Safety Instructions for Operation

1. DO NOT ALLOW ANYONE TO OPERATE THIS FARM KING SPRAYER UNTIL HE OR SHE HAS

READ THIS MANUAL AND IS COMPLETELY FAMILIAR WITH ALL SAFETY AND OPERATION

PROCEDURES.

Safety Instructions - Section A

DANGER

Always wear protective clothing, goggles, respirator

and gloves when handling chemicals.

2. If any safety device on the sprayer itself is not functioning properly, DO NOT use the sprayer.

Remove it from service until it has been properly repaired by a qualified service technician.

3. Do not allow the following people to operate or repair this equipment.

• Children

• Irresponsible persons

• People under the influence of alcohol, medications or other drugs that can cause drowsiness

or impaired judgement.

• Persons unfamiliar with equipment or people who are careless or unfamiliar with safe

operating procedures.

WARNING

Observe the IMPORTANT SAFETY INSTRUCTIONS

listed below at all times! THE BEST KIND OF SAFETY IS

A CAREFUL OPERATOR.

CAUTION

Always wear protective clothing, goggles, respirator

and gloves when handling chemicals.

WARNING

Observe all Federal and State EPA regulations and all

Local, State and Federal codes and / or laws regarding

licensing, handling, storage, transportation, application

and waste disposal of chemicals.

7

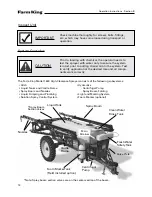

Summary of Contents for 1600

Page 1: ...Operator and Parts Manual 1600 High Clearance Sprayer 04 2010 SXL 26030 ...

Page 5: ...Safety Instruction Section A 5 ...

Page 11: ...Safety Decal Placement Safety Instructions Section A 11 ...

Page 12: ...Notes Safety Instructions Section A 12 ...

Page 13: ...Operation Instructions Section B 13 ...

Page 29: ...Connection Startup Section C 29 ...

Page 38: ...Connection Startup Section C Notes 38 ...

Page 39: ...Storage Section D 39 ...

Page 43: ...Maintenance Service Troubleshooting Section E 43 ...

Page 50: ...Maintenance Service Troubleshooting Section E Notes 50 ...

Page 51: ...Parts Schematics Section F 51 ...

Page 52: ...19 Description Decal Placement Parts Schematics Section F 52 ...

Page 54: ...Description Trailer Sprayer Light Kit Assembly Parts Schematics Section F 54 ...

Page 56: ...Description Frame Assembly Parts Schematics Section F 56 ...

Page 58: ...Description Drawbar Assembly Parts Schematics Section F 58 ...

Page 60: ...Description 10 Bolt Adjustable Axle Assembly Parts Schematics Section F 60 ...

Page 62: ...Description Cradle Assembly Parts Schematics Section F 62 ...

Page 64: ...Description Tank Spreader and Sight Gauge Parts Schematics Section F 64 ...

Page 66: ...Parts Schematics Section F Description Fold Over the Top Boom Center Section Assembly 66 ...

Page 68: ...Description Fold Boom Primary Section Assembly Parts Schematics Section F 68 ...

Page 70: ...Description Fold Boom Secondary Breakaway Assembly Parts Schematics Section F 70 ...

Page 72: ...Parts Schematics Section F Notes 72 ...

Page 74: ...Description Sprayer Hydraulic Routing Parts Schematics Section F 74 ...

Page 76: ...Description Fold Over The Top Boom Hydraulic Valve Breakdown Parts Schematics Section F 76 ...

Page 79: ...Parts Schematics Section F Notes 79 ...

Page 82: ...Description Spray Boom Cylinder Assembly Parts Schematics Section F 82 ...

Page 84: ...Description Boom Rephasing Cylinder Assembly Parts Schematics Section F 84 ...

Page 86: ...Description Pump Plumbing Parts Schematics Section F 86 ...

Page 88: ...Parts Schematics Section F Description Tank Plumbing 88 ...

Page 90: ...Description Raven Control Plumbing Parts Schematics Section F 90 ...

Page 93: ...Parts Schematics Section F Notes 93 ...

Page 94: ...Description Valve Mounting 94 Parts Schematics Section F ...

Page 96: ...Description Fold Over the Top Boom Plumbing Kit Parts Schematics Section F 96 ...

Page 98: ...Description Manual Fence Row Plumbing Parts Schematics Section F 98 ...

Page 100: ...Description Eductor Assembly Parts Schematics Section F 100 ...

Page 103: ...Warranty Section G 103 ...