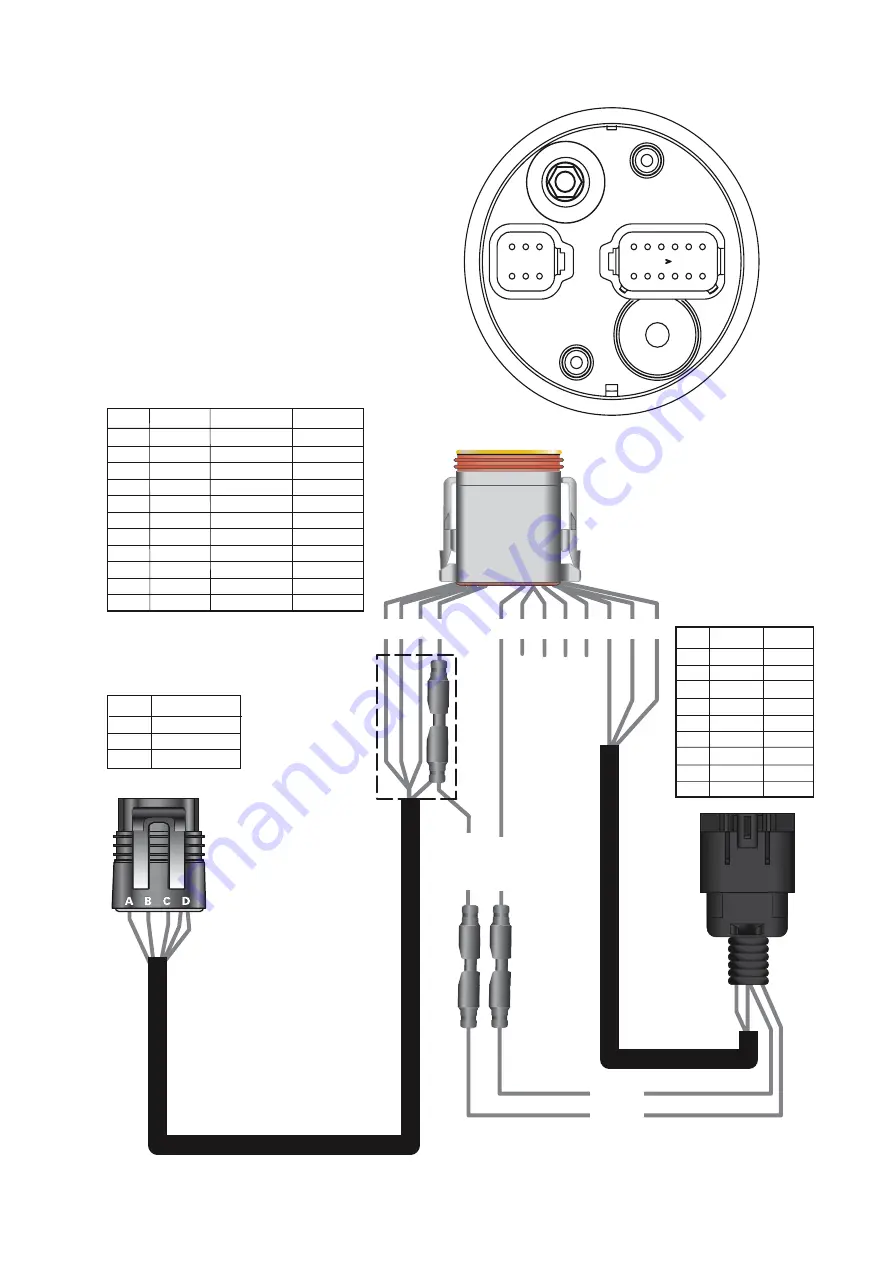

MG2000 Tachometer

6

5

4

3

2

1

7

8

9

10

11

12

1

2

3

6

5

4

SmartCraft

Harness HN0565

SmartCraft

Tachometer Cable

(To connect from the SmartCraft

harness to the junction box.)

4- pin connector

12- pin connector

Pin A Red

Pin B White

Pin C Green

Pin D Black & Sheild

Pin 1 Red

Faria Bus

+8.4 VDC

Pin 2 White

Faria Bus

AY

Pin 3 Green

Faria Bus

BZ

Pin 4 Black

Faria Bus

Ground

Pin 5 Violet

Ignition(Wake)

Pin 6 Not Used

Pin 7 Not Used

Pin 8 Not Used

Pin 9 Not Used

Pin 10 Black

Not Used

Pin 11 Red

CAN 1 +

Pin 12 White

CAN 1 -

SmartCraft Cable

Pin A Not Used

Pin B Black

Ground

Pin C Not Used

Pin D Not Used

Pin E Not Used

Pin F Violet

(Wake Up)

Pin G Not Used

Pin H Not Used

Pin J Red

CAN 1+

Pin K White

CAN 1 -

1 2 3 4 5 6 7 8 9 10 11 12

Wire Jacket

Heat

Shrink

�ubing

V

iolet

Violet

Black

Black

Not Used

Not Used

Not Used

Not Used

HN0565 r.B ecr 5629 8/05

Page 50

All manuals and user guides at all-guides.com

all-guides.com

Summary of Contents for SmartCraft MG2000

Page 8: ...Page 2 This page left blank intentionally All manuals and user guides at all guides com ...

Page 20: ...Page 14 This page left blank intentionally All manuals and user guides at all guides com ...

Page 45: ...Page 39 This page left blank intentionally All manuals and user guides at all guides com ...

Page 50: ...Page 44 This page left blank intentionally All manuals and user guides at all guides com ...