13

WORKSHOP MANUAL

TL 250

CHAPTER 2

MAINTENANCE RULES

Part

Screw

Torque setting Nm

Triple clamp screw

M8 (08.8)

18

M8 (10.9)

25 +

243

Wheel axle

M14

50

Rear wheel axle nut

M17

80

M8 (08.8)

25

M8 (08.8)

25

M10 (08.8)

45

Clutch/Brake pump collars

Engine mounting screws diameter 10

Engine mounting screws diameter 8

M6 (10.9)

10

M10

45

M8

25

Swingarm pivot bolt

M14

60

Linkage

M

12

50

Rear shock

Sprocket screws

M10 upper

40

M

10 lower

40 +

243

M8 (10,9)

25

Front brake disc screws

M8

25 +

243

Rear brake disc screws

M6

10 +

243

Kickstand screw

M8 (10.9)

25

Rear brake lever screw

M10 (8.8)

40

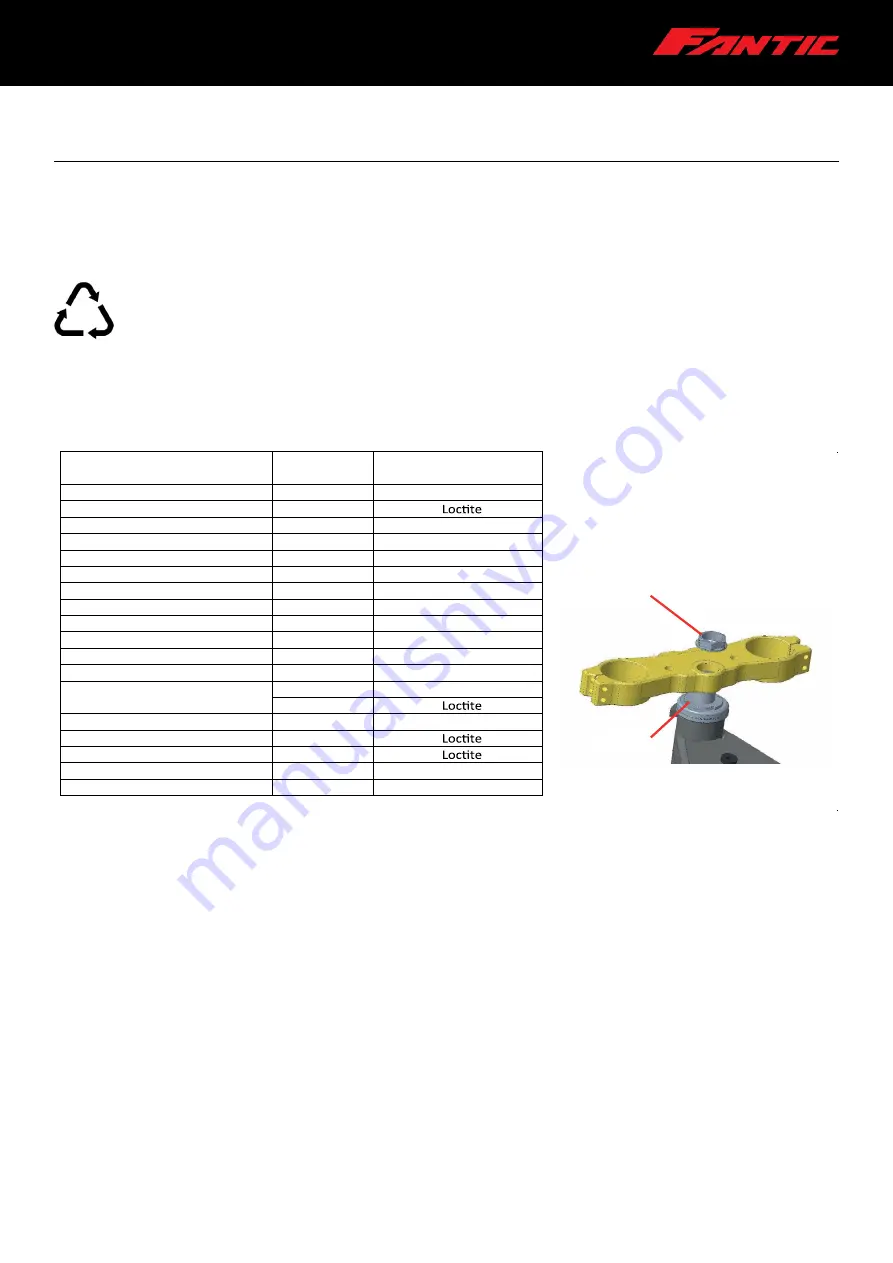

STEERING STEM FASTENING SEQUENCE:

1. Tighten the ring nut to 25Nm;

2. Loosen the ring nut ½ a turn;

3. Retighten the ring nut to 8 Nm;

4. Fit the upper triple clamp;

5.

Tighten the top nut to 80 Nm.

NUT

RING NUT

Front brake caliper screws

Fork axle clamp screws

Handlebar bolts

Handlebar bolts

!

Keep all parts away from sources of heat.

Do not lift the vehicle by its licence plate bracket, to avoid damage.

Use suitable tools and cleaning products.

2.3 TORQUE SETTINGS

Summary of Contents for TL 250

Page 1: ...1 WORKSHOP MANUAL E N...

Page 3: ...WORKSHOP MANUAL TL 250...

Page 11: ...11 WORKSHOP MANUAL TL 250...

Page 30: ...30 WORKSHOP MANUAL TL 250 CHAPTER 6 DASHBOARD 39 GENERAL CONTENT AND CONSULTATION ENGLISH...

Page 49: ...49 49 WORKSHOP MANUAL TL 250...

Page 51: ...51 CHAPTER 15 ELECTRICAL DEVICES 51 WORKSHOP MANUAL TL 250...

Page 136: ...136 136 WORKSHOP MANUAL TL 250...