FarmBoy

®

Agricultural Inter-Cultivator

FB-IC-209P

: +91.80. 22178200

Page 8 of 65

head is in the big hole.

4.

Anticlockwise turn reverse fork axle, and put cable through narrow slot, and make

sure head into big hole of seat.

5.

Turn off Bolt, and hold it tightly. Loose reverse handle until spring in clutch can return

handle, and then locked nut.

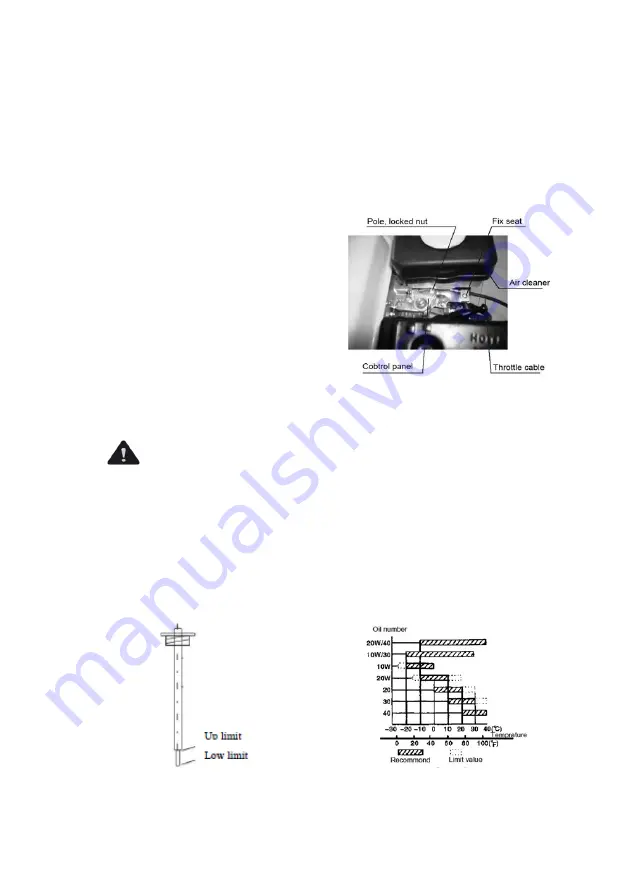

2.3 Adjusting of throttle cable. (Drawing 4)

1.

Turn throttle switch into max.

2.

Put steel wire of throttle cable

through wire seat and fixed seat

which is on control panel.

3.

Tight steel wire, locked screw on

locked seat

4.

Adjust fuel switch some time, until

fuel rod on control panel into max.

OPERATION CHECK

Engine Oil:

CAUTION

1.

Running the engine with low oil level will cause serious engine damage.

a)

Remove the oil filler cap and wipe the dipstick clean.

b)

Insert the dipstick into the oil filler neck but do not screw it in.

c)

If the level is low, fill the recommended oil to the top of the oil filler neck.

2.

Use high-detergent, premium quality 4-stroke engine oil, certified to meet or exceed

automobile manufacturer’s requirement for API Service Classification

3.

Using non-detergent oil or 2-stroke engine oil cou

ld shorten the engine’s service life.

4.

SAE 10W-30 is recommended for general all-temperature use. Other viscosities

shown in the following chart might be used when at the average temperature in your

area is within the indicated range.