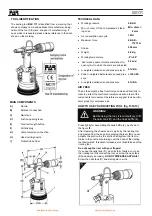

MAINTENACE AND CHANGE OF SIZE (fig. f3-f4-f5-f6)

The extended utilization of the riveting tool can cause the slip-

ping of the clamps on the nail due to the deposited impurities.

For this reason, it is necessary to lubricate the clamps after

having cleaned them. However, if clamps are worn out and as

a consequence their working is jeopardized, replace them.

First remove the head which carries the nozzle (

H

), by means

of a standard spanner of 27 mm. Then, by using two spanners

of 18 mm and 14 mm, remove the chuck (

M

) and extract the

clamps (

N

).

The riveting tool is supplied, besides the nozzle series for FAR

rivets, with a series of accessories for using the rivets type

FARBOLT, MONOBOLT®

and

MAGNA-LOK®

, respectively

of Ø 7.4 (3/16”) and Ø 6.4 (1/4”). For operating with these riv-

ets you have to replace the nozzles, the clamps and the cone

holding clamps.

When replacing the nozzle (

A

), we recommend to use a12-

mm standard spanner and fit the removed nozzle in the proper

housing located on the bottom of your riveting tool, in order to

avoid losing the nozzle.

Follow the prescriptions of the national laws for

disposing of the riveting tool.

After disconnecting the tool from the pneumatic

system, disassemble and split all the compo-

nents according to the material: steel, aluminium,

plastic material, etc.

Then proceed to scrap the materials in accord-

ance with current laws.

DISPOSAL OF THE RIVETING TOOL

Disconnect air feed when performing those

operations.