Manual

FANTOM 850 PS

24

│

33

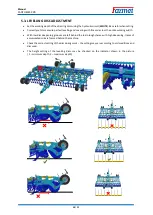

3.4.2.

MACHINE FOLDING PROCEDURE

Tab. 6 – Transport position of the machine

Machine Folding Procedure – Transport Position

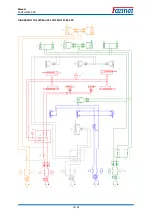

Initial condition: The machine is unfolded and maximally lifted during the headland turn. All closing valves open,

the red circuit switched to frame folding

1

Lift the machine up to the maximum

height using the green circuit.

Eject the axle piston rods (yellow circuit)

into the end position, lift the machine up

to the maximum height.

Fold the machine with the red circuit.

2

Switch the red circuit for securing hook

control. Put all washers on the middle

roller and the tow bars (for work and

transport, height below 4 metres).

Set the side leveling discs to the transport

position.

Secure the side frames with the red

circuit.

With the green circuit, lower the machine

to the washers and

insert the piston rods of

the side rollers to the end position,

i.e. maximum insertion. Transport height

below 4 m and width below 3 m.

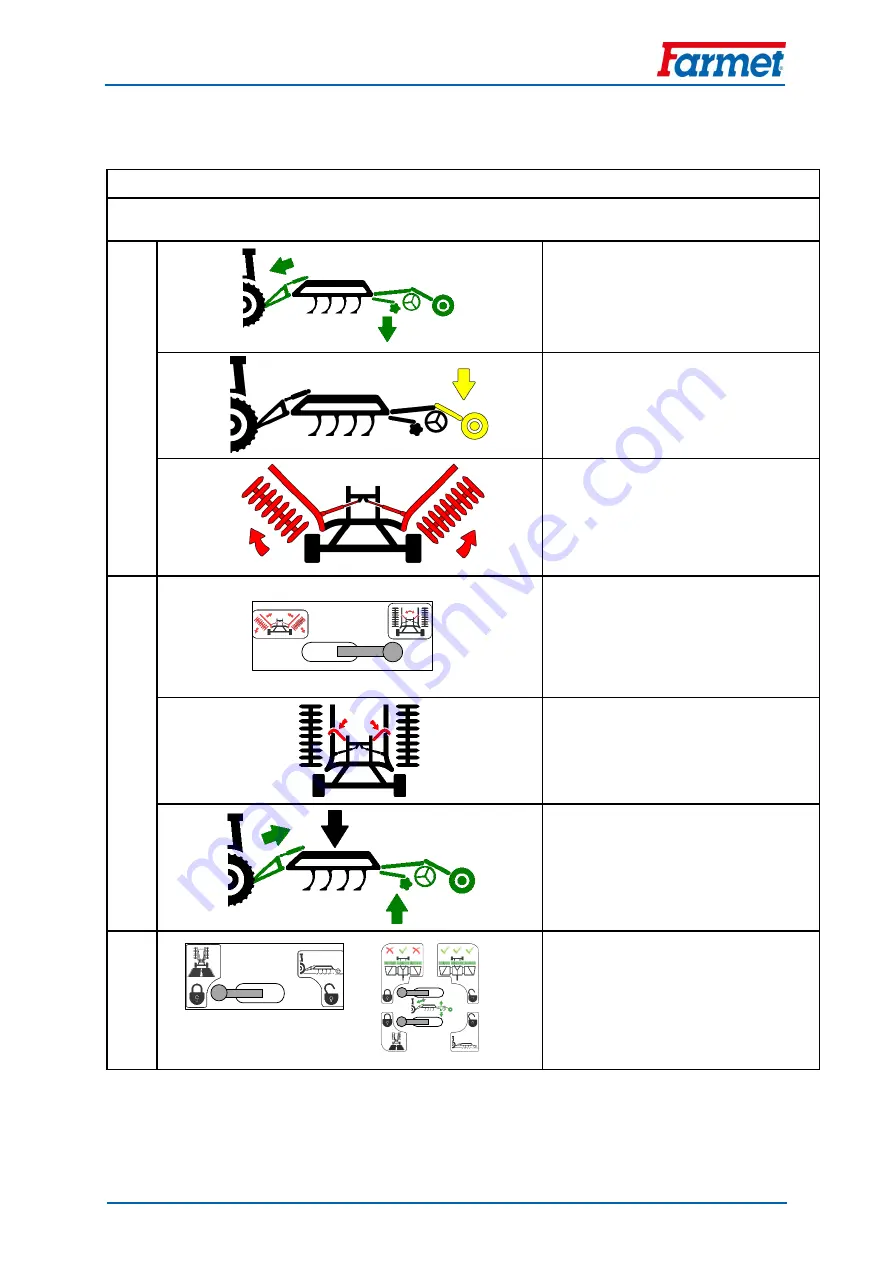

3

Switch both levers of the green circuit and

the circuit closing (red and yellow) lever

for transport to the left (close).