2

OPERATION

When the 8840/8839 (8840 or 8839) is operating, a sample of air is drawn

from the duct and passed through the sampling chamber by means of the

inlet sampling tube. The air sample passes through the smoke detector

mounted in the duct housing and is exhausted back into the duct through

the outlet sampling tube.

MOUNTING THE AIR DUCT HOUSING

Location on Duct System

Locate the air duct detector in the main supply duct, downstream from the

filters and positioned so as to operate reliably in case of smoke in any part

of the air stream. In instances where filters are capable of removing

smoke, install detectors both upstream and downstream from the filters.

The air duct detectors use sampling tubes which monitor the full width of

an air duct to overcome the limitations of spot-type smoke and heat detec-

tors in the duct. However, since stratification can occur in the air stream

after a long duct run, locate the detector after bends or inlets which create

turbulence, and hence, a more homogeneous mixture of air. The detector

should, when possible, be located a minimum of six duct-widths downstream

from the source of the turbulence (See Figure 1). A 12 inch by 12 inch ac-

cess hole should be cut in the duct adjacent to the detector to permit

checking and cleaning of the sampling tubes, if necessary.

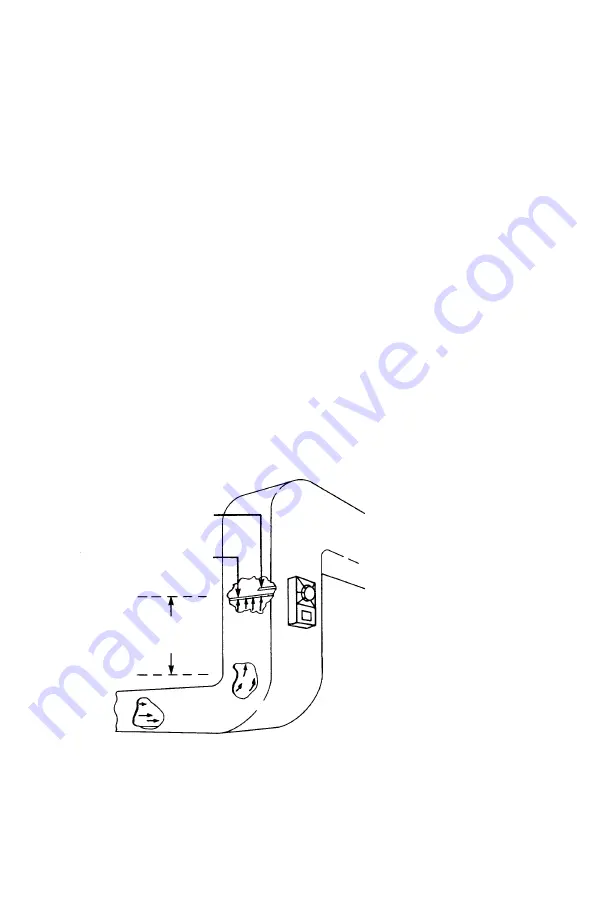

Figure 1

Typical Mounting of Duct

OUTLET

SAMPLING TUBE

INLET

SAMPLING TUBE

AT LEAST

SIX DUCT

WIDTHS

Locate the air duct detector in the air handling system, as shown in Figure

2 and in conformance with NFPA Pamphlet No. 90A, Air Conditioning

and Ventilating System and with NFPA 72 Detectors. (Both publications

are available from the National Fire Protection Association, Batterymarch

firealarmresources.com