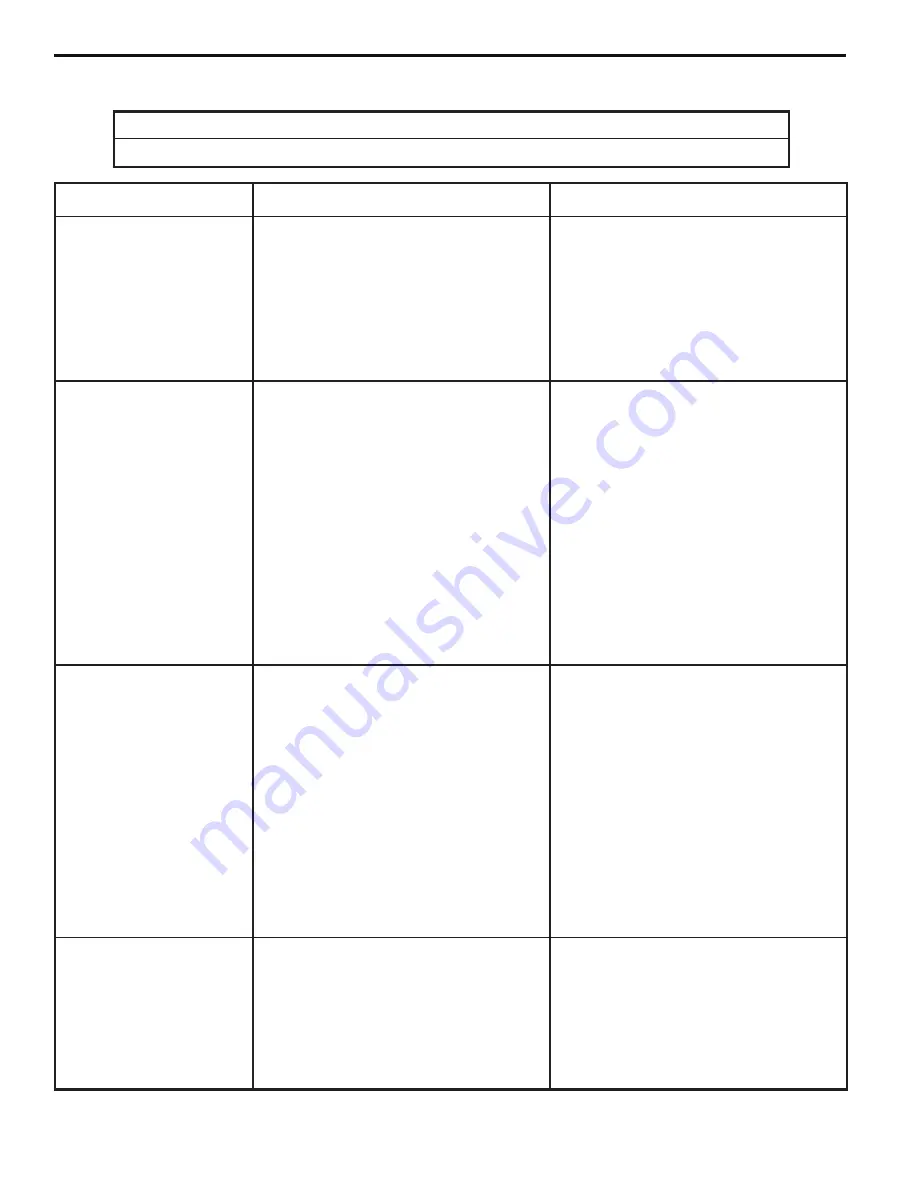

Trouble

Probable Cause

Suggested Remedy

1. FAN WILL NOT START

1.

Fuse or circuit breaker blown.

2.

Loose power line connections to the fan, or loose

switch wire connections in the switch housing.

3.

Reversing switch in neutral position.

4.

Dead battery in remote control.

1.

Check main and branch circuit fuses or circuit

breakers.

2.

Check line wire connections to fan and switch wire

connections in the switch housings.

CAUTION: Make sure main power is turned off !

3.

Make sure reversing switch position is all the way to

one side.

4.

Replace with fresh battery.

2. FAN SOUNDS NOISY

1.

Blades not attached to fan.

2.

Loose screws in motor housing.

3.

Screws securing fan blade holders to motor flywheel

are loose.

4.

Wire connectors inside housing rattling.

5.

Motor noise caused by solid state variable speed

control.

6.

Screws holding blades to blade holders are loose.

7.

Rubber flywheel set screw loose.

1.

Attach blades to fan before operating.

2.

Check to make sure all screws in motor housing are

snug (not over-tight).

3.

Check to make sure the screws which attach the fan

blade holders to the motor flywheel are tight.

4.

Check to make sure wire connectors in switch

housing are not rattling against each other or against

the interior wall of the switch housing.

CAUTION: Make sure main power is turned off !

5.

Some fan motors are sensitive to signals from

solid-state variable speed controls. Solid-state controls

are not recommended, choose an alternative control

method.

6.

Tighten screws securely.

7.

Tighten set screw securely.

3. FAN WOBBLES

EXCESSIVELY

1.

Setscrew in downrod support is loose.

2.

Setscrew in downrod/hanger ball assembly is loose.

3.

Screws securing fan blade holders to flywheel are

loose.

4.

Blade holders not seated properly.

5.

Hanger bracket and/or ceiling outlet box is not

securely fastened.

6.

Fan blades out of balance.

1.

Tighten both setscrews securely in downrod support.

2.

Tighten the setscrew in the downrod/hanger ball

assembly.

3.

Check to be sure screws which attach the fan blade

holders to the flywheel are tight.

4.

Check to be sure the fan blade holders seat firmly

and uniformly to the surface of the motor housing. If

holders are seated incorrectly, loosen the screws and

retighten.

5.

Tighten the hanger bracket screws to the outlet box,

and secure outlet box.

6.

Interchanging position of fan blades can redistribute

the weight and result in a smoother operation. For

example, exchange blades in positions 1 and 3 or 1 and

4. If this does not improve wobble, exchange 2 and 4 or

2 and 5.

4. NOT ENOUGH AIR

MOVEMENT

1.

If possible, consider using a longer downrod. For

example, use a 12” downrod instead of the 6” downrod

that comes with your fan.

2.

Change your blade configuration from 5 blades to 4

blades. The flywheel will accomodate both a 5-blade

and 4-blade configuration.

3.

Consider using a narrow blade instead of the wide

oval. Narrow blades are available in the palm leaf and

woven bamboo series.

Summary of Contents for Louvre FP1320 Series

Page 15: ......