Maintenance - Teleswing

42

SERVICE SCHEDULE

Maintenance Intervals

Maintenance work must be done at regular intervals. Failure to do so will result in excessive wear and

early failures. The service schedule is a guide for correct maintenance of the equipment.

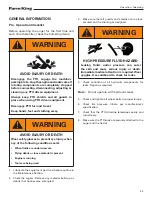

WARNING

Instructions are necessary before operating or servicing equipment. Read and understand the

Operator and Parts Manual and safety signs (decals) on equipment. Follow warnings and instructions

in the manuals when making repairs, adjustments or servicing. Check for correct function after

adjustments, repairs or service. Untrained operators and failure to follow instructions can cause

injury or death.

Item

DESCRIPTION

SERVICE PROCEDURES

Check

Clean

Lube

Change

Cover

Daily Maintenance (or every 8 hours)

1

Bushing - Hopper Feed Screw

•

2

Bushing - Hopper Jack Shaft

•

3

Bushing - Transition Screw

•

Every 80 Hours

4

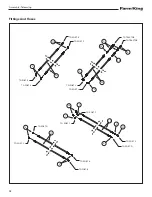

U-Joint - Lower Hopper

•

5

U-Joint - Upper Hopper

•

6

U-Joint - Collector

•

7

Hopper Chain Drive

•

•

8

Spline Shaft

•

•

•

9

Chain Box Chain Drive

•

•

Every 200 Hours

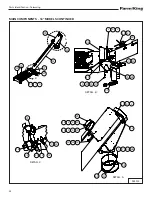

10

Bearings - Hopper Feed Screw

•

11

Bearings - Jack Shaft

•

12

Bearings - Chain Box

•

13

Gearbox - Collector (Oil SAE 90)

•

•

Summary of Contents for 13''

Page 1: ...092018 F2426 OPERATOR AND PARTS MANUAL TELESWING AUGER Model 13 16 ...

Page 2: ......

Page 4: ... Teleswing 2 ...

Page 6: ...Warranty Registration Form Teleswing 4 ...

Page 8: ...Introduction Teleswing 6 ...

Page 12: ...Safety Teleswing 10 ...

Page 17: ...Safety Teleswing 15 ...

Page 22: ...Safety Teleswing 20 ...

Page 24: ...Assembly Teleswing 22 ...

Page 32: ...Assembly Teleswing 30 ...

Page 34: ...Operation Teleswing 32 ...

Page 40: ...Operation Teleswing 38 ...

Page 42: ...Maintenance Teleswing 40 ...

Page 48: ...Maintenance Teleswing 46 ...

Page 66: ...Parts Identification Teleswing 64 ROLLER FLANGE 5 2 1 3 4 6 3 7 934701 ...

Page 88: ...Parts Identification Teleswing 86 ...

Page 90: ...Specifications Teleswing 88 ...

Page 96: ...Warranty Teleswing 94 ...

Page 99: ......