6

fantech

Wiring Procedure

Step 1.

Remove the screws securing the terminal box cover plate located on the

side of the fan. All fan motor connections are prewired to an electrical

terminal strip. A 3/8" romex type cable restraint connector will be

needed to secure the wiring through the knockout provided on the side of

the terminal box.

Step 2.

Bring incoming electrical service through the romex connector and the

fan knockout. Be sure to place the connector nut over the wiring coming

into the terminal box. There are three open ports on the terminal strip.

Using a small regular screwdriver, tighten the Neutral (White) wire of the

incoming supply under the open terminal labeled "N". Tighten the Line

(Black) wire of the incoming supply under the open terminal labeled "L".

Tighten the Ground (Green) wire of the incoming supply under the open

terminal marked " ". For reference, a wiring diagram is included on

the inside of the terminal box lid.

Step 3.

Secure the romex connector. Secure the incoming supply with the romex

connector. Replace the fan terminal box cover.

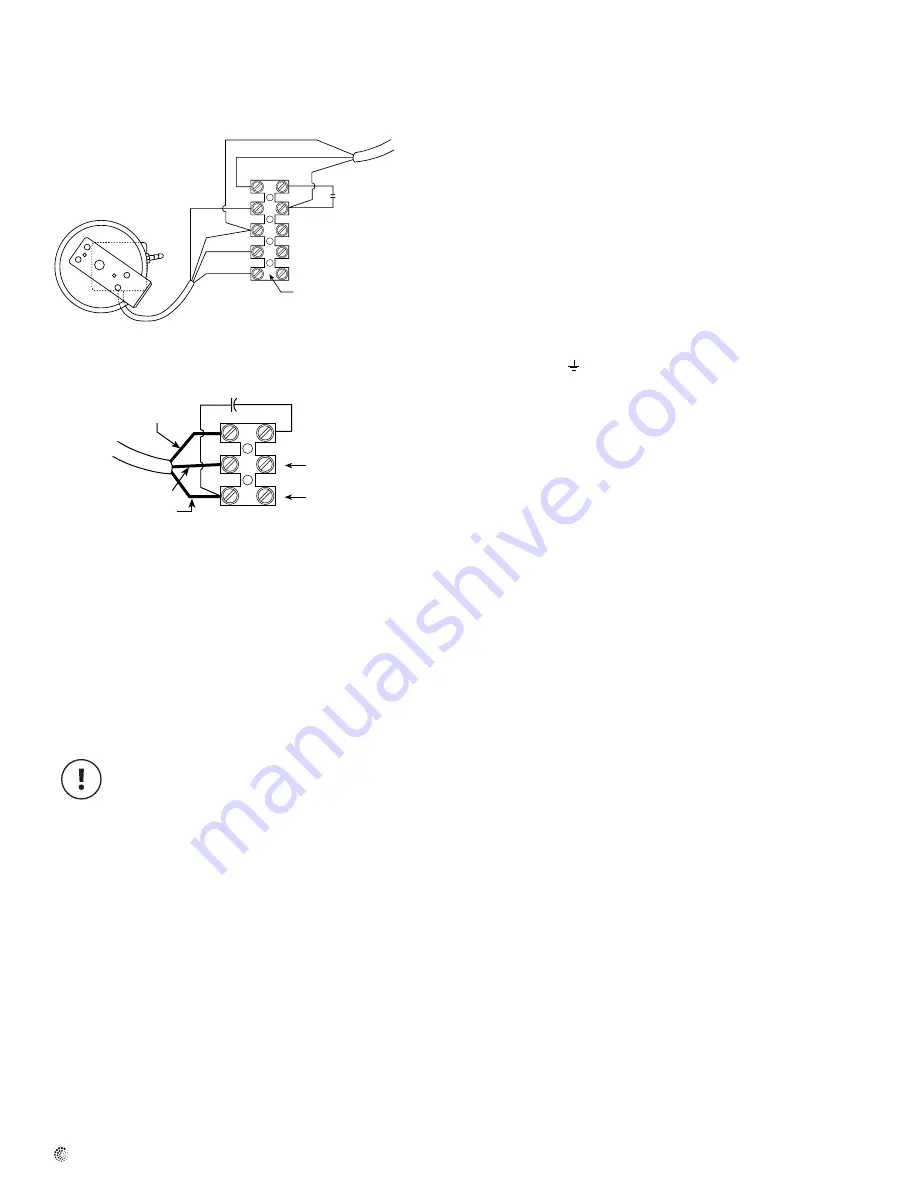

Illustration 5

DBF110 Wiring – Fan and Pressure Switch

Blue

Brown

Power

to Fan

Red

White

Black

Green

Terminal block in

fan wiring box

Neutral

115V Line (Supply) Electrical supply, 115V

Ground

Capacitor

Motor

Leads

Brown (Z2)

Blue (U2)

Black (TK)

Capacitor

Neutral side of

115V supply

Line side of

115V supply

Fan Only Wiring (Reference for Troubleshooting Step 8c)

Black

N

L

Maintenance

Prior to performing Steps 1 - 4, be certain that the electrical

supply to the fan/switch is turned off.

If fan fails to start when the dryer cycle begins, please follow the

procedure listed below:

1. Check the incoming supply for proper voltage.

2. Consult schematic shown above (also included on inside of fan wiring

terminal lid) to ensure proper connection.

3. If possible, use a meter to test for continuity across the fan motor

leads. In order to do this, the capacitor and pressure switch must be

disconnected (do not test the capacitor - it will not meter continuity).

If motor leads show continuity, rewire the fan, capacitor and

pressure switch.

4. Turn on the electrical supply and restart the dryer cycle. Check to be

certain that fan starts.

If fan still fails to start after performing Steps 1 – 4, continue following

the procedure as listed below:

5. Verify that the pressure switch diaphragm is vertical as shown in

Illustration 2 of these instructions. If the diaphragm is not vertical,

reposition the pressure switch and check for fan operation against

another dryer cycle.

6. Verify that the tubing is not crimped and that the tubing connector

nipples are not obstructed.

7. If switch diaphragm is vertical and fan still fails to start, with the

electrical supply on:

a. Remove the tubing from the nipple on the fan and blow gently

into the tubing;

b. If fan starts, consult Fantech for additional technical support.

8. If fan fails to start after blowing into the tubing:

a. Disconnect incoming power supply at the source.

b. Remove the pressure switch leads from the wiring terminal

block

c. Connect the incoming power supply directly to the fan motor

as shown in "FR110 Wiring" diagram below.

d. Turn on power to fan.

9. If fan fails to start, please consult Fantech for additional technical

support.

Recommended Maintenance

1. Since fan bearings are sealed and provided with an internal lubricating

material, no additional lubrication is necessary.

2. Fan impeller may accumulate lint. Periodic inspection, based upon

dryer usage, should be performed to ensure that the fan impeller is

not obstructed or loaded with lint. Under normal conditions, fan should

be inspected a minimum of every Six (6) Months. Note: Excessive

booster fan noise or vibration may be an indication of lint buildup on the

impeller. To inspect and clean the impeller:

a. Disconnect the incoming power supply at the source.

b. Remove the duct from the fan inlet and remove any lint buildup on the

impeller.

c. Reconnect the duct to the fan. Turn power supply on.

Troubleshooting