©

FAR GROUP EUROPE

WARNING: Never release lever 2 until the thread cutting is finished

To reset the tool in the start position, reverse the chuck direction and repeat a number of

0.25 mm passes to achieve the final 1.3925 mm dimension, Try the M 20 x 2.5 bolt before

disengaging the centre gage lever 2

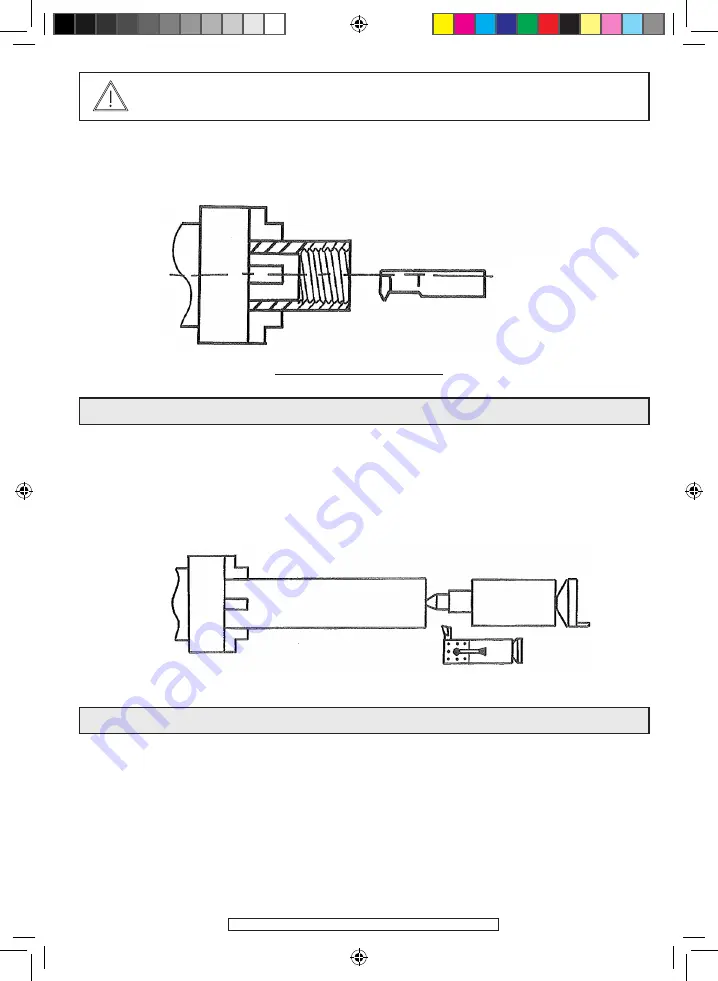

The mixed fitting mode is used when the part, once clamped in the chuck, protrudes

from it by more than twice its diameter.

Tighten the part in the chuck, Drill a centre hole using a centring bit, Then bring up

the tailstock centre (114317), the mounting is a rigid one and it is possible to safely ma-

chine.

The fitting between tailstocks mode is used to produce axes that require perfect concen-

tricity between all diameters. To do this, it is necessary to drill a centre hole through both

ends of the axis to be machined. Then take the chuck apart and fit the dry tailstock and

place the part to be milled between the dry tailstock and the spinning one (114317).

Drive is achieved with a toc

MIXED FITTING

FITTING BETWEEN TAILSTOCKS

OTHER MILLING MODES

Metric

threading

114135-Manual-D-EN.indd 22

21/03/12 10:45:00

Summary of Contents for TDM 400B

Page 5: ...FAR GROUP EUROPE SLAVED SAFETY CASING 114135 Manual D EN indd 5 21 03 12 10 44 23...

Page 13: ...FAR GROUP EUROPE 114135 Manual D EN indd 13 21 03 12 10 44 55...

Page 29: ...FAR GROUP EUROPE FAR GROUP EUROPE TDM 400B 114135 Manual D EN indd 29 21 03 12 10 45 06...

Page 30: ...FAR GROUP EUROPE TDM 400B 114135 Manual D EN indd 30 21 03 12 10 45 06...

Page 31: ...FAR GROUP EUROPE TDM 400B 114135 Manual D EN indd 31 21 03 12 10 45 06...

Page 32: ...FAR GROUP EUROPE TDM 400B 114135 Manual D EN indd 32 21 03 12 10 45 07...

Page 33: ...FAR GROUP EUROPE TDM 400B 114135 Manual D EN indd 33 21 03 12 10 45 07...

Page 34: ...FAR GROUP EUROPE TDM 400B 114135 Manual D EN indd 34 21 03 12 10 45 07...

Page 35: ...FAR GROUP EUROPE TDM 400B 114135 Manual D EN indd 35 21 03 12 10 45 08...

Page 36: ...FAR GROUP EUROPE TDM 400B 114135 Manual D EN indd 36 21 03 12 10 45 08...