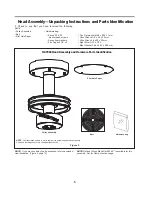

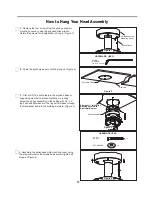

8. CAUTION: To reduce the risk of personal injury, mount the fan head assembly to a ceiling joist or structural member using

9. This fan is to be used in dry location only.

the hardware provided with your fan.

Important Safety Instructions

WARNING:

To avoid fire, shock and serious personal injury, follow these instructions.

1. Read your owner’s manual and safety information before installing your new fan. Review the accompanying assembly

diagrams.

2. Before servicing or cleaning unit, switch power off at service panel and lock service panel disconnecting means to prevent

power from being switched on accidentally. When the service disconnecting means cannot be locked, securely fasten a

warning device, such as a tag, to the service panel.

3. Be careful of the fan and blades when cleaning, painting, or working near the fan. Always turn off the power to the ceiling

fan before servicing.

4. Do not insert anything into the fan blades while the fan is operating.

Additional Safety Instructions

1. To avoid possible shock, be sure electricity is turned off at the fuse box before wiring, and do not operate fan without

blades.

2. All wiring and installation procedures must satisfy National Electrical Codes (ANSI/ NFPA 70-1999) and Local Codes. The

ceiling fan must be grounded as a precaution against possible electrical shock. Electrical installation should be made or

approved by a licensed electrician.

3. The complete fan must be securely mounted and capable of reliably supporting at least 50 lbs. (fan and accessories not to

exceed 50 lbs. or 22.70 kgs.). See page 6 of owner’s manual for support requirements. Consult a qualified electrician if in

doubt.

4. The fan must be mounted with the fan blades at least 7 feet from the floor to prevent accidental contact with the fan blades.

5. Follow the recommended instructions for the proper method of wiring your ceiling fan. If you do not have adequate

electrical knowledge or experience, have your fan installed by licensed electrician.

6. Suitable for use with solid-state speed controls.

TO REDUCE THE RISK OF ELECTRIC SHOCK, THIS FAN MUST BE INSTALLED WITH A GENERAL USE,

ISOLATING WALL CONTROL/SWITCH.

WARNING:

WARNING:

This product is designed to use only those parts supplied with this product and/or accessories designated

specifically for use with this product. Using parts and/or accessories not designated for use with this product could result in

personal injury or property damage.

WARNING:

To reduce the risk of personal injury, do not bend the blade bracket (flange or blade holder) when installing the

WARNING:

Motor assembly mount to an outlet box marked acceptable for fan support.

WARNING:

Do not operate this fan with a variable (Rheostat) wall controller or dimmer switch. Doing so could result in

damage to the ceiling fan's remote control unit.

WARNING:

To reduce the risk of fire, electric shock, and injury to persons, ceiling-suspended fan, model FP7966 series must

be installed with fan head assembly that are marked on their cartons to indicate the suitability with this model. Other fan head

assembly cannot be substituted.

brackets, balancing the blades, or cleaning the fan. Do not insert foreign objects in between rotating fan blades.

LIMITED LIFETIME WARRANTY

Extends to the original purchaser of a Fanimation Fan

1. LIMITED LIFETIME MOTOR WARRANTY - If any part of your fan motor fails, due to a defect in materials or workmanship

during the lifetime of the original purchaser, Fanimation will provide the replacement part free of charge, when the defective

fan is returned to our national service center. Proof of purchase is required. Customer shall be responsible for all costs

incurred in the removal or reinstallation and shipping of the product for repairs or replacement.

2. ONE YEAR MOTOR LABOR WARRANTY - If your fan motor fails at any time within one year from the original purchase, due

to defects in materials or workmanship, labor to repair the motor will be provided free of charge at our national service

center. Purchaser will be responsible for labor charges after this one-year period. Customer shall be responsible for all

costs incurred in the removal or reinstallation and shipping of the product for repairs or replacement.

3. If any other part of your fan fails at any time within one year after original purchase, due to a defect in materials or

workmanship, we will repair, or replace, at our option, the defective part free of charge for parts and labor performed at our

national service center.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation. If the intentional radiator can be classified as a Class B digital device or a PC

peripheral, then shall include the following or equivalent:

Note:

This equipment has been tested and found to comply with the limits for Class B digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and the receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

Note:

For a Class A digital device, statements of 15. 105(a) must be included when appropriate for the device in question.

6. The appliance is not intended for use by young children or infirm persons without supervision. Young children should be

supervised to ensure that they do not play with the appliance.

7. For supply connections, if the conductor of a fan is identified as a grounded conductor, then it should be connected to a

grounded conductor power supply. If the conductor of a fan is identified as an ungrounded conductor, then it should be

connected to an ungrounded conductor power supply. If the conductor of a fan is identified for equipment grounding, then it

should be connected to an equipment-grounding conductor.

5. Do not operate reversing switch until fan blades have come to a complete stop.