3

LW-401 Operation, Installation, and Maintenance Manual

LW-401

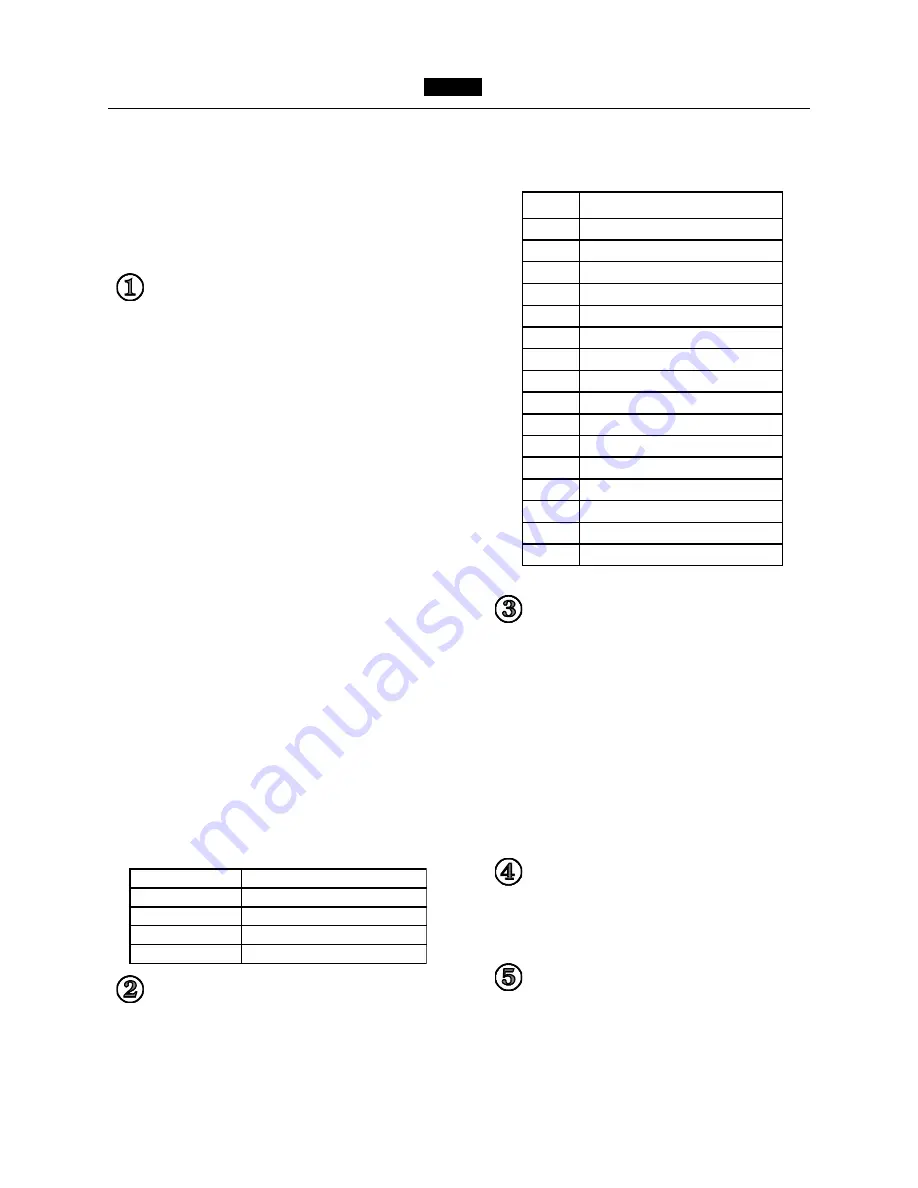

CODE

DESCRIPTION

1

AC power fail

2

NAC 1 trouble

3

NAC 2 trouble

4

Ground fault

5

Municipal tie fault

6

Battery fault

7

System Configuration fault

8

Auxiliary port fault

9

Outputs bypassed

0

Hardware failure

E

Enter password

A

Password accepted

F

Password fail

P

Program mode

t

Test mode

L

Leave Program/Test mode

The Function Keys

The ACK key is used to acknowledge alarms,

troubles, and supervisory conditions. In general

the LEDs change from pulsing to steady to

indicate that the condition was acknowledged.

The SILENCE key silences the notification

appliance circuits that are configured as

silenceable. Pressing the SILENCE key a

second time causes the NACs to re-sound.

The RESET key resets the LW-401 and all of

the smoke detectors.

The DRILL key activates all of the notification

appliance circuits.

The yellow zone status LEDs indicate

a trouble or supervisory condition existing on a

particular input. Pulsing indicates the condition

was not acknowledged; on steady indicates it

was acknowledged.

The red zone status LEDs provide an

indication of the status of a particular zone.

Pulsing indicates an alarm condition in that

zone. When the alarm is acknowledged, the

LED remains on steady until the panel is reset.

FRONT PANEL FUNCTIONS

The front panel of the LW-401 is comprised

of a seven segment display, function keys,

and LEDs. Their functions are described

below (Refer to Figure 2):

The LEDs

The green Power LED remains on steady when

AC power is connected and pulses when the unit

is operating from batteries.

The red Alarm LED pulses when an alarm is

detected until it is acknowledged. Then it remains

on steady until the alarm condition is reset.

The yellow Supervisory LED pulses when a

supervisory condition is detected until it is ac-

knowledged. Then it remains on steady until the

supervisory condition is reset. Note that the

pulsing rates of the trouble and supervisory

conditions are different.

The yellow Trouble LED pulses when a trouble

condition is detected until it is acknowledged.

Then it remains on steady until the trouble

condition is reset. Note that the pulsing rates of

the trouble and supervisory conditions are

different.

The yellow Bypass/Alarm Silence LED is on

steady when a zone in the system is bypassed

and it pulses when a notification circuit is si-

lenced. When an initiating device zone is by-

passed, the appropriate yellow zone trouble LED

is on.

The Test/Program LED is on steady when the

Test mode is selected and it pulses when the

Program mode is selected.

The Sounder

CONDITION

RATE OF PULSATION

SYSTEM ALARM

Sounds steady

TROUBLE

Pulses at 50% duty cycle

SUPERVISORY

Pulses at 25% duty cycle

CPU FAILURE

Pulses once every 2 seconds

The seven segment display indicates the

various system troubles and the programming and

test modes. The numbers and symbols that appear

on this display are described in the following chart.