17

fantech

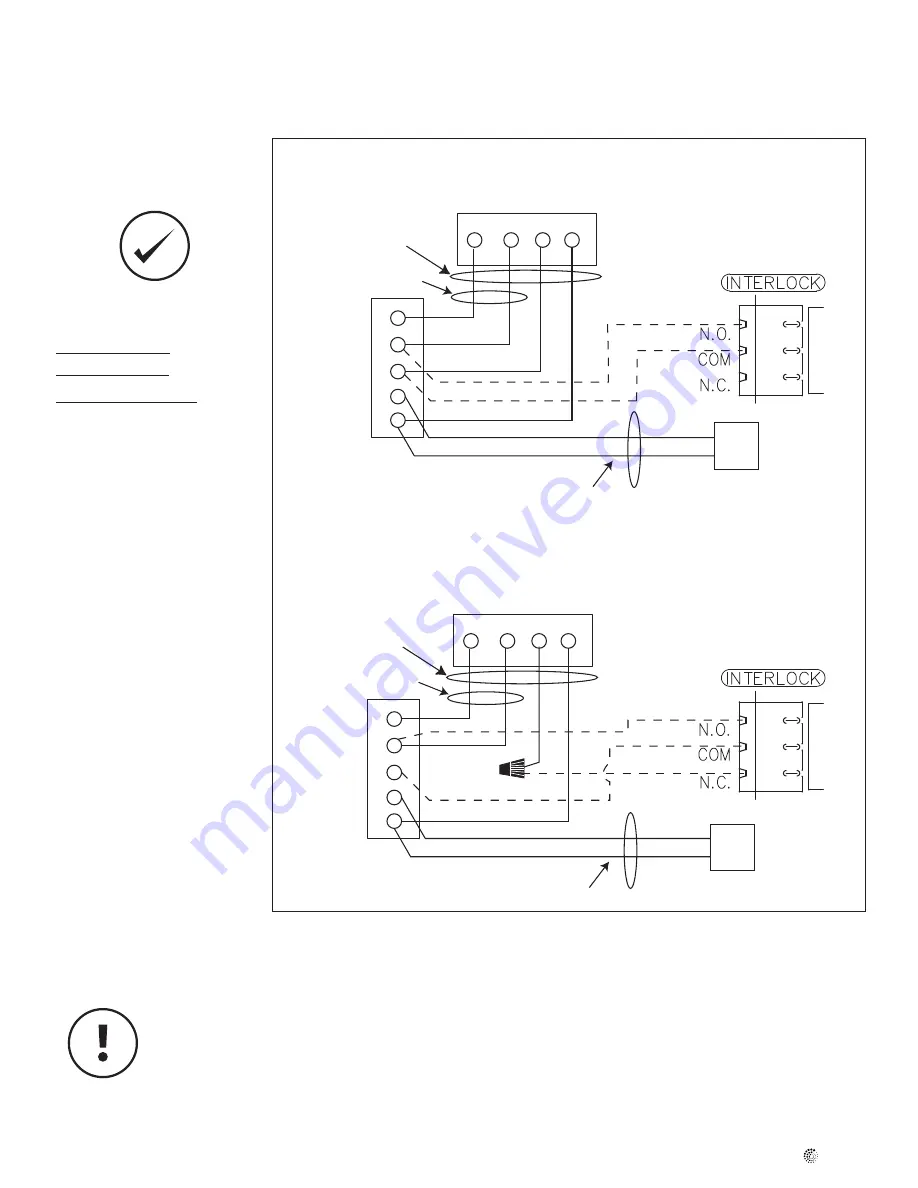

W

R

G

C

Y

W

R

G

Y

Standard Furnace Interlock Wiring

THERMOSTAT

TERMINALS

FURNACE

24-VOLT

TERMINAL BLOCK

FOUR

WIRE

TWO WIRE

heating only

TWO

WIRE

COOLING SYSTEM

W

R

G

C

Y

W

R

G

Y

Alternate Furnace Interlock Wiring

THERMOSTAT

TERMINALS

FURNACE

24-VOLT

TERMINAL BLOCK

FOUR

WIRE

TWO WIRE

heating only

TWO

WIRE

COOLING SYSTEM

WIRE JOINT

WIRING DIAGRAM

(CONT'D)

WIRING DIAGRAM TO

FURNACE

FOR A FURNACE

CONNECTION TO

A COOLING SYSTEM:

On some newer furnaces and older

thermostats, energizing the R and

G terminal at the furnace has the

effect of energizing the Y at the

thermostat and thereby turning on

the cooling system. If you identify this

type of thermostat, you must use the

“Alternate Furnace Interlock Wiring”

Standard Accessory Control Contact

Alternative Accessory Control Contact

As per building codes and installation requirements for combustion appliances:

Air return ducts, or openings for air return, should not be placed in enclosed spaces containing combustion

appliances that are subject to spillage.

Summary of Contents for 99286

Page 22: ...22 fantech Notes ...

Page 23: ...23 fantech Notes ...