13

GB

Revisione - 00

Date 04-2017

KJ 70-A

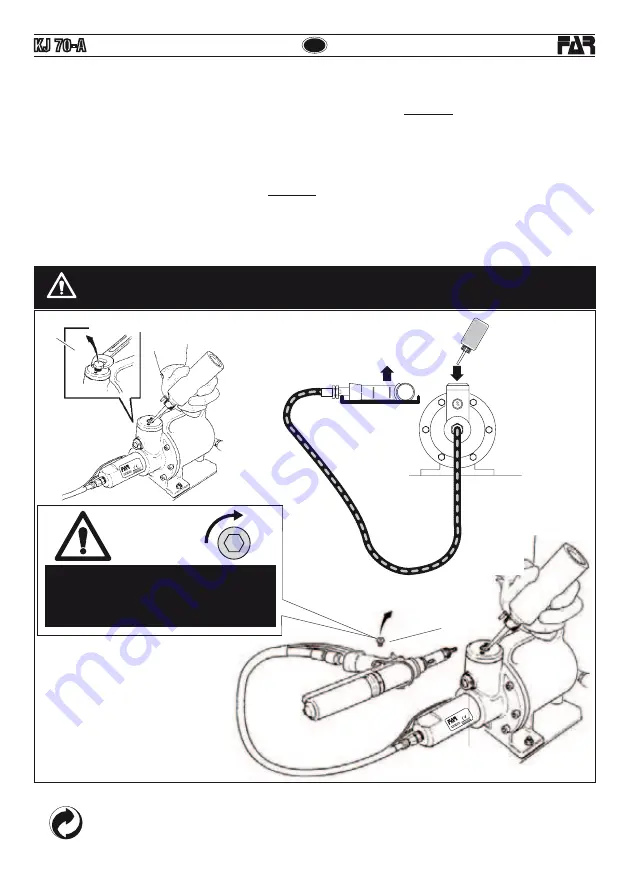

TOPPING UP THE OIL-DYNAMIC CIRCUIT

Verify periodically that the oil level does not go below 3/4 of the limit indicated by the proper indicator (

B

). Whether you need to top up

the circuit, remove the plug (

A

) by means of a 17-mm wrench, then pour hydraulic oil,

HLP 32 cSt

, until it reaches the border of the

threaded hole.

WARNING!

If you fail to perform this operation, you will note power loss that will lead to jeopardise the proper working of the tool.

Therefore, you need to get rid of the air from the tool and restore the exact oil level in the oil-dynamic circuit.

Proceed as follows: put the riveting gun inside a container, in order to avoid loosing oil, and put the upper side of the booster on the same

level of the gun/and lay the feed hoses as the picture shows. Remove the oil screw cap (

A

) and the service plug (

C

) by using a 17-mm

wrench and a 5-mm allen wrench respectively. Pour oil

HLP 32 cSt

until it flows from the hole, without plug (

C

), completely free from

air bubbles. When the operation has been carried out, replace the plug (

C

) and make sure that oil has reached the border of the threaded

hole. Screw the screw cap (

A

) and clean carefully the riveting tool from overflowed oil. It is very important to apply carefully to the

instructions and use always gloves when you handle the tool. Overflowed oil, during the topping, must be collected in proper containers

and delivered afterwards, to specialized waste oil getthering company. Do not smash or cut the connecting hoses between gun and booster.

WARNING! Before disconnecting the compressed air hose, make sure that it is not under pressure!

We recommend to use oil HLP 32 cSt or similars.

DISPOSAL OF THE RIVETING TOOL

Follow the prescriptions of the national laws for disposing of the riveting tool.

After disconnecting the tool from the pneumatic system, disassemble and split all the components according

to the material: steel, aluminium, plastic material, etc.

Then proceed to scrap the materials in accordance with current laws.

A

ch.17mm

WARNING:

Make sure that the oil filler cap

(

A

) is tightened at a torque corresponding to

min. 3.69 ÷ Max. 5.90 ftlb.

min. 3.69 ftlb

Max. 5.90 ftlb

C

B

KJ 70-A

KJ

70-A