Revisione - 03

Date 01-2011

15

GB

KJ 45/S

KJ 45/S

f3

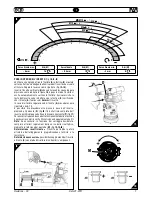

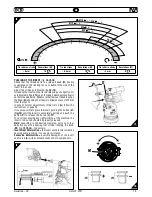

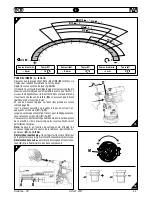

Tie rod min. stroke

Revolutions (M)

~ 2 mm

0

Tie rod stroke

Revolutions (M)

~ 0.4 mm

1

Tie rod max. stroke

Revolutions (M)

~ 8 mm

15

0

1

2

3

4

5

6

7

9

8

10

11

12

13

14

15

M12

1 ÷ 4

M4

0.3 ÷

4

M5

0.5 ÷ 5

M8

0.8 ÷ 6

M10

1 ÷ 6

M12

1 ÷ 7

/

M6

0.5 ÷ 6

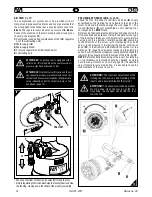

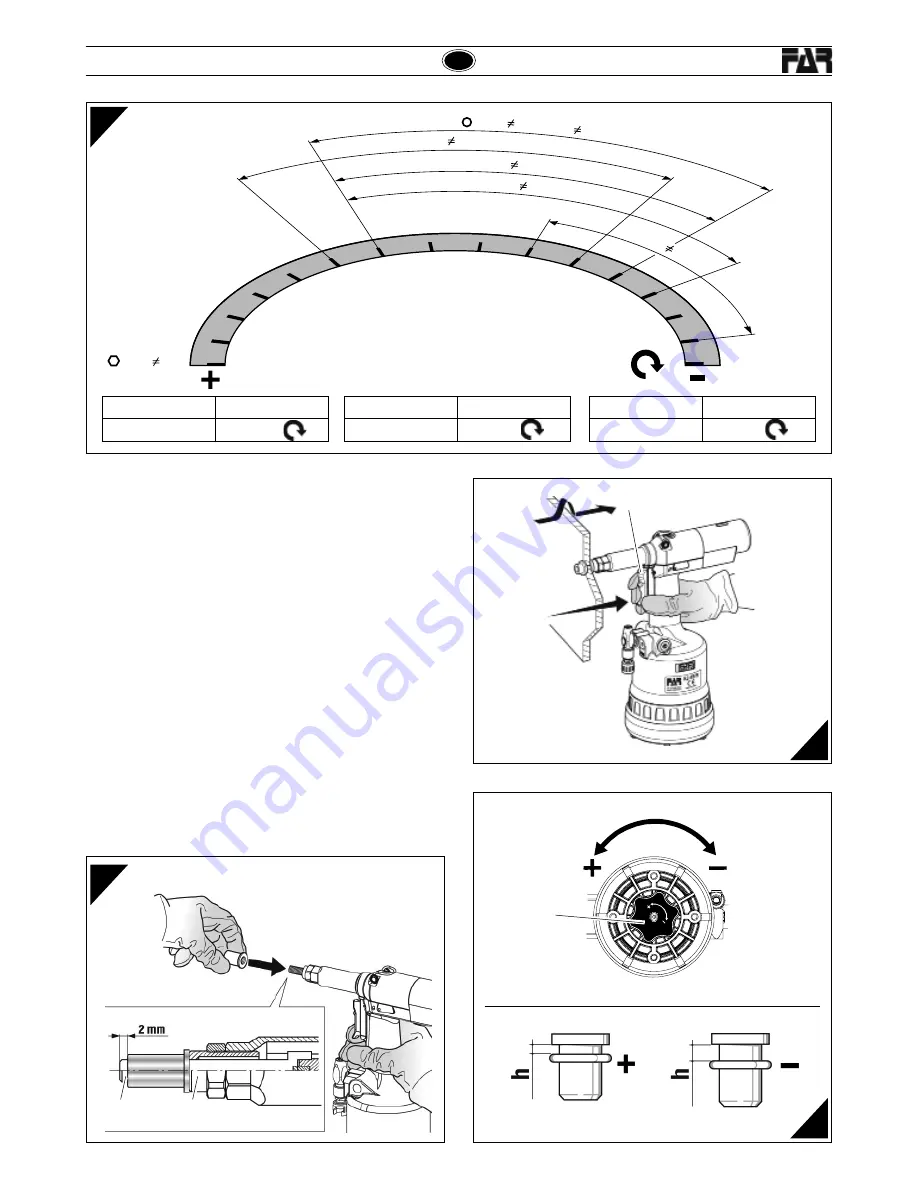

PLACING OF THE INSERT

(fig.

f4-f5-f6

)

Check that the threaded tie rod (

A

) and head (

B

) couple

assembled on the riveting tool is suitable to the size of the

insert to be used.

Adjust the stroke as indicated (fig.

f2-f3

).

Introduce the insert on the tie rod (

A

) and push slightly on it

as indicated in figure

f4

, so as to make it clamp automatically

on the threaded tie rod. Make sure that the insert head touches

the head (

B

) checking that the tie rod (

A

) comes out of 2mm

from the insert.

In case of further adjustments of the tie rod (

A

) follow the

instructions of page 18.

It is now possible to place the insert pushing the button (

D

)

(

fig.f5

) until the insert is completely pulled, and push the

button (

P

) to release the tie rod (fig.

f7

).

For a correct placing and right working of the machine, the

inserts to be used should be properly cleaned.

Note:

According to the desired clamping, carry out other

adjustments of the riveting tool stroke, rotating the knob

(

M

) (fig.

f2-f3-f6

), if necessary.

Insuffi cient deformation =

the insert could rotate inside the

housing compromising its use and resistance.

Excessive deformation =

possible damages of the insert

and tie rod (

A

) with eventual breaks of both components.

D

M

f5

f4

f6

B

A