FARMI 380 HFC / HF

23

8h

8h

20h

MAINTENANCE

GENERAL MAINTENANCE INSTRUCTIONS

Position the chipper on solid, le-

vel ground to safeguard against

toppling. Always disconnect

the power-take-off and stop the

chipper and tractor fully before

embarking on maintenance or

repair work. The chipping disc

continues to rotate freely in the manner of a fly-

wheel after the power take-off has been discon-

nected.

WAIT UNTIL THE DISC COMPLETELY STOPS ROTA-

TING!

Lock the disc in place before commencing mainte-

nance and repair work.

Wear eye protection when handling the knives.

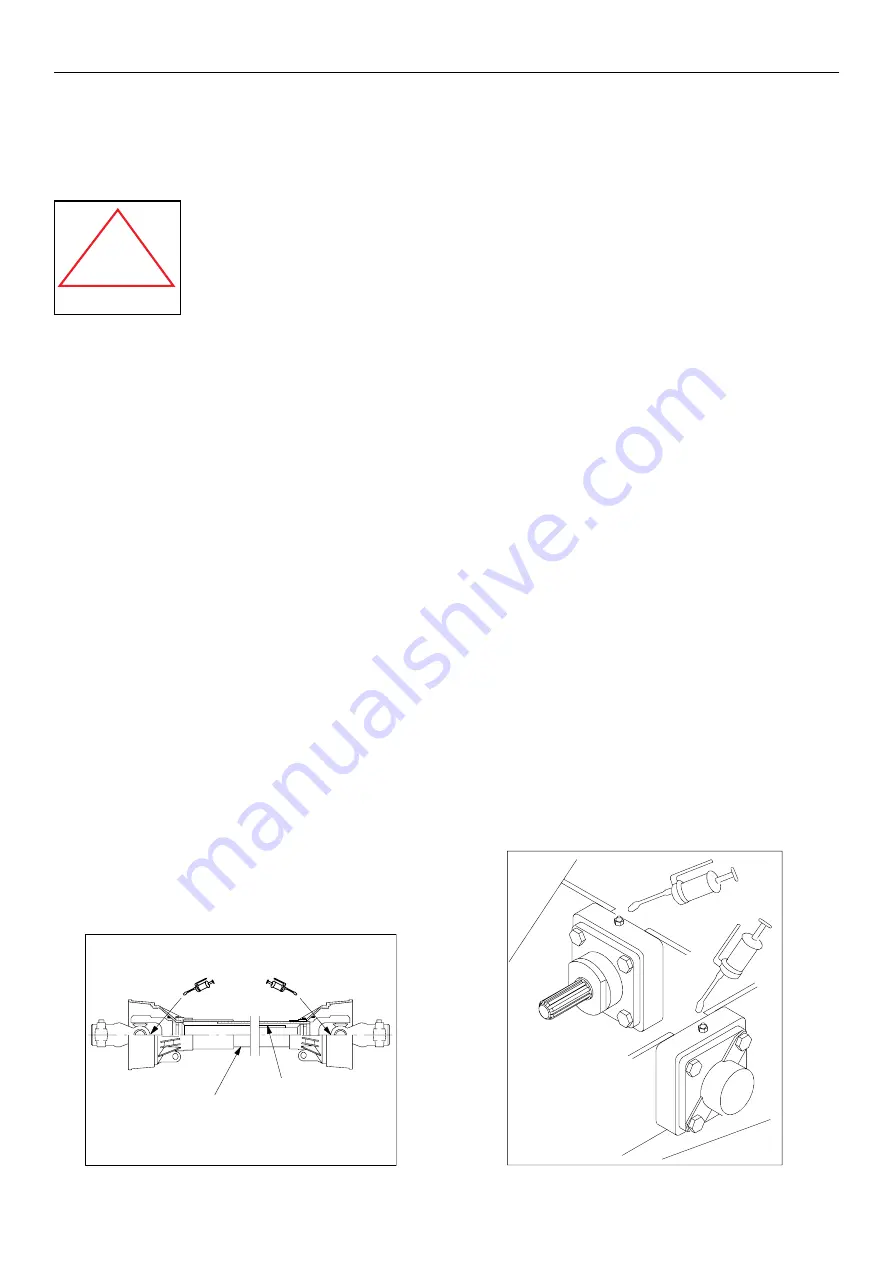

PTO SHAFT LUBRICATION

• Grease the PTO shaft before operating and at regu-

lar intervals as shown in the diagram.

• Grease the inner surface of the outermost PTO

shaft profile drive tube.

• In winter, grease the shaft shield tubes to prevent

freezing.

PERIODIC INSPECTIONS

• The tightness of the fastening bolts of a brand new

chipper must be checked after the first operating

hour and tightened as necessary. Tightening tor-

ques as shown in the table.

• The tightness of fastening bolts should be checked

on a weekly basis.

• The knife clearances must be adjusted

inaccordance with the given values. See the Knife

Clearance Adjustment instructions.

• Bearings are factory greased. Use high quality

grease for post-lubrication.

• The feed roller bearings are self-lubricating and do

not require regular maintenance.

• Grease the joint bearings of the roller swing at in-

tervals of 50 operating hours.

• Grease the disc bearings at intervals of 50 opera-

ting hours.

• Regularly monitor the condition and connection

tightness of the hydraulic hoses.

• Only use clean oil in the hydraulic system.

Dirty oil damages valves and hydraulic motors.

Move the joints back and forth sideways

when greasing.

In winter, grease the shaft

shield tubes to prevent

freezing.

Grease the inner surface of the

outermost profile drive tube.

h = operating hour

PTO shaft greasing points and greasing intervals

Bearing lubrication

CAUTION!

!

Summary of Contents for 380 HF Expert

Page 2: ......

Page 34: ...FARMI 380 HFC HF 34 ...

Page 35: ...FARMI 380 HFC HF 35 ...

Page 42: ...FARMI 380 HFC HF 42 1 10 9 8 7 6 5 4 3 2 11 9 7 12 13 11 12 HYDRAULIC UNIT HD380 ...

Page 48: ...FARMI 380 HFC HF 48 1 9 8 7 6 5 4 3 2 03801160 TWIG CRUSHER COMPLETE ...

Page 52: ...FARMI 380 HFC HF 52 1 10 9 8 7 6 5 4 3 2 11 FEED CHUTE HF380 ...

Page 54: ...FARMI 380 HFC HF 54 FEED CONVEYOR FC380 ...

Page 56: ...FARMI 380 HFC HF 56 9 7 6 5 4 3 2 11 15 12 21 24 23 HYDRAULICS ...

Page 58: ...FARMI 380 HFC HF 58 9 7 6 5 4 3 2 11 15 12 21 24 23 HYDRAULICS ...

Page 60: ...FARMI 380 HFC HF 60 ...

Page 61: ...FARMI 380 HFC HF 61 ...

Page 62: ...FARMI 380 HFC HF 62 43802900 ELECTRICS HF380 ...

Page 63: ...FARMI 380 HFC HF 63 ...

Page 67: ......