DBF110 DRYER EXHAUST BOOSTER SYSTEM INSTALLATION INSTRUCTIONS

DBF110 Includes:

1 DBF 110 Dryer Booster Fan

1 Fan Mounting Bracket and Hardware

1 Small Wall Sign Indicating Proper Operating Procedure

Important Notice

Read and Save these instructions for future reference.

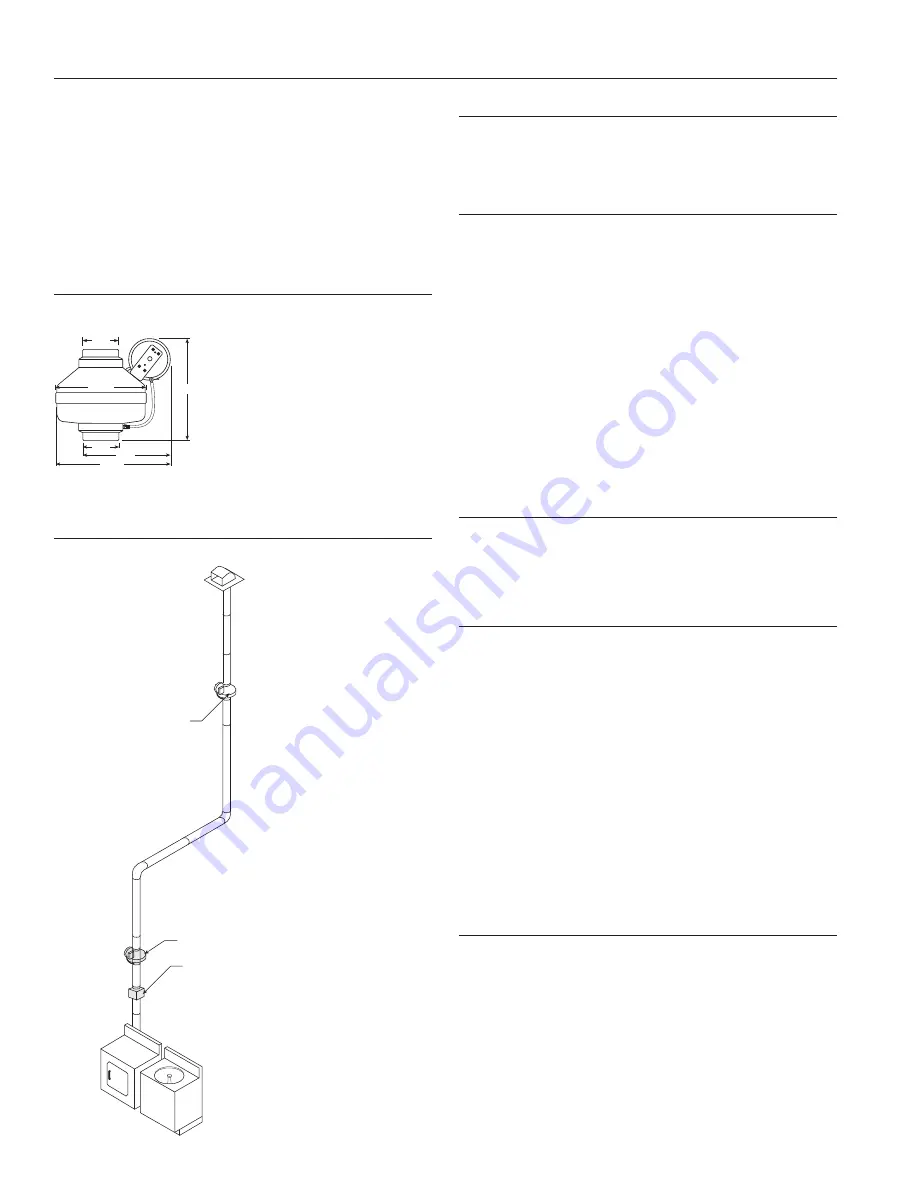

Dimensional Data

3

″

1

″

³|₄

″

4

″

12¹|₂

″

9¹|₂

″

4

″

9¹|₂

″

11¹|₄

″

4¹|₂

″

Illustration 1

(DBF110)

DBF110

Alternative Location

Secondary Lint Trap

Installation Guidelines

Please note: DBF 110 fans are not explosion proof. Do not use the fans if

a potentially explosive situation may exist.

DO NOT USE with heated air in excess 140˚F (60˚C).

Fan and Switch Mounting

The recommended location of the booster fan is a minimum of 15 linear (not

equivalent) feet of duct from the dryer outlet. If the fan is mounted closer

than the recommended 15 feet, it may develop enough pressure to lift wet

lint into the fan impeller resulting in excessive lint loading in the fan. The best

location for the fan to be mounted is as close as possible to the termination

of the duct work.

(Exception: If a secondary lint filter is installed between the

dryer and the booster fan, the booster fan may be mounted within the min-

imum distance otherwise recommended (See illustration to left). An NB

mounting bracket attached to a rafter or joist should be used to stabilize the

fan. Although not recommended, a vertical rigid duct may support the fan if

the duct is securely stabilized. (Consult local codes prior to supporting the

fan in the duct alone.) Duct work should be attached to the inlet and outlet

of the fan by means of FC vibration isolation clamps

(not included) or duct

tape. The duct connection should be properly sealed to prevent leakage and

loss of fan performance. Flex duct connections between the dryer duct con-

nection and exhaust duct should be stretched as smooth as possible.

Calculating Duct Run

To calculate the length of your planned duct run, measure from the dryer

to external venting point in roof or wall. For each bend or elbow add 5-7

feet to your total duct run calculations. The DBF4XL can be used on runs

up to 108 feet.

Pressure Sensor Switch Operation

Fantech’s DBF110 is equipped with Fantech's Patented DB10 pressure

switch. The DB10 is a positive pressure sensing switch which

recognizes dryer operation and activates the booster fan from an

independent electrical circuit. This eliminates connections through the

dryer circuit which may void the manufacturers’ warranty as well as man-

ual systems which require the attention of the operator or costly cur-

rent/temperature sensing systems.

The electricity to the booster fan is connected in series through a

normally open terminal on the switch. A pressure tap is connected to a

fitting on the side of the switch. When the dryer begins operation, posi-

tive pressure in the duct causes the switch diaphragm to expand, closing

the circuit to the booster fan. An integral delay-on-break timer in the

switch will cycle the fan on for intervals of 10 minutes. This will continue

until the dryer has stopped and the timer delay period has lapsed. Drying

cycles, the booster fan, the delay timer and the pressure switch are not

adversely affected by the starting/stopping intervals.

Fan Installation

Step 1. Selecting Fan Location

Fan

must

be mounted a minimum of 15 feet from the dryer outlet.

If the fan is mounted closer than the recommended 15 feet, it may devel-

op enough pressure to lift wet lint into the fan impeller resulting in exces-

sive lint loading in the fan.

(Exception: If a secondary lint filter is installed

between the dryer and the booster fan, the booster fan may be mounted

within the minimum distance otherwise recommended (See illustration to

left). The best location for the fan to be mounted, in any application, is as

close as possible to the termination of the duct work. In order to perform

recommended maintenance, fan location should allow sufficient access

for service. Refer to dimensional drawings shown above.