MOUNTING INSTRUCTIONS

JL 601

B // En // 141001MRu

www.normet.fi

Normet Corporation

Ahmolantie 6

FIN --- 74510 PELTOSALMI

FINLAND

Tel. + 358 (0) 17 83 241

Fax. + 358 (0) 17 823 606

12

Page

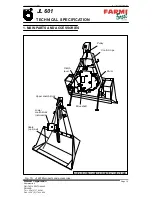

4. MOUNTING INSTRUCTIONS

4.1. MOUNTING TO THE

3--POINT HITCH

The winch can be mounted to the 3---point

linkage of any tractor. Power transmission is

obtained through universal shaft from tractor.

4.2. ASSEMBLY OF THE PTO SHAFT

If the PTO shaft is too long it

may get pressed when the

three point hitch is lifted up.

This may cause damage to the

bearings of the winch or to the

PTO of the tractor. The PTO

shaft must not be too short in

any position. The PTO length

is suitable, if the pipes do not

reach the bottom. PTO is

optional equipment.

Note!

1. Mount the winch to the 3---point hitch of

the tractor.

2. Raise the winch high enough to get the

PTO shaft of the tractor and the winch to a

horizontal level.

3. If you have a shortened PTO shaft

available, put one end into the drive shaft

and check that the distance of the locking

of the other end. Take into account the

additional clearance of approx. 20

mm(0.78”).

4. Fasten the other end of the PTO shaft in its

place and also move the winch sideways

at the same time securing that the axis

does not base.

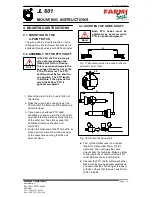

4.3. SHORTEN THE DRIVE SHAFT

Both PTO halves must be

shortened by equal amounts.

PTO is optional equipment.

Note!

A

Fig. 17.Measure A when the drive shafts are

nearest to each other.

A

20

1

2

Fig. 18.Shorten the drive shaft.

D

First cut the thicker cover to a correct

lenght (1). Remember 20mm (0.78”)

clearance. Then cut away the same

amount from the form pipe. Make a similar

shortening to the second half of the PTO

shaft. Remove the burr with the file.

D

Connect the PTO shafts within each other.

Make sure by moving eevator carefully up

and down that the shortening of the axis is

sufficient. Check that the axis have 20mm

(0.78”) latitude.