7

Maintenance

MAKE SURE UNIT IS UNPLUGGED BEFORE ATTEMPTING ANY MAINTENANCE WORK

The following components should also be inspected regularly and well maintained.

Filters

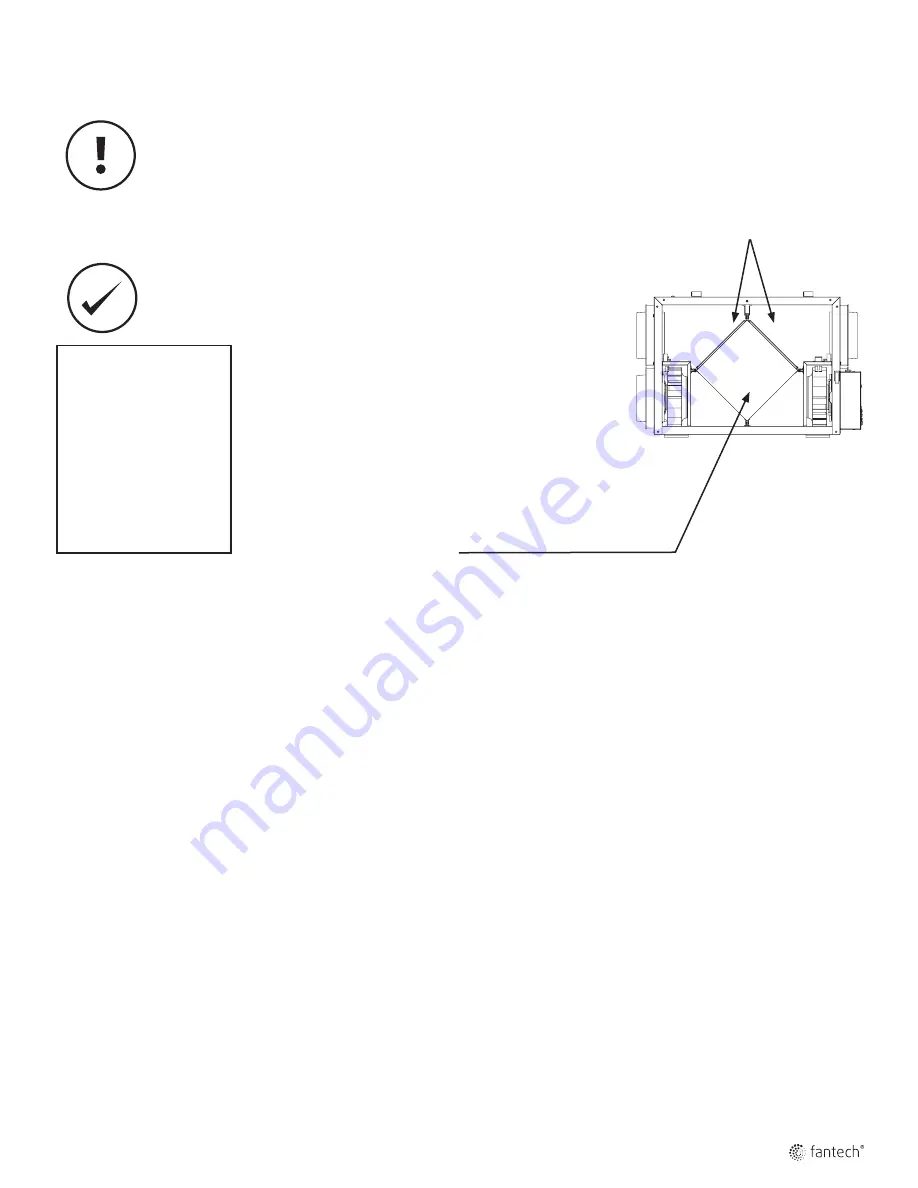

The filters (2) need to be checked and cleaned every

three months or when they appear dirty. Wash in

warm sudsy water (mild detergent) or use a soft

brush vacuum. The filters should be replaced when

they can no longer be cleaned properly.

Heat recovery core

The heat recovery core needs to be checked and cleaned every six months. The core can be cleaned

using a mild soap and water. Rinse thoroughly. Handle with care. Hot water and a strong detergent

will damage the heat recovery core. It is recommended to clean the core in the summer or when the

temperature is mild. Never clean in the heat recovery core in the winter.

Clean Core and Filters Every 3-6 Months.

Unplug unit before doing any repairs or maintenance

a) Open access door.

b) Carefully grip handle of core and pull out. Core will slide out of the channel.

c) Once removed from the cabinet remove filters.

d) Wash core in warm soapy water (do not use dishwasher).

e) Install clean core by:

a) First mounting the bottom flange of the core guide into the bottom channel approximately

1/4” (6mm).

b) Mount the left or right side flange of the core guide approximately 1/4 “ (6mm) followed

by the other side.

c) Mount the top flange of the core guide into the top channel approximately 1/4” (6mm).

d) With all four corners in place and the core straight and even, push hard in the centre of

the core until the core stops on the back of the cabinet.

f) Install the clean filters.

• To prevent electrical shock,

check that the unit is

unplugged before doing any

repairs or maintenance.

• A yearly inspection is

recommended to ensure the

efficiency and trouble-free

use of your system. Run

through the system and

verify the different operating

modes.

The motor

– The motors are factory

balanced and lubricated for life.

They require no maintenance.

The unit

– The inside of the unit

should be vacuumed yearly. Be

careful not to damage any of

the mechanical components and

electrical connections.

The drain pan and drain line

– Units

with drain line should have their line

and connection checked regularly.

Outside hood

– The outside hoods

need to be checked every season

to make sure there no leaves

or insects blocking the airflow.

Check regularly that they're are no

pollutants near the intake hood.

Make sure they are clear of any

snow accumulation during the

winter months.

Filters need to be checked regularly

Summary of Contents for VHR Series

Page 10: ...10 Notes...