FOR RESTRICTED USE only

Fargo Electronics, Inc.

DTC550 Direct to Card Printer/Encoder User Guide (Rev. 2.8)

4-5

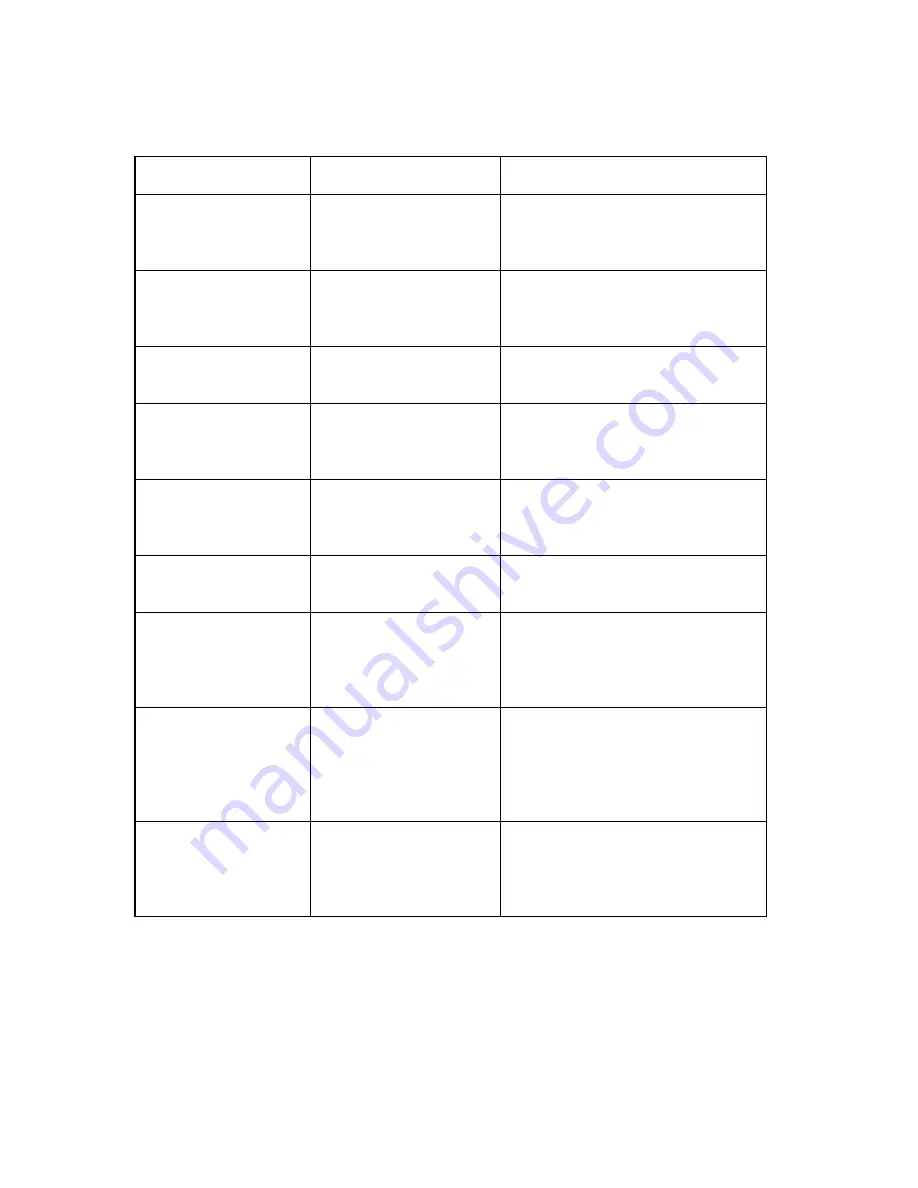

Troubleshooting the LCD Messages (continued)

LCD Message

Cause

Solution

E-CARD ENCODER

STARTUP ERROR

A problem was

detected during Printer

start-up.

If this problem persists, call for

technical assistance.

E-CARD STARTUP

ERROR

A problem was

detected during Printer

start-up.

If this problem persists, call for

technical assistance.

EEPROM

CORRUPTION

EEPROM restored with

factory default values.

No action needs to be taken.

EEPROM READ

FAILURE

EEPROM read failed.

Cycle power and try again. If this

problem persists, call for technical

assistance.

EEPROM REPAIR

FAILED

EEPROM is corrupted.

Repair attempt failed.

Cycle power and try again. If this

problem persists, call for technical

assistance.

EEPROM

RESTORED

Part of EEPROM was

corrupted.

Repaired successfully.

EJECTING USED

CARD

The system Firmware

has detected a card

already in the Printer.

This card has been ejected

however it may contain encoded

data and therefore should be

disposed of properly.

ERR CHK LAM

MATERIAL

See the next column.

Install a new Lamination roll and

press

RESUME

to continue or

CANCEL

to abort. If the problem

persists, call for technical

assistance.

ERR CHK LAM

MATERIAL

See the next column.

Install a new film roll and press

RESUME

to continue or

CANCEL

to abort. If the problem persists,

call for technical assistance.