©

FAR GROUP EUROPE

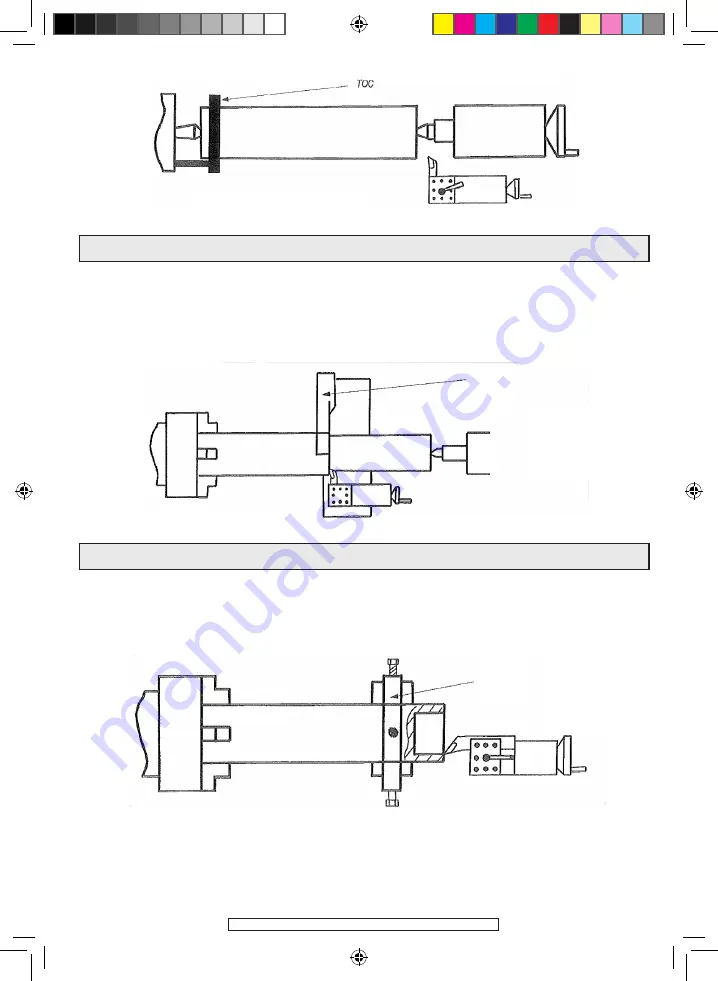

A steady is used when machining very long axes and when the tailstock centre can be

used. The steady is mounted on the longitudinal carriage and the brass pads or ball

bearings are positioned on the opposite side to the tool. This avoids vibration (therefore

ensuring good quality machining).

A fixed steady is used when machining very only axes when the tailstock centre cannot

be used (boring, thread cutting). The fixed steady is mounted on the bench between the

chuck and the tool carrier carriage

FITTING WITH A STEADY (OPTION 114300)

MOUNTING WITH A FIXED STEADY (OPTION 114320

fitting between tailstocks

fitting with a

steady

steady

fixed

steady

fitting with a

fixed steady

114135-Manual-D-EN.indd 23

21/03/12 10:45:01

Summary of Contents for TDM 400B

Page 5: ...FAR GROUP EUROPE SLAVED SAFETY CASING 114135 Manual D EN indd 5 21 03 12 10 44 23...

Page 13: ...FAR GROUP EUROPE 114135 Manual D EN indd 13 21 03 12 10 44 55...

Page 29: ...FAR GROUP EUROPE FAR GROUP EUROPE TDM 400B 114135 Manual D EN indd 29 21 03 12 10 45 06...

Page 30: ...FAR GROUP EUROPE TDM 400B 114135 Manual D EN indd 30 21 03 12 10 45 06...

Page 31: ...FAR GROUP EUROPE TDM 400B 114135 Manual D EN indd 31 21 03 12 10 45 06...

Page 32: ...FAR GROUP EUROPE TDM 400B 114135 Manual D EN indd 32 21 03 12 10 45 07...

Page 33: ...FAR GROUP EUROPE TDM 400B 114135 Manual D EN indd 33 21 03 12 10 45 07...

Page 34: ...FAR GROUP EUROPE TDM 400B 114135 Manual D EN indd 34 21 03 12 10 45 07...

Page 35: ...FAR GROUP EUROPE TDM 400B 114135 Manual D EN indd 35 21 03 12 10 45 08...

Page 36: ...FAR GROUP EUROPE TDM 400B 114135 Manual D EN indd 36 21 03 12 10 45 08...