15

GB

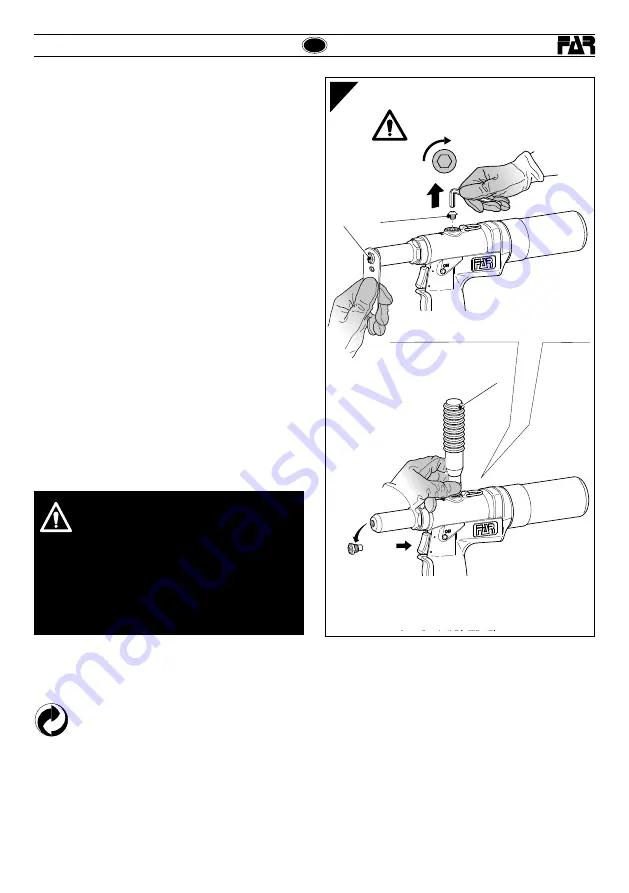

TOPPING UP OIL IN THE HYDRAULIC CIRCUIT (

pic.

f19)

Topping up the oil in the hydraulic circuit is necessary after a long

period of work, when there is a reduction of the riveter stroke.

Then proceed as follows: riveting tool on standby but fed and in

a vertical position, remove the cap (

A

) using the allen wrench 4

mm., remove also the nozzle (

L

) with the provided key. When

doing this operation use extreme caution to prevent oil spills.

Screw the oil container (

Z

), previously filled with commercial

hydraulic oil

HLP 32 cSt

, into the place of the cap (

A

).

By keeping the riveting tool vertically, press the trigger several

times until the riveter ends to make bubbles from the oil container

(

Z

). It means that the oil filling has been fully achieved.

With the riveter still vertical and fed, unscrew the oil container

(

Z

) and then proceed by placing the cap (

A

).

WARNING:

it is very important to follow the about mentioned

instructions and use gloves and protection glasses or protective

visors. If you need to empty fully the hydraulic circuit, you must

put the oil in a suitable container and contact a Company that

is authorized to discharge any waste.

f19

ATTENTION!

Before disconnecting the compressed air hose,

make sure that it is not under pressure!

ATTENTION:

Make sure that the oil filler cap (

A

)

is tightened at a torque corresponding to

min. 5

Nm ÷ Max. 8 Nm.

We recommend to use oil

HLP 32 cSt

or similars.

DISPOSAL OF THE RIVETING TOOL

Follow the prescriptions of the national laws for disposing of the riveting tool.

After disconnecting the tool from the pneumatic system, disassemble and split all the components according to

the material: steel, aluminium, plastic material, etc.

Then proceed to scrap the materials in accordance with current laws.

A

Z

L

min. 5 Nm

MAX 8 Nm

RAC 181

RAC 181

sales@air-allied.com.au

Air & Allied Sales (Pacific) Pty Ltd

www.air-allied.com.au