HF 231

12

Fig 8.Feeder reel speed settings.

D

The speed is suitable when the wood does not push

against the grinding wheel or the feeder reel spikes

do not slow down the feeding of wood.

D

Make sure that you are using clean oil in the

hydraulic system. Dirt in the oil will damage valves

and hydraulic motors.

7.5.EMTYING THE CHIPPER AFTER USE

D

Before stopping the chipper, chip about

∅

80---100

mm wood. Let the blades cut a few centimetres, after

which reverse the feed direction to clean the blades.

Leave the tree into the feeder to remind you that the

chipper has been emptied. This way you will avoid a

possible jam when you turn on the chipper next time.

When you stop the chipper, wait for all

movement to stop. The grinding wheel

will continue to revolve like a flywheel

once the power outlet has been switched

off.

DANGER!

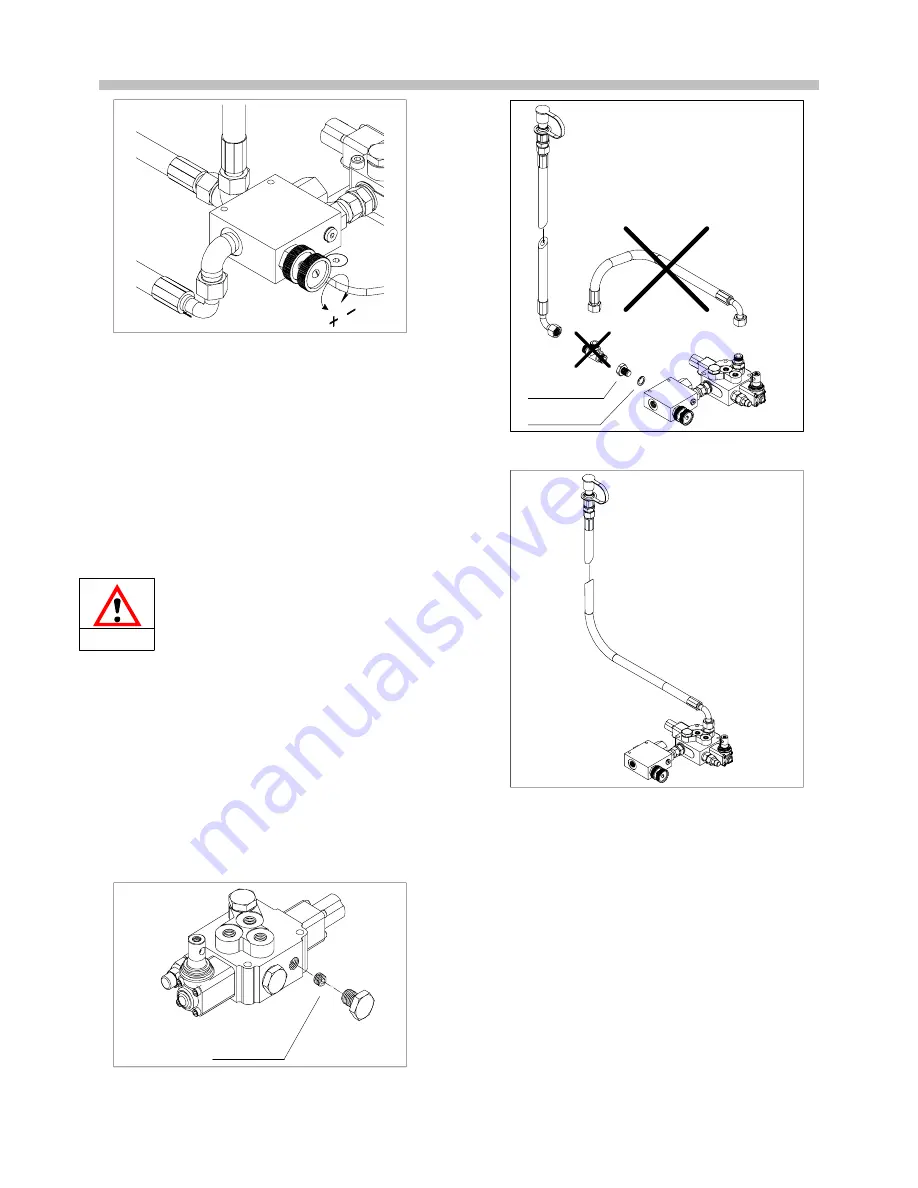

8.CHANGING THE HYDRAULIC UNIT

FOR USE WITH CONSTANT

PRESSURE PUMPS

The chipper valve is built for fixed displacement

pumps. If your tractor has a constant pressure

pump, the hydraulic feeder unit should be modified

as follows:

D

Insert a plug in the directional control valve -- see Fig 9.

D

Remove the hose and T--nipple and insert a plug in the

end of the flow regulator valve -- see Fig 10.

D

Connect the tank hose directly to the directional control

valve -- see Fig 11.

56075500

Fig 9.Inserting the plug.

52080819

52390200

Fig 10.Removing the hose and T--nipple and inserting the

plug in the end of the flow regulator valve.

Fig 11.Connecting the tank hose.

D

Instructions for connecting the hydraulics when using

the optional hydraulic unit can be found in hydraulic

units mounting instructions.

9.MAINTENANCE

D

The feed roller bearings are sealed and do not

require periodic maintenance.

D

Lubricate the roller bracket shaft slide bearings after

every 20 operating hours.

D

Check and tighten loose bolts at regular intervals.

D

Check the condition of the hydraulic hoses and

regularly inspect the connections for leaks.

D

Be sure to use only clean oil in the hydraulic system.

The presence of impurities in oil damages the valves

and hydraulic motors.

Summary of Contents for VALBY HF 231

Page 13: ...HF 231 13 10 HYDRAULICS CIRCUIT DIAGRAM Fig 12 43484050...

Page 14: ...HF 231 14 HF 231...

Page 16: ...HF 231 16 HF 231...

Page 27: ...27...

Page 28: ...28...

Page 31: ......

Page 32: ......