7

SECTION 3

SPRING CALIBRATION PROCEDURE

MODEL 280 RHEOMETER

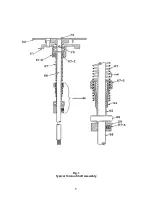

This procedure requires the removal of the Torsion Shaft Assembly, shown in Fig.1, from the

Rheometer, and mounting it in the Calibration Fixture.

A.

Torsion Shaft Assembly Removal

1.

Unscrew and remove the Sleeve, Bob, and Dust Shield from the Rheometer.

2.

Place Rheometer speed shift lever in 300 RPM speed setting.

3.

Remove flat head screw from center of Gel Knob.

4.

Holding Gel Knob loosen hex set screw 1/4 turn using a hex key wrench and, then

unscrew and remove Gel Knob.

5.

Move Speed shift lever to the STIR position and pull shift arm, cam, and bearing

off shift rod.

6.

While holding rotor from turning, turn crank backward thereby unscrewing and

removing it.

7.

Remove four 6-32 x 1/4 long screws holding cover to frame, then pull cover up and

off Rheometer.

8.

Remove flat head screw [79] from top center of dial, then carefully lift dial straight

up and remove.

9.

Loosen two Zeroing screws that act as set screws against the flat on the Torsion

Body, sufficiently to clear and allow removal of the torsion body.

10.

Remove the large retainer ring on top of the Torsion Body.

11.

Lift the torsion shaft assembly up and out of the Rheometer frame.

12.

Re-assemble the Dial [60] onto the top of the Bob Shaft and secure it with screw

[79].

B.

Preliminary Spring Setting

A preliminary setting of the torsion spring should be made prior to mounting it in the fixture.

Make this setting as follows:

1.

Set the torsion spring assembly for approximately 9-1/4 to 9-1/2 pair turns by

rotating the outer collet [67-3]. (Refer to Fig. 1) on spring [67] to the proper point.

2.

Grasp the flats on lock collet [64] with needle nose pliers between lower spring

coils. Holding the dial [60] turn it, torsion shaft, and collet [65] clockwise to loosen

the thin notched portion of lock collet [64] from the spring [67]. and collet 67-3].

3.

Slide the spring, with the outer collet [67-3] on it, over lock collet [64] until top of

collet [67-3] is approximately even with top of lock bushing [65].

Summary of Contents for 280

Page 5: ...2 ...

Page 8: ...5 Fig 1 Typical Torsion Shaft Assembly ...

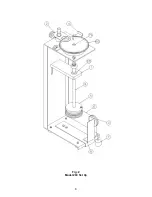

Page 9: ...6 Fig 2 Model 280 Set Up ...

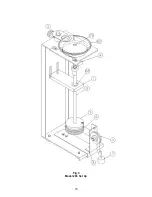

Page 13: ...10 Fig 3 Model 286 Set Up ...