15

Airflow balancing

(Cont'd)

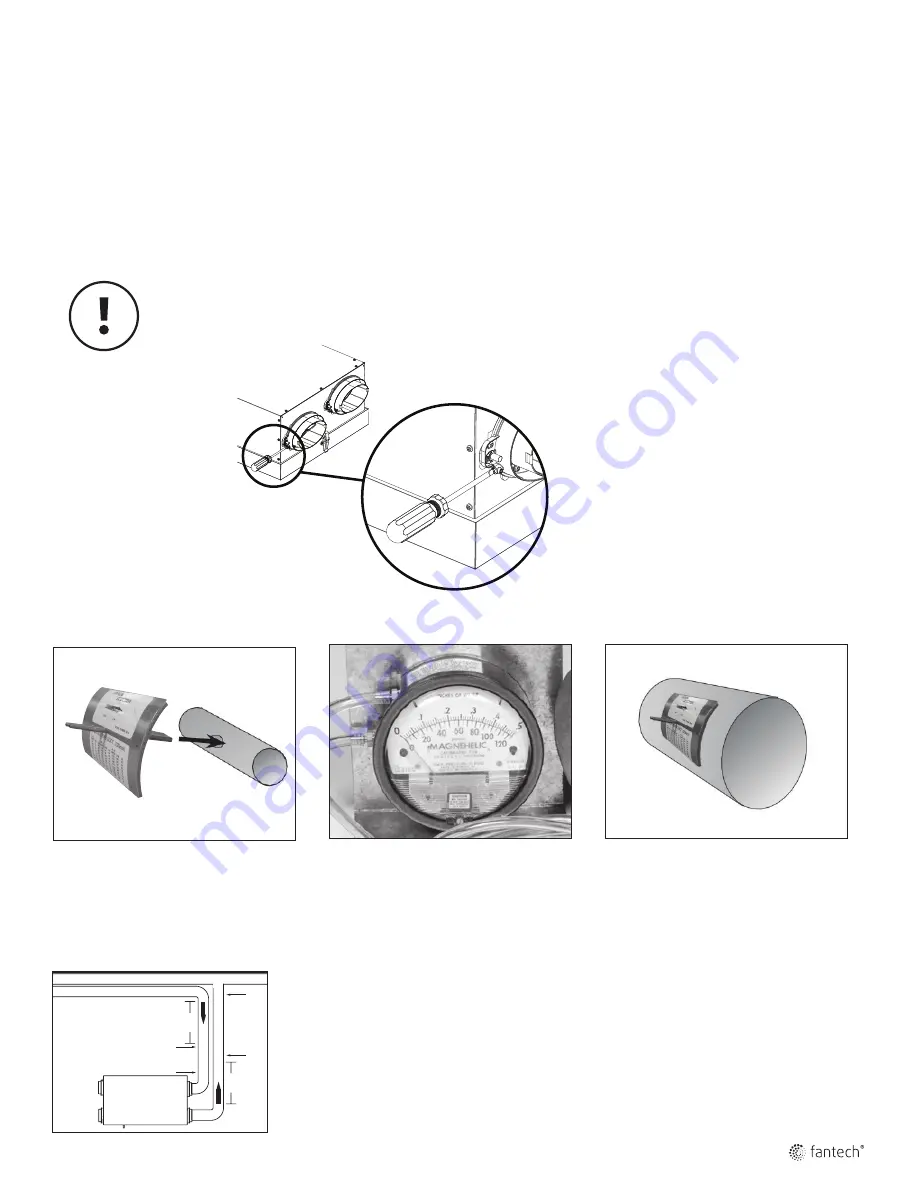

1

Cut hole in duct and insert flow measuring

station. Make sure that the flow measuring

station’s air direction arrow points in the

direction of the airflow. Secure the flow

measuring station with aluminum foil tape.

2

Before taking the reading, make sure that

the magnehelic gauge is level and at 0.

Refer to the flow measuring station’s

chart to determine your unit’s airflow

velocity.

3

Adjust the “Supply Air Out” damper until

you reach the desired velocity. Follow

steps 1-3 to adjust the “Exhaust Air Out”

damper, if needed.

Measure

here

Minimum

457mm

(18")

Measure

here

Minimum

457mm (18")

• To avoid airflow turbulence and incorrect

readings, the airflow velocity should be

measured on a section of steel ducting.

Reading should also be taken at a minimum

distance of 457 mm (18") from the unit or

elbow. Measurement should also be made

prior to any transition in the duct work so

entire airflow is measured.

Measuring the airflow using station (grid) method

Adjusting airflows

A damper is integrated into the Fresh Air to Building collar. This damper replaces the installation of a separate damper into the Fresh

Air to Building ducting line.

The damper-collar is pre-set in the fully opened position. If the procedure requires a reduction in airflow to the fresh air duct, simply

turn the adjustable arm located on the side of the collar counter clockwise until desired airflow is obtained.

WARNING! DO NOT TURN ADJUSTABLE ARM CLOCKWISE WHEN DAMPERS ARE FULLY OPENED AS DAMAGE MAY OCCUR TO THE

MECHANISM

Illustration #1

Summary of Contents for FIT 120E

Page 18: ...18 Wiring diagram Observe polarity on all accessory controls where applicable ...

Page 46: ...46 Note ...

Page 47: ...47 Note ...