9

Assembly - 5010, 6010 & 6610 Snowblower

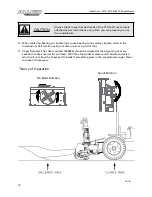

Assembly Instructions

1. Mount the discharge spout (816667) using the spout spacers and spout clamps (816619 &

815586). Bolt the spout ring on snowblower. Lubricate the spout ring and clamp.

NOTE: A hydraulic cylinder and hose kit to control the spout deflector is available as an option.

2. Hitch Assembly: With right and left hitch tubes (907127 & 907128) turned as shown in drawing,

slide them into the sleeve welded to the main body. These tubes are adjustable to four different

positions. The correct position for each individual tractor will be determined when mounting

the snowblower on the tractor. These tubes are connected to the snowblower with a 3/4" x

3-1/4" (19 x 83 mm) pin (965624) and a hair pin clip (12779). Bolt the left (815218) and the right

(815219) hitch arms to the outside of the clevises on the hitch tubes using the lift pins (965809).

NOTE: Pins should be turned to the outside. Do not tighten any hardware until assembly is

complete. Join the top of the hitch arms by bolting a 1" O.D. x 2-1/4" (25 x 57 mm) spacer

(906770) between the top plates using a 3/4" x 4" (19 x 102 mm) bolt and lock nut through the

lower outside holes. Bolt the hitch top bar (907139) between the same plates using the same

bolt through the welded tube on the bar. Use the inside holes on the top plates for the top bar.

The other end of the hitch top bar bolts to the top of the blower fan housing with a 1/2" x 1-3/4"

(13 x 44 mm) hex bolt, lock washer and hex nut. Use the same hole position as the hitch tubes.

Tighten all hardware.

A Category 1 top link pin (965807) is fitted in the top holes of the hitch arm plates. This pin is

used for standard three-point hitch only. The bushing in the lower holes is used for the Quick

Hitch.

3. Hand Crank Assembly: (Standard)

- Bolt the crank mounting bracket (965634) to the top of the hitch using 3/8" x 1-1/4" (10 x 32

mm) hex bolts, lock washers and hex nuts.

- Insert the crank handle (906667) through the mount and through the bracket welded to

the main housing. Lock the crank in place using a washer and roll pin on each side of the

bracket.

- Thread the cable (965616) through the hole in the crank tube to even lengths and wrap

around the tube to each side of the hole four turns in opposite directions.

- With the spout turned forward, fasten the cable to the bracket welded to the bottom of the

spout using a 1/4" (6 mm) cable clamp (961658).

4. Hydraulic Control Assembly: (Option)

- Bolt the hydraulic swivel assembly (965626) to the back of the fan housing on the left side

using 1/2" x 1-1/4" (13 x 32 mm) hex bolts, lock washers and hex nuts.

- Bolt the cylinder mounting bracket (965628) to the back of the fan housing on the right side

using the same size hex bolts.

- Turn the spout forward and the center of the swivel arm in line with the spout center. With

the spout and swivel arm in this position, wrap the cable (965627) around the spout and

clamp to both ends of the swivel arm and to the bracket welded to the bottom of the spout

using 3/16" (5 mm) cable clamps (965806).

- Use a standard 8" (203 mm) stroke cylinder (20-1/4" (51 cm) min., 28-1/4" (72 cm) max. pin

centers).

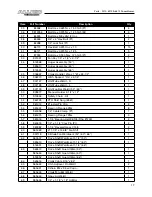

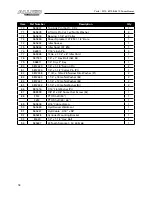

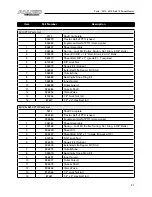

Summary of Contents for ALLIED 5010

Page 1: ...Snowblower Models 5010 6010 6610 OPERATOR AND PARTS MANUAL 032014 FK312...

Page 2: ......

Page 19: ......

Page 20: ...20 Parts 5010 6010 6610 Snowblower PTO Shaft Drawing...

Page 25: ......

Page 29: ......