14

Make sure all holes in the circuit board are in line and nothing is binding the

circuit board as it is assembled into place.

Make sure the two top mounting holes are in line and the holes for the

power transistor and voltage regulator are in line.

7.

Mount the circuit board by installing the following screws:

Two screws from the top of the PC board into the frame

One screw holding the power transistor to the frame

One screw holding the voltage regulator to the frame

8.

Assemble the dial [60] and secure with screw [79].

9.

Temporally place the cover, with the hairline jewel in it, in place and observe the

position of the hairline with relation to the "0" on the dial.

Remove the cover and adjust the two zeroing screws on the right side of the frame

and against the flat on the Torsion Body. Loosen one and tighten the other to

slightly rotate the torsion body as needed to align the "0" with the hairline.

Recheck using the cover and repeat if necessary. Both zero adjust screws should

be tight against the torsion body when adjustment is complete.

10.

Install Cover be installing the following fasteners:

Two 6-32 x 1/4 long cover to frame screws

Two 6-32 x 1/4 long cover to power supply bracket screws.

Nut cover to speed selector switch

Nut cover to variable speed potentiometer. (Use socket wrenches or nut

drivers).

11.

Install switches. Use hex key wrenches to tighten their set screws. Make sure

these set screws are seated on the flats on the switch shafts.

Power ON/OFF switch

Speed selector switch knob

Variable speed control

12.

Assemble the Dust Shield and the Bob onto the Bob Shaft, then screw the Sleeve

onto the Rotor.

13.

Connect the Model 286 Rheometer to the power source and test its performance.

NOTE: This spring calibration should be verified after assembly of

Rheometer by the silicone oil calibration method. Refer to

Model 286 Instructions.

Summary of Contents for 280

Page 5: ...2 ...

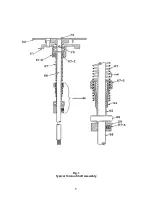

Page 8: ...5 Fig 1 Typical Torsion Shaft Assembly ...

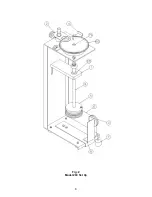

Page 9: ...6 Fig 2 Model 280 Set Up ...

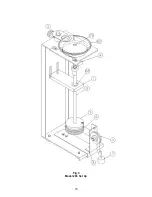

Page 13: ...10 Fig 3 Model 286 Set Up ...