165

Specifications - High Speed Compact Disc

HYDRAULIC CONNECTION SPECIFICATIONS

O-Ring Fitting (Straight Thread)

Lubricate the O-ring before installing the fitting. Loosen

the jam nut and install the fitting. Tighten the jam nut until

the washer is tight against the surface.

O-ring Face Seal Connection

Table 5

When the fitting is tightened, you can feel when the fitting

is tight to eliminate leakage caused by under or over

torqued fittings. Use petroleum jelly to hold the O-ring in

position until the fittings are assembled.

Flare Fitting

Table 6

Tighten until the nut makes contact with the seat. Use the

chart

to find the correct tightness needed.

NOTE: If the fitting leaks, disconnect and inspect the

seat area for damage.

Port Seal (O-ring Boss) Fitting

Table 7

NOTE: Port seal and nut, washer and O-ring (O-ring

Boss) fittings use the same tightening torque

valve chart.

If a torque wrench cannot be used, use the following

method.

Tighten the nut until it just makes metal to metal contact,

you can feel the resistance.

Tighten the nut with a wrench no more than one hex flat

maximum.

Do not over tighten the port seal fitting.

NOTE: If a torque wrench cannot be used, use the

hex flat tightening method as an approximate

guideline.

NOTE: Port seal fittings are not recommended in all

applications. Use O-ring boss fittings in these

applications.

Tubelines And Hoses

Replace any tubelines that are bent or flattened. They will

restrict flow, which will slow hydraulic action and cause

heat.

Replace hoses which show signs of wear, damage or

weather cracked rubber.

Always use two wrenches when loosening and tightening

hose or tubeline fittings.

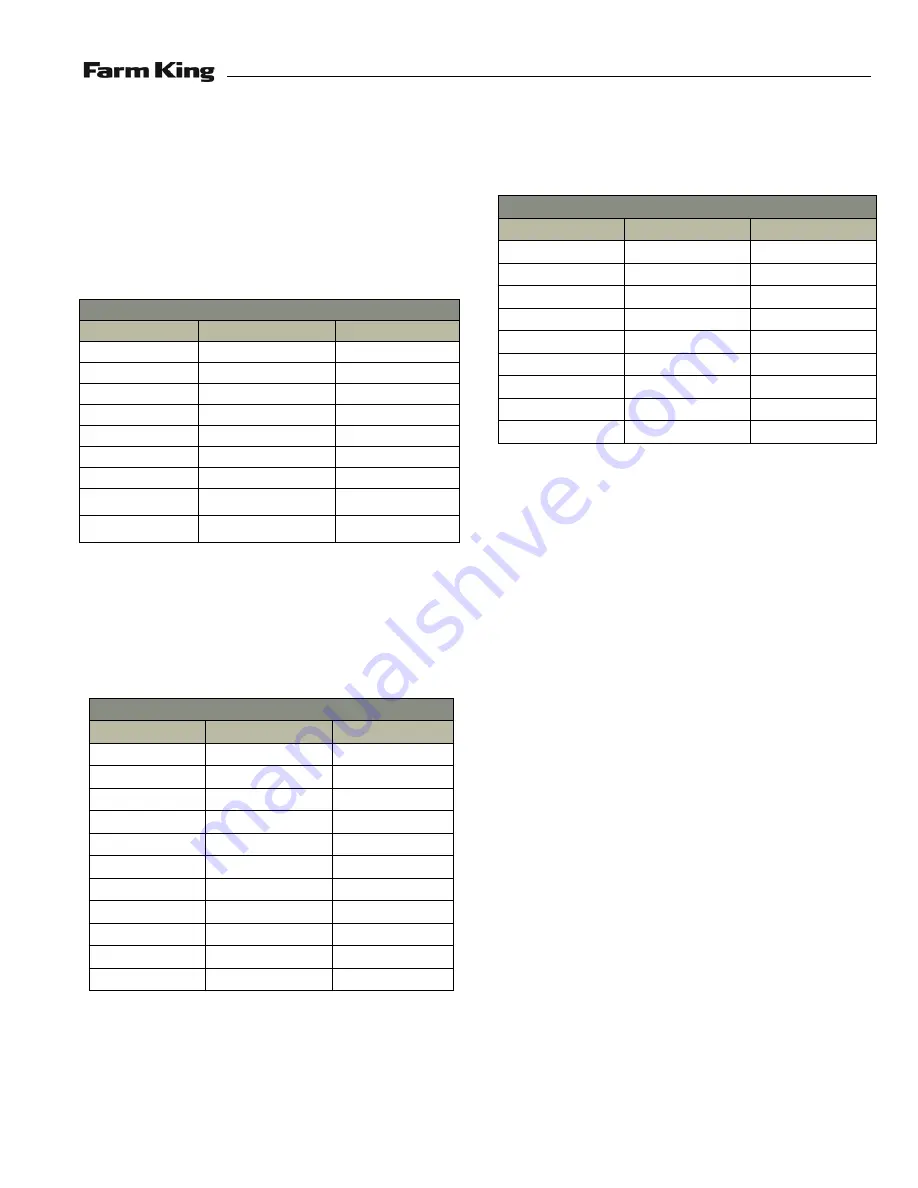

O-ring Face Seal Tightening Torque

Tubeline O.D.

Thread Size

N•m (ft-lb)

1/4"

9/16" - 18

13 (18)

3/8"

11/16" - 16

22 (30)

1/2"

13/16" - 16

40 (54)

5/8"

1" - 14

60 (81)

3/4"

1-3/16" - 12

84 (114)

7/8"

1-3/16" - 12

98 (133)

1"

1-7/16" - 12

118 (160)

1-1/4"

1-11/16" - 12

154 (209)

1-1/2"

2" - 12

163 (221)

Flare Fitting Tightening Torque

Tubeline O.D.

Thread Size

N•m (ft-lb)

1/4"

7/16" - 20

13 (18)

5/16"

1/2" - 20

17 (23)

3/8"

9/16" - 18

22 (30)

1/2"

3/4" - 16

40 (54)

5/8"

7/8" - 14

60 (81)

3/4"

1-1/16" - 12

84 (114)

7/8"

1-3/16" - 12

98 (133)

1"

1-5/16" - 12

118 (160)

1-1/4"

1-5/8" - 12

154 (209)

1-1/2"

1-7/8" - 12

163 (221)

2"

2-1/2" - 12

252 (342)

Port Seal And O-ring Boss Tightening Torque

Tubeline O.D.

Thread Size

N•m (ft-lb)

1/4"

7/16" - 20

13 (18)

3/8"

9/16" - 18

22 (30)

1/2"

3/4" -1 6

40 (54)

5/8"

7/8" - 14

60 (81)

3/4"

1-1/16" - 12

84 (114)

7/8"

1-3/16" - 12

98 (133)

1"

1-5/16" - 12

118 (160)

1-1/8"

1-7/16" - 12

154 (209)

1-1/4"

1-5/8" - 12

163 (221)

Summary of Contents for HS8525

Page 2: ......

Page 4: ...4 Table of Contents High Speed Compact Disc ...

Page 6: ...Warranty Registration High Speed Compact Disc 6 ...

Page 10: ...10 Introduction High Speed Compact Disc ...

Page 14: ...14 Safety High Speed Compact Disc ...

Page 28: ...28 Safety High Speed Compact Disc ...

Page 30: ...30 Assembly High Speed Compact Disc ...

Page 74: ...74 Assembly High Speed Compact Disc ...

Page 76: ...76 Operation High Speed Compact Disc ...

Page 92: ...92 Maintenance High Speed Compact Disc ...

Page 102: ...102 Part Identification High Speed Compact Disc ...

Page 104: ...104 Part Identification High Speed Compact Disc WHEELS TIRES WINGS 3 1 4 5 2 88717299 ...

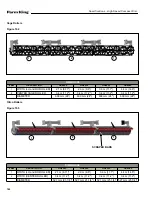

Page 152: ...152 Part Identification High Speed Compact Disc BLADES 2 1 3 88717644 ...

Page 154: ...154 Part Identification High Speed Compact Disc ...

Page 156: ...156 Specifications High Speed Compact Disc ...

Page 166: ...166 Specifications High Speed Compact Disc ...

Page 167: ...167 Warranty High Speed Compact Disc WARRANTY WARRANTY 169 ...

Page 168: ...168 Warranty High Speed Compact Disc ...

Page 171: ......