DO NOT open the lid of the

eductor while in operation as

splashing of chemical may occur.

CAUTION

CAUTION

AGRICULTURAL CHEMICALS

CAN BE DANGEROUS.

IMPROPER SELECTION OR

USE CAN INJURE PERSONS,

ANIMALS, PLANTS, SOILS

OR OTHER PROPERTY.

TO AVOID INJURY

1. SELECT THE RIGHT

CHEMICAL FOR THE JOB.

2. HANDLE AND APPLY IT

WITH CARE. FOLLOW

INSTRUCTIONS ISSUED

BY THE CHEMICAL

MANUFACTURER.

002438

Fill Solution Tank, Utilizing Optional Eductor

Load the solution tank using the optional eductor via

the following steps:

1. Close all valves.

2. Remove solution quick fill cap and connect load

hose.

3. Open solution quick fill valve and solution tank

main valve.

4. Open valve on loading reservoir (i.e. nurse tank)

5. Fill eductor with desired amount of chemical to be

pulled into the solution tank. CLOSE Eductor Lid.

6. Start the remote transfer pump.

7. Once there is a steady flow rate from the nurse

tank to the solution tank, open the eductor valve

and close the solution quick fill valve. Once there

is a steady flow rate again, open the eductor tank

valve for 15-30 seconds.

8. Close the eductor tank valve and verify the chemi-

cal has been completely removed from the educ-

tor tank. Repeat steps 7 and 8 if chemical remains

in the eductor tank.

9. Run remote transfer pump until the desired

amount of solution is transferred into the sprayer.

10. Close valves on the loading reservoir.

11. Close solution quick fill valve and the eductor

valve on the sprayer.

12. Remove load line and replace cap on sprayer

quick fill.

Operation Instructions - Section B

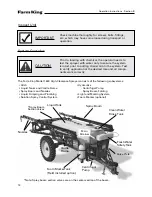

Solution Quick Fill Connection

Eductor Lid

Left Side View Eductor

(Optional)

Solution Quick Fill and Eductor

Plumbing (Optional)

Left Under Frame View

Eductor Inlet Valve

(Closed Position)

Solution Quick Fill

(Closed Position)

Eductor Outlet Valve

(Closed Position)

Eductor Tank Valve

(Closed Position)

19

Summary of Contents for 1600

Page 1: ...Operator and Parts Manual 1600 High Clearance Sprayer 04 2010 SXL 26030 ...

Page 5: ...Safety Instruction Section A 5 ...

Page 11: ...Safety Decal Placement Safety Instructions Section A 11 ...

Page 12: ...Notes Safety Instructions Section A 12 ...

Page 13: ...Operation Instructions Section B 13 ...

Page 29: ...Connection Startup Section C 29 ...

Page 38: ...Connection Startup Section C Notes 38 ...

Page 39: ...Storage Section D 39 ...

Page 43: ...Maintenance Service Troubleshooting Section E 43 ...

Page 50: ...Maintenance Service Troubleshooting Section E Notes 50 ...

Page 51: ...Parts Schematics Section F 51 ...

Page 52: ...19 Description Decal Placement Parts Schematics Section F 52 ...

Page 54: ...Description Trailer Sprayer Light Kit Assembly Parts Schematics Section F 54 ...

Page 56: ...Description Frame Assembly Parts Schematics Section F 56 ...

Page 58: ...Description Drawbar Assembly Parts Schematics Section F 58 ...

Page 60: ...Description 10 Bolt Adjustable Axle Assembly Parts Schematics Section F 60 ...

Page 62: ...Description Cradle Assembly Parts Schematics Section F 62 ...

Page 64: ...Description Tank Spreader and Sight Gauge Parts Schematics Section F 64 ...

Page 66: ...Parts Schematics Section F Description Fold Over the Top Boom Center Section Assembly 66 ...

Page 68: ...Description Fold Boom Primary Section Assembly Parts Schematics Section F 68 ...

Page 70: ...Description Fold Boom Secondary Breakaway Assembly Parts Schematics Section F 70 ...

Page 72: ...Parts Schematics Section F Notes 72 ...

Page 74: ...Description Sprayer Hydraulic Routing Parts Schematics Section F 74 ...

Page 76: ...Description Fold Over The Top Boom Hydraulic Valve Breakdown Parts Schematics Section F 76 ...

Page 79: ...Parts Schematics Section F Notes 79 ...

Page 82: ...Description Spray Boom Cylinder Assembly Parts Schematics Section F 82 ...

Page 84: ...Description Boom Rephasing Cylinder Assembly Parts Schematics Section F 84 ...

Page 86: ...Description Pump Plumbing Parts Schematics Section F 86 ...

Page 88: ...Parts Schematics Section F Description Tank Plumbing 88 ...

Page 90: ...Description Raven Control Plumbing Parts Schematics Section F 90 ...

Page 93: ...Parts Schematics Section F Notes 93 ...

Page 94: ...Description Valve Mounting 94 Parts Schematics Section F ...

Page 96: ...Description Fold Over the Top Boom Plumbing Kit Parts Schematics Section F 96 ...

Page 98: ...Description Manual Fence Row Plumbing Parts Schematics Section F 98 ...

Page 100: ...Description Eductor Assembly Parts Schematics Section F 100 ...

Page 103: ...Warranty Section G 103 ...