01

Safety switch

02

Table

03

Vice

04

Table adjustment

05

Table inclination

06

Capstan

07

Belt tension

08

-

09

Chuck guard

10

Pulley hood

11

Depth-stop

12

-

13

-

14

-

15

-

16

-

01

Column assembly

02

-

03

Head assembly

04

-

05

Securing the machine

01

Belt tension

02

-

03

Setting the drawback spring

04

-

01

Starting and stop

02

-

03

Table orientation

04

Use of butted of depth

05

How to change speed

06

-

07

-

08

-

09

-

10

Drilling a hole

EN

EN

Description and location of machine parts

Maintenance, recommendations and advice

Contents of box

Assembling the machine

Functions of the machine

Settings of the machine

FIG. A

FIG. B

FIG. C

FIG. D

FIG. E

01

-

02

-

01

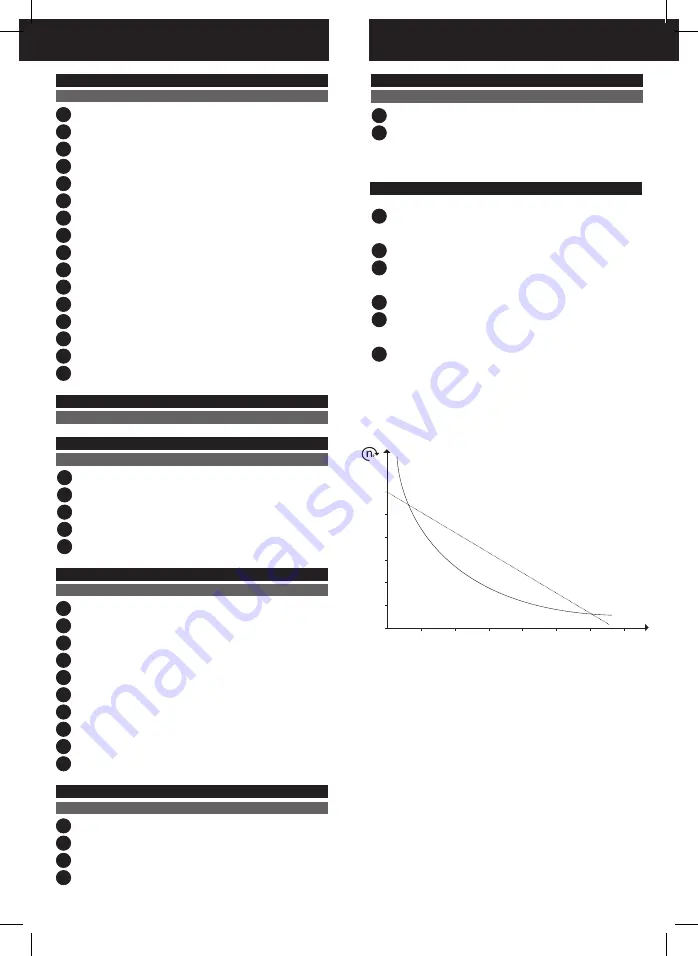

The use of suitable accessories in good condi-

tion will ensure the machine operates optimally

02

Spindle lubrication

03

To avoid rust, grease machined metal parts

( table, column, etc.)

04

Check the condition of the belts regularly

05

Lubricate the bit when drilling with a mixture of

soluble oil and water

06

Adapt the rotation speed of the chuck to the

diameter of the drill:

- Small diameter = high speed

- Large diameter = low speed

Replacing consumables

FIG. F

3000

2500

2000

1500

1000

500

0

5

10

15

20

25

30

2800 min

-1

= 3 mm

300 min

-1

= 30 mm

ø (mm)

Summary of Contents for P 13F

Page 8: ...01 11 10 09 02 05 03 04 06 07 FIG A...

Page 9: ...x 3 FIG B x 1 1 5 13 mm...

Page 10: ...01 03 FIG C...

Page 11: ...05...

Page 12: ...01 03 FIG D...

Page 13: ...50 mm 50 mm 04...

Page 14: ...05 2620 1880 1370 900 520 1 2650 2 1650 3 1220 4 850 5 580 2620 1880 1370 900 520...

Page 15: ...10 10mm 01 FIG E...

Page 16: ...03 1 2 1 2 1 2 1 2...

Page 48: ...P 13F...